علامات المنتجات الساخنة

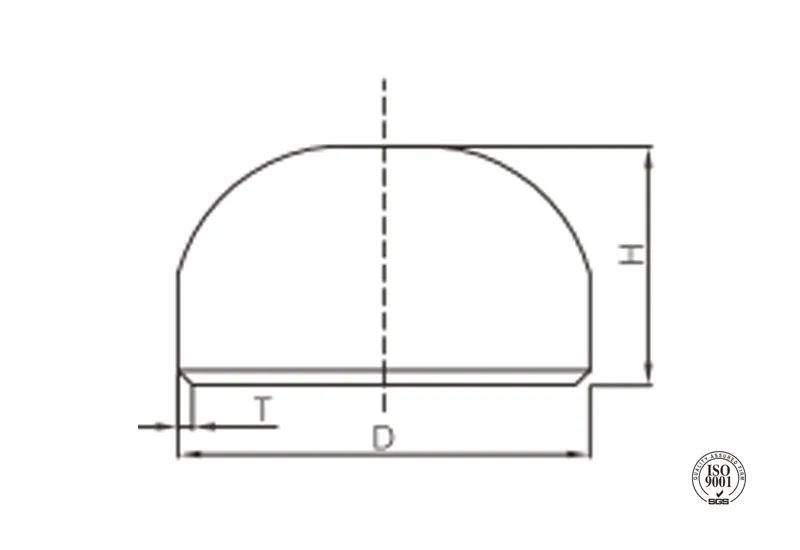

غطاء اللحام التناكبي

-معيار: الأيزو

إن 10253-1 / إن 10253-2 / إن 10253-3

-المواد: فولاذ الكربون S235 / P235TR2

إس إس مكافئ ل WP304/ WP316L

-الضغط: يساوي نفس الأنبوب المستقيم

-السطح: طلاء أسود/مغلفن بالغمس الساخن

مخلل أبيض، إلخ.

-نطاق الحجم: 1″-24″

الوصف

تشكِّل أغطية اللحام التناكبي مانع تسرب عالي القوة من خلال وصلات اللحام التناكبي، والتي يمكنها تحمل الضغط العالي بشكل موثوق ومنع التسرب.

المواصفات

الحجم المتاح

| الحجم | المفضل T إلى EN 10253-2 (مم) | ص (مم) | ||

| NPS | دن | OD (مم) | ||

| 1/2″ | 15 | 21.3 | 2.0/2.6/3.214.0/5.017.1 | 25 |

| 3/4″ | 20 | 26.9 | 2.3/2.6/3.214.014.5/5.6/8.0 | 25 |

| 1″ | 25 | 33.7 | 2.6/3.214.014.515.6/6.3/8.8 | 25 |

| 1-1/4″ | 32 | 42.4 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 38 |

| 1-1/2″ | 40 | 48.3 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 38 |

| 2″ | 50 | 60.3 | 2.9/3.614.0/5.6/7.1/8.8/11.0 | 38 |

| 2-1/2″ | 65 | 76.1 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 38 |

| 3″ | 80 | 88.9 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 51 |

| 4″ | 100 | 114.3 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 64 |

| 5″ | 125 | 139.7 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 76 |

| 6″ | 150 | 165.1/168.3 | 4.0/4.5/5.6/7.1/11.0/14.2/17.5122.2 | 89 |

| 8″ | 200 | 219.1 | 4.5/6.3/7.1/8.0/12.5/16.0/17.5122.2 | 102 |

| 10″ | 250 | 273.0 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 127 |

| 12″ | 300 | 323.9 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 152 |

| 14″ | 350 | 355.6 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 165 |

| 16″ | 400 | 406.4 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 178 |

| 18″ | 450 | 457 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 203 |

| 20″ | 500 | 508 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 229 |

| 24″ | 600 | 610 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 267 |

التطبيق

- تُستخدم للإغلاق النهائي الدائم لأنظمة الأنابيب لتحقيق الإغلاق المطلق للسوائل عالية الضغط، كما هو الحال في نهايات خطوط أنابيب المعالجة، والواجهات المحجوزة للمعدات، وأقسام عزل النظام.

- تشمل التطبيقات الرئيسية منصات النفط، ومعدات التفاعل الكيميائي، وأنظمة البخار عالية الضغط، والظروف الخطرة الأخرى التي تتطلب عدم وجود تسرب.

- يستخدم كعنصر عزل آمن أثناء اختبار ضغط خط الأنابيب وصيانة قسم النظام.

المزايا

- بوليصة التأمين النهائية لإحكام الإغلاق: نوع نصف كروي/فراشة + وصلات ملحومة بالكامل، قدرة إجهاد كبيرة تجعل من الصعب للغاية إنتاج تسرب من الأنبوب المستقيم.

- تصميم مقاوم للصدمات: يمكن للتكوين المنحني السميك أن يتحمل تأثير المطرقة المائية وتقلبات الضغط، وعامل الأمان أعلى من المعيار بأكثر من 3 مرات.

- مصفوفة الدفاع ضد التآكل الفولاذ الكربوني: طلاء مسحوق الإيبوكسي شديد التحمل المضاد للتآكل (≥250 ميكرومتر) أو الجلفنة بالغمس الساخن لمدة 20 عامًا مقاومة للعوامل الجويةالفولاذ المقاوم للصدأ: تلميع كهربائيا (Ra≤8 ميكرومتر)، يتوافق مع ASME BPE.

- ثورة التركيب: تحل الوصلة الملحومة أحادية القطعة محل تركيبات الشفة ذات الحافة العمياء، مما يوفر وقت التركيب 80% ويزيل مخاطر فك البراغي.

- مجموعة كبيرة من المقاسات: نطاق كامل من 1 بوصة إلى 24 بوصة، للاستخدام مع الأنابيب ذات الجدران العميقة للغاية (SCH160) وأنظمة السبائك الخاصة.

التعبئة

- عبوات متداخلة مقاومة للضغط:

- ≤10″: صندوق مموج عالي القوة + بطانة داخلية مصبوبة من EPS

- 10″: صندوق خشبي مقوى بالفولاذ + إطار دعم داخلي من الألومنيوم على شكل قرص العسل

- ختم حماية مزدوج الطبقة:

- سطح داخلي: ورق مقاوم للصدأ قابل للتحلل الحيوي من الدرجة الغذائية

- السطح الخارجي: غلاف غشاء يتقلص بالحرارة + واقيات زوايا مقاومة للصدمات

- نظام ذكي للتدقيق في الأخطاء:

- إرشادات معالجة شطبة اللحام المطبوعة على الجانب الداخلي للعبوة

- شريط تحذير فلوري (مع ملصق “ممنوع التأثير”) ملصق على العلبة الخارجية

- إمكانية التتبع البسيطة: منقوش بالليزر على الجدار الداخلي لغطاء الأنبوب، يجمع بين ثلاثة رموز (المواصفات/ تصنيف الضغط/ رقم دفعة المواد).

الحجم المتاح

| الحجم | المفضل T إلى EN 10253-2 (مم) | ص (مم) | ||

| NPS | دن | OD (مم) | ||

| 1/2″ | 15 | 21.3 | 2.0/2.6/3.214.0/5.017.1 | 25 |

| 3/4″ | 20 | 26.9 | 2.3/2.6/3.214.014.5/5.6/8.0 | 25 |

| 1″ | 25 | 33.7 | 2.6/3.214.014.515.6/6.3/8.8 | 25 |

| 1-1/4″ | 32 | 42.4 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 38 |

| 1-1/2″ | 40 | 48.3 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 38 |

| 2″ | 50 | 60.3 | 2.9/3.614.0/5.6/7.1/8.8/11.0 | 38 |

| 2-1/2″ | 65 | 76.1 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 38 |

| 3″ | 80 | 88.9 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 51 |

| 4″ | 100 | 114.3 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 64 |

| 5″ | 125 | 139.7 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 76 |

| 6″ | 150 | 165.1/168.3 | 4.0/4.5/5.6/7.1/11.0/14.2/17.5122.2 | 89 |

| 8″ | 200 | 219.1 | 4.5/6.3/7.1/8.0/12.5/16.0/17.5122.2 | 102 |

| 10″ | 250 | 273.0 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 127 |

| 12″ | 300 | 323.9 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 152 |

| 14″ | 350 | 355.6 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 165 |

| 16″ | 400 | 406.4 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 178 |

| 18″ | 450 | 457 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 203 |

| 20″ | 500 | 508 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 229 |

| 24″ | 600 | 610 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 267 |

- تُستخدم للإغلاق النهائي الدائم لأنظمة الأنابيب لتحقيق الإغلاق المطلق للسوائل عالية الضغط، كما هو الحال في نهايات خطوط أنابيب المعالجة، والواجهات المحجوزة للمعدات، وأقسام عزل النظام.

- تشمل التطبيقات الرئيسية منصات النفط، ومعدات التفاعل الكيميائي، وأنظمة البخار عالية الضغط، والظروف الخطرة الأخرى التي تتطلب عدم وجود تسرب.

- يستخدم كعنصر عزل آمن أثناء اختبار ضغط خط الأنابيب وصيانة قسم النظام.

- بوليصة التأمين النهائية لإحكام الإغلاق: نوع نصف كروي/فراشة + وصلات ملحومة بالكامل، قدرة إجهاد كبيرة تجعل من الصعب للغاية إنتاج تسرب من الأنبوب المستقيم.

- تصميم مقاوم للصدمات: يمكن للتكوين المنحني السميك أن يتحمل تأثير المطرقة المائية وتقلبات الضغط، وعامل الأمان أعلى من المعيار بأكثر من 3 مرات.

- مصفوفة الدفاع ضد التآكل الفولاذ الكربوني: طلاء مسحوق الإيبوكسي شديد التحمل المضاد للتآكل (≥250 ميكرومتر) أو الجلفنة بالغمس الساخن لمدة 20 عامًا مقاومة للعوامل الجويةالفولاذ المقاوم للصدأ: تلميع كهربائيا (Ra≤8 ميكرومتر)، يتوافق مع ASME BPE.

- ثورة التركيب: تحل الوصلة الملحومة أحادية القطعة محل تركيبات الشفة ذات الحافة العمياء، مما يوفر وقت التركيب 80% ويزيل مخاطر فك البراغي.

- مجموعة كبيرة من المقاسات: نطاق كامل من 1 بوصة إلى 24 بوصة، للاستخدام مع الأنابيب ذات الجدران العميقة للغاية (SCH160) وأنظمة السبائك الخاصة.

- عبوات متداخلة مقاومة للضغط:

- ≤10″: صندوق مموج عالي القوة + بطانة داخلية مصبوبة من EPS

- 10″: صندوق خشبي مقوى بالفولاذ + إطار دعم داخلي من الألومنيوم على شكل قرص العسل

- ختم حماية مزدوج الطبقة:

- سطح داخلي: ورق مقاوم للصدأ قابل للتحلل الحيوي من الدرجة الغذائية

- السطح الخارجي: غلاف غشاء يتقلص بالحرارة + واقيات زوايا مقاومة للصدمات

- نظام ذكي للتدقيق في الأخطاء:

- إرشادات معالجة شطبة اللحام المطبوعة على الجانب الداخلي للعبوة

- شريط تحذير فلوري (مع ملصق “ممنوع التأثير”) ملصق على العلبة الخارجية

- إمكانية التتبع البسيطة: منقوش بالليزر على الجدار الداخلي لغطاء الأنبوب، يجمع بين ثلاثة رموز (المواصفات/ تصنيف الضغط/ رقم دفعة المواد).

احصل على عرض أسعار أنابيب الصلب المخصصة اليوم!

زوّدنا بتفاصيل مشروعك (مثل التطبيق والمواصفات والكمية). سيقدم لك فريقنا المتمرس حلاً مخصصاً وعرض أسعار تنافسي في غضون 24 ساعة عمل.