علامات المنتجات الساخنة

شفة مخفِّضة مخفِّضة مخفِّضة مخفِّضة

-معيار: ANSI / UL 213C FM

-المواد: حديد الدكتايل ASTM A536 ASTM A536، 65-45-12

-معدل الضغط: 300 - 500 رطل لكل بوصة مربعة

-السطح: طلاء أسود/طلاء أحمر/مغلفن بالغمس الساخن

-نطاق الحجم: 4”×4”×2-1/2”

الوصف

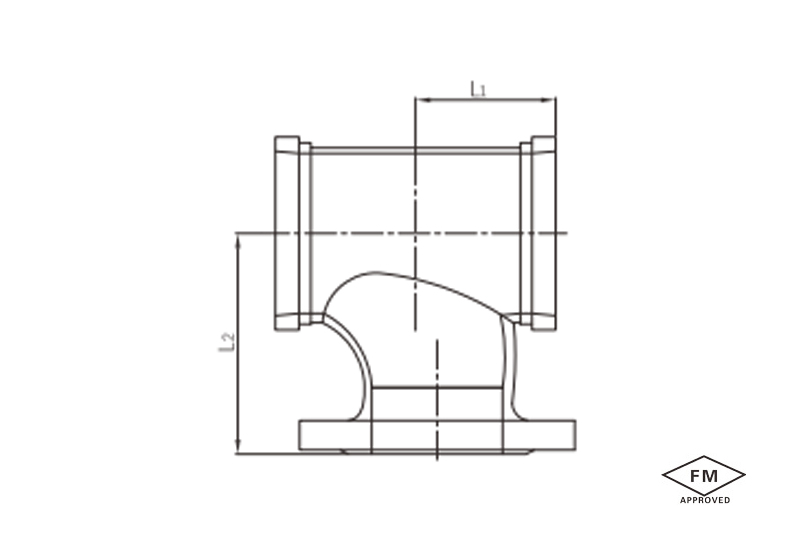

وصلة الحافة المخفِّضة المخفِّضة المخفِّضة هي عبارة عن تجهيزات أنابيب ذات هيكل توصيل مخفِّض وواجهة شفة في أحد طرفيها. تُستخدم للتفرع المائل لخطوط الأنابيب المختزلة والسيناريوهات التي تتطلب توصيل شفة

المواصفات

الحجم المتاح

| الحجم | المركز إلى النهاية (مم) | |||

| بوصة | دن | مم | L1 | L2 |

| 4” × 4” × 2-1/2” | 100 × 100 × 65 | 114.3 × 114.3 × 76.1 | 96 | 134.5 |

التطبيق

- الوصلة شبه اللحام: تُستخدم الوصلة شبه اللحام للأنظمة الفرعية المائلة التي تحتاج إلى التوصيل بين الأنابيب المحزوزة والمعدات ذات الحواف، مثل تكييف مخرج المضخة والصمام.

- مشروع بمساحة محدودة: يمكن أن يتكيف هذا النوع من التصميم مع متطلبات مشروع تجاوز خط الأنابيب، ويستخدم على نطاق واسع في المعدات الكثيفة، مثل المصانع الكيميائية وغرفة خط أنابيب محطة الطاقة.

- ترقية النظام وتمديده: جعل توصيل الأنابيب ذات الأقطار المختلفة وواجهة شفة المعدات (مثل الفلاتر وعدادات التدفق) أمرًا بسيطًا، وتقليل استخدام قطع المحول.

المزايا

1. متكامل متعدد الوظائف: حنفية قطعة واحدة ومخرج مقبس مع فتحات مسامير أفقية ورأسية لتوصيلات المياه الرئيسية، وتوصيلات فرعية ذات حواف تقليدية؛ تقليل 45 درجة لتقليل تعقيد التركيب

2. أمان الختم: أخدود مانع التسرب المحدد مسبقًا على أطراف الشفة يتوافق مع الحشيات القياسية؛ يتم إعادة إحكام الطرف ضد فك الارتباط، مما يحقق حماية ثنائية الاتجاه لإحكام الضغط العالي.

3. يوفر استخدام مادة حديد الدكتايل (ASTM A536) مقاومة فعالة للتآكل، بينما يمكن استخدام الطلاء الأسود/طلاء أحمر/معالجة السطح المجلفن بالغمس الساخن في الهواء الطلق لفترات طويلة.

4. فوائد التركيب: لا يوجد لحام عن طريق تصميم الأخدود والثقوب المحاذاة مسبقًا في مسامير الشفة مما يزيد من سرعة العمل في الموقع بأكثر من 50%.

5. شهادة دولية مناسبة: شهادة ANSI/UL/FM، إلى ضغط 300-500 رطل/بوصة مربعة للحماية من الحرائق والأنظمة الصناعية الآمنة للاستخدام

التعبئة

- حماية سطح وصلة الحافة: يتم إضافة غطاء بلاستيكي وغشاء مقاوم للصدأ إلى وصلات الشفة، ويتم استخدام سدادة سيليكون لسد ثقب البرغي لمنع التشويه

- تغليف مقوى متعدد الطبقات: يتم تضمين وحدة رغوة EPS في الجسم الرئيسي، ويضاف إطار دعم من الورق المقوى المموج إلى قسم الأنابيب الفرعية المائلة، وطبقة تعبئة كاملة مع الفولاذ داخل العلبة الخشبية.

- نظام تعريف ذكي: صندوق يحمل علامة السهم التي تشير إلى شفة علامة ↑ والتصنيف ورمز الاستجابة السريعة.

الحجم المتاح

| الحجم | المركز إلى النهاية (مم) | |||

| بوصة | دن | مم | L1 | L2 |

| 4” × 4” × 2-1/2” | 100 × 100 × 65 | 114.3 × 114.3 × 76.1 | 96 | 134.5 |

- الوصلة شبه اللحام: تُستخدم الوصلة شبه اللحام للأنظمة الفرعية المائلة التي تحتاج إلى التوصيل بين الأنابيب المحزوزة والمعدات ذات الحواف، مثل تكييف مخرج المضخة والصمام.

- مشروع بمساحة محدودة: يمكن أن يتكيف هذا النوع من التصميم مع متطلبات مشروع تجاوز خط الأنابيب، ويستخدم على نطاق واسع في المعدات الكثيفة، مثل المصانع الكيميائية وغرفة خط أنابيب محطة الطاقة.

- ترقية النظام وتمديده: جعل توصيل الأنابيب ذات الأقطار المختلفة وواجهة شفة المعدات (مثل الفلاتر وعدادات التدفق) أمرًا بسيطًا، وتقليل استخدام قطع المحول.

1. متكامل متعدد الوظائف: حنفية قطعة واحدة ومخرج مقبس مع فتحات مسامير أفقية ورأسية لتوصيلات المياه الرئيسية، وتوصيلات فرعية ذات حواف تقليدية؛ تقليل 45 درجة لتقليل تعقيد التركيب

2. أمان الختم: أخدود مانع التسرب المحدد مسبقًا على أطراف الشفة يتوافق مع الحشيات القياسية؛ يتم إعادة إحكام الطرف ضد فك الارتباط، مما يحقق حماية ثنائية الاتجاه لإحكام الضغط العالي.

3. يوفر استخدام مادة حديد الدكتايل (ASTM A536) مقاومة فعالة للتآكل، بينما يمكن استخدام الطلاء الأسود/طلاء أحمر/معالجة السطح المجلفن بالغمس الساخن في الهواء الطلق لفترات طويلة.

4. فوائد التركيب: لا يوجد لحام عن طريق تصميم الأخدود والثقوب المحاذاة مسبقًا في مسامير الشفة مما يزيد من سرعة العمل في الموقع بأكثر من 50%.

5. شهادة دولية مناسبة: شهادة ANSI/UL/FM، إلى ضغط 300-500 رطل/بوصة مربعة للحماية من الحرائق والأنظمة الصناعية الآمنة للاستخدام

- حماية سطح وصلة الحافة: يتم إضافة غطاء بلاستيكي وغشاء مقاوم للصدأ إلى وصلات الشفة، ويتم استخدام سدادة سيليكون لسد ثقب البرغي لمنع التشويه

- تغليف مقوى متعدد الطبقات: يتم تضمين وحدة رغوة EPS في الجسم الرئيسي، ويضاف إطار دعم من الورق المقوى المموج إلى قسم الأنابيب الفرعية المائلة، وطبقة تعبئة كاملة مع الفولاذ داخل العلبة الخشبية.

- نظام تعريف ذكي: صندوق يحمل علامة السهم التي تشير إلى شفة علامة ↑ والتصنيف ورمز الاستجابة السريعة.

احصل على عرض أسعار أنابيب الصلب المخصصة اليوم!

زوّدنا بتفاصيل مشروعك (مثل التطبيق والمواصفات والكمية). سيقدم لك فريقنا المتمرس حلاً مخصصاً وعرض أسعار تنافسي في غضون 24 ساعة عمل.