HOT PRODUCTS TAGS

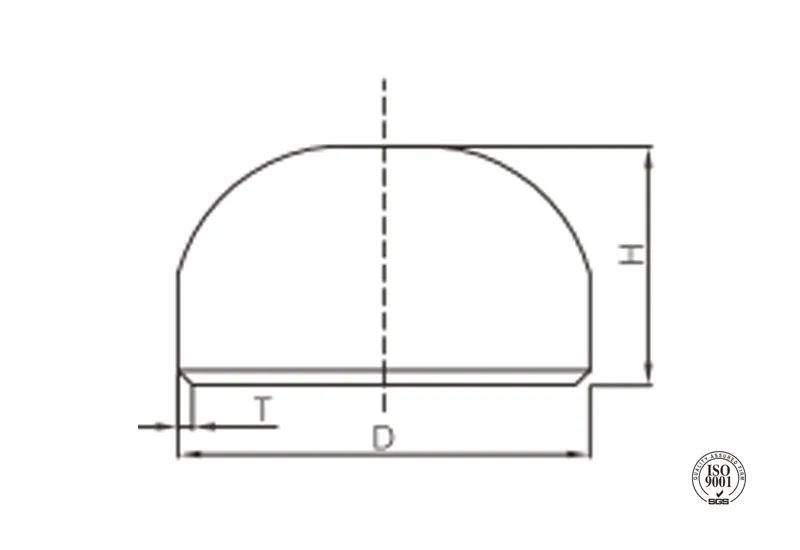

Butt weld cap

·Standard: ISO

EN 10253-1 / EN 10253-2 / EN 10253-3

·Material: Carbon steel S235 / P235TR2

SS equivalent to WP304 / WP316L

·W. pressure: Equal to same straight pipe

·Surface: Black painting / hot dip galvanized

Pickling white, etc.

·Size range: 1″-24″

description

butt weld caps form a high-strength seal through butt welding connections, which can reliably withstand high pressure and prevent leakage.

Specification

Available size

| Size | Preferred T to EN 10253-2(mm) | R(mm) | ||

| NPS | DN | OD(mm) | ||

| 1/2″ | 15 | 21.3 | 2.0/2.6/3.214.0/5.017.1 | 25 |

| 3/4″ | 20 | 26.9 | 2.3/2.6/3.214.014.5/5.6/8.0 | 25 |

| 1″ | 25 | 33.7 | 2.6/3.214.014.515.6/6.3/8.8 | 25 |

| 1-1/4″ | 32 | 42.4 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 38 |

| 1-1/2″ | 40 | 48.3 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 38 |

| 2″ | 50 | 60.3 | 2.9/3.614.0/5.6/7.1/8.8/11.0 | 38 |

| 2-1/2″ | 65 | 76.1 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 38 |

| 3″ | 80 | 88.9 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 51 |

| 4″ | 100 | 114.3 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 64 |

| 5″ | 125 | 139.7 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 76 |

| 6″ | 150 | 165.1/168.3 | 4.0/4.5/5.6/7.1/11.0/14.2/17.5122.2 | 89 |

| 8″ | 200 | 219.1 | 4.5/6.3/7.1/8.0/12.5/16.0/17.5122.2 | 102 |

| 10″ | 250 | 273.0 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 127 |

| 12″ | 300 | 323.9 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 152 |

| 14″ | 350 | 355.6 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 165 |

| 16″ | 400 | 406.4 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 178 |

| 18″ | 450 | 457 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 203 |

| 20″ | 500 | 508 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 229 |

| 24″ | 600 | 610 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 267 |

application

- Used for permanent terminal closure of piping systems to achieve absolute sealing of high-pressure fluids, such as at the ends of process pipelines, equipment reserved interfaces, and system isolation sections.

- Key applications include oil platforms, chemical reaction equipment, high-pressure steam systems, and other hazardous conditions that require zero leakage.

- Used as a safety isolation component during pipeline pressure testing and system section maintenance.

advantages

- The final sealing insurance policy: hemispherical/butterfly type + fully welded joints, quite stressing capacity rendering the straight pipe extremely hard to produce leak.

- Impact-Resistant Design: The thickened curved configuration can bear water hammer impact and pressure fluctuations, safety factor more than 3 times higher than the standard.

- Corrosion Defense Matrix: Carbon Steel: Heavy duty anti-corrosive epoxy powder coating (≥250μm) or hot-dip galvanizing 20 years weather resistanceStainless Steel: Electrolytic polishing finish(Ra≤8 μm), conforms to ASME BPE.

- Installation Revolution: single-piece welded connection replaces flange-blind flange combinations, saving 80% installation time and eliminating bolt loosening risks.

- Large Range of Sizes: 1”- 24” full range, for use with ultra-deep-walled pipe (SCH160) and special alloy systems.

packing

- Compression-resistant nested packaging:

- ≤10″: High-strength corrugated box + EPS molded inner liner

- 10″: Steel-reinforced wooden box + internal honeycomb aluminum support frame

- Dual-layer protective sealing:

- Inner surface: Food-grade biodegradable rust-proof paper

- Outer surface: Heat-shrink film packaging + impact-resistant corner guards

- Smart error-proofing system:

- Printed welding bevel processing guidelines on the inner side of the packaging

- Fluorescent warning tape (with “No Impact” label) affixed to the outer box

- Minimalist traceability: Laser-engraved on the inner wall of the pipe cap, combining three codes (specification/pressure rating/material batch number).

Available size

| Size | Preferred T to EN 10253-2(mm) | R(mm) | ||

| NPS | DN | OD(mm) | ||

| 1/2″ | 15 | 21.3 | 2.0/2.6/3.214.0/5.017.1 | 25 |

| 3/4″ | 20 | 26.9 | 2.3/2.6/3.214.014.5/5.6/8.0 | 25 |

| 1″ | 25 | 33.7 | 2.6/3.214.014.515.6/6.3/8.8 | 25 |

| 1-1/4″ | 32 | 42.4 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 38 |

| 1-1/2″ | 40 | 48.3 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 38 |

| 2″ | 50 | 60.3 | 2.9/3.614.0/5.6/7.1/8.8/11.0 | 38 |

| 2-1/2″ | 65 | 76.1 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 38 |

| 3″ | 80 | 88.9 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 51 |

| 4″ | 100 | 114.3 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 64 |

| 5″ | 125 | 139.7 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 76 |

| 6″ | 150 | 165.1/168.3 | 4.0/4.5/5.6/7.1/11.0/14.2/17.5122.2 | 89 |

| 8″ | 200 | 219.1 | 4.5/6.3/7.1/8.0/12.5/16.0/17.5122.2 | 102 |

| 10″ | 250 | 273.0 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 127 |

| 12″ | 300 | 323.9 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 152 |

| 14″ | 350 | 355.6 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 165 |

| 16″ | 400 | 406.4 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 178 |

| 18″ | 450 | 457 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 203 |

| 20″ | 500 | 508 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 229 |

| 24″ | 600 | 610 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 267 |

- Used for permanent terminal closure of piping systems to achieve absolute sealing of high-pressure fluids, such as at the ends of process pipelines, equipment reserved interfaces, and system isolation sections.

- Key applications include oil platforms, chemical reaction equipment, high-pressure steam systems, and other hazardous conditions that require zero leakage.

- Used as a safety isolation component during pipeline pressure testing and system section maintenance.

- The final sealing insurance policy: hemispherical/butterfly type + fully welded joints, quite stressing capacity rendering the straight pipe extremely hard to produce leak.

- Impact-Resistant Design: The thickened curved configuration can bear water hammer impact and pressure fluctuations, safety factor more than 3 times higher than the standard.

- Corrosion Defense Matrix: Carbon Steel: Heavy duty anti-corrosive epoxy powder coating (≥250μm) or hot-dip galvanizing 20 years weather resistanceStainless Steel: Electrolytic polishing finish(Ra≤8 μm), conforms to ASME BPE.

- Installation Revolution: single-piece welded connection replaces flange-blind flange combinations, saving 80% installation time and eliminating bolt loosening risks.

- Large Range of Sizes: 1”- 24” full range, for use with ultra-deep-walled pipe (SCH160) and special alloy systems.

- Compression-resistant nested packaging:

- ≤10″: High-strength corrugated box + EPS molded inner liner

- 10″: Steel-reinforced wooden box + internal honeycomb aluminum support frame

- Dual-layer protective sealing:

- Inner surface: Food-grade biodegradable rust-proof paper

- Outer surface: Heat-shrink film packaging + impact-resistant corner guards

- Smart error-proofing system:

- Printed welding bevel processing guidelines on the inner side of the packaging

- Fluorescent warning tape (with “No Impact” label) affixed to the outer box

- Minimalist traceability: Laser-engraved on the inner wall of the pipe cap, combining three codes (specification/pressure rating/material batch number).

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.