HOT PRODUCTS TAGS

Grooved reducing flange tee wye

·Standard: ANSI / UL 213C FM

·Material: Ductile iron ASTM A536, 65-45-12

·Rated pressure: 300 – 500 psi

·Surface: Black / red painting / hot dip galvanized

·Size range: 4”×4”×2-1/2”

description

Grooved reducing flange tee wye is a pipe fitting with a grooved connection structure and a flange interface at one end. It is used for the diagonal branch of reducing pipelines and scenarios where flange connection is required

Specification

Available size

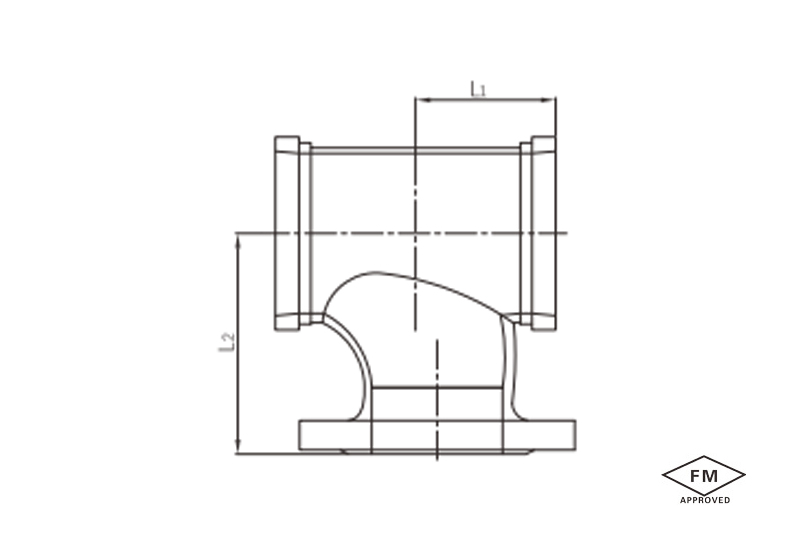

| Size | Center to end(mm) | |||

| Inch | DN | mm | L1 | L2 |

| 4” × 4” × 2-1/2” | 100 × 100 × 65 | 114.3 × 114.3 × 76.1 | 96 | 134.5 |

application

- Semi-weld connection: The Semi-Weld connection is utilized for the inclined branch systems that need to be connected between grooved pipes and flanged equipment, like pump and valve outlet adaptation.

- Project with space restricted: This kind of design can adapt to the requirement of pipeline bypass project, and is widely used in dense equipment, such as chemical plants and energy station pipeline room.

- System upgrade and extension: make the connection of different diameter pipes and flange interface of equipment (such as filters, flow meters) is simple, reduce the use of adapter pieces.

advantages

1. Integrated multi-functions: single piece spigot and socket outlet with horizontal and vertical bolt holes for water main connections, conventional flanged branch connections; 45-degree reduction reducing installation complexity

2. Sealing security: Pre-set sealing groove on flange ends conforms to standard gaskets; end is re-tightened against disengagement, realizing two-way protection of high-pressure tightness.

3. Utilizing a Ductile iron material (ASTM A536) provides effective corrosion resistance, while black paint / red paint / hot-dip galvanized surface treatment can be used outdoors for extended periods.

4. Installation Benefits: No welding by groove design and pre aligned holes in the flange bolts which increase the on site work speed by more than 50%.

5. Certification proper international: ANSI/UL/FM certification, to 300-500 psi pressure maintained fire protection and industrial systems are safe to use

packing

- Protection of flange joint surface: Plastic cap and rust-proof film are added to the flange joints, silicone plug is used to block bolt hole to prevent distortion

- Layered reinforcement packaging: the EPS foam module is embedded in the main body, corrugated cardboard support frame is added to the inclined branch pipe section, and a whole packing layer with steel inside wooden case.

- Smart identification system: Box marked with arrow marking the flange of ↑ sign, rating and QR code.

Available size

| Size | Center to end(mm) | |||

| Inch | DN | mm | L1 | L2 |

| 4” × 4” × 2-1/2” | 100 × 100 × 65 | 114.3 × 114.3 × 76.1 | 96 | 134.5 |

- Semi-weld connection: The Semi-Weld connection is utilized for the inclined branch systems that need to be connected between grooved pipes and flanged equipment, like pump and valve outlet adaptation.

- Project with space restricted: This kind of design can adapt to the requirement of pipeline bypass project, and is widely used in dense equipment, such as chemical plants and energy station pipeline room.

- System upgrade and extension: make the connection of different diameter pipes and flange interface of equipment (such as filters, flow meters) is simple, reduce the use of adapter pieces.

1. Integrated multi-functions: single piece spigot and socket outlet with horizontal and vertical bolt holes for water main connections, conventional flanged branch connections; 45-degree reduction reducing installation complexity

2. Sealing security: Pre-set sealing groove on flange ends conforms to standard gaskets; end is re-tightened against disengagement, realizing two-way protection of high-pressure tightness.

3. Utilizing a Ductile iron material (ASTM A536) provides effective corrosion resistance, while black paint / red paint / hot-dip galvanized surface treatment can be used outdoors for extended periods.

4. Installation Benefits: No welding by groove design and pre aligned holes in the flange bolts which increase the on site work speed by more than 50%.

5. Certification proper international: ANSI/UL/FM certification, to 300-500 psi pressure maintained fire protection and industrial systems are safe to use

- Protection of flange joint surface: Plastic cap and rust-proof film are added to the flange joints, silicone plug is used to block bolt hole to prevent distortion

- Layered reinforcement packaging: the EPS foam module is embedded in the main body, corrugated cardboard support frame is added to the inclined branch pipe section, and a whole packing layer with steel inside wooden case.

- Smart identification system: Box marked with arrow marking the flange of ↑ sign, rating and QR code.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.