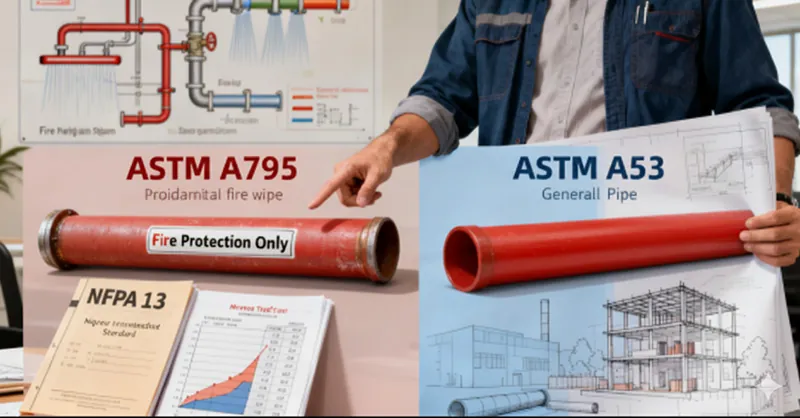

ASTM A795 vs. ASTM A53: Choosing Fire Sprinkler Pipe

Imagine that an engineer is reviewing the fire-fighting drawings and discussing the pipeline standards: ASTM A795 or ASTM A53? This choice is not simple-it determines the compliance, emergency performance, and budget. For engineers, missteps here risk catastrophic failures in critical moments, such as pipe bursts mid-fire or inadequate water flow to contain flames.

The core distinction: ASTM A795 is a dedicated sprinkler pipe standard, while ASTM A53 is a general-purpose pipe standard. Although ASTM A53 is widely available and cost-effective in the early stage, its requirements are not aimed at the unique pressure source of fire fighting. By using quantitative data and industry guidelines, this paper provides a feasible framework for engineers to choose the right fire sprinkler.

The Standards Explained

ASTM A53: General-Purpose Pipe

ASTM A53 is the highest standard for building piping, but it is not designed for fire sprinkler piping systems. Seamless/welded carbon steel pipes formulated by ASTM international standards cover “pressure and mechanical applications” (ASTM international standards, 2024), including water distribution, gas transmission pipelines and structural support, but excluding fire fighting.

ASTM A795: The Dedicated Fire Protection Standard

ASTM A795 was created exclusively for fire sprinkler pipe systems. Every requirement, from material strength to test protocol, ensures that it can withstand the strict requirements of fire fighting. ASTM International Organization for Standards points out that it covers “seamless and welded carbon steel pipe for fire fighting”, with emphasis on “reliability under fire conditions” (ASTM International Organization for Standards, 2024).

The main advantages of using sprinkler pipe are: stricter weld quality control (including 100% visual inspection of welds, because weak welds are the main failure points of fire fighting systems) and mandatory chemical components for corrosion resistance, which are very important for wet fire fighting sprinkler pipe systems that store water all year round. Unlike ASTM A53, it is an expert-transforming it into consistent and reliable safety in fire scenes.

(Source: ASTM A795 Standard Specification for Pipe, Steel, Black, Welded and Seamless, for Fire Protection Service.)

Quantitative Head-to-Head Comparison

The following is a data-driven comparison using ASTM standards and NFPA (the authoritative organization of fire safety) guidelines.

| Feature | ASTM A795 (dedicated fire sprinkler pipe) | ASTM A53 (General-Purpose Pipe) |

| Main usage | Special fire sprinkler/fire protection | General pressure/mechanical application and structural support |

| Hydraulic pressure test | All pipes must be ≥ 1,000 psi for 10 minutes without leakage (ASTM A795, Section 8.2) | Required, but variable: Calculated based on pipe size and grade, typically lower than the specific high-pressure requirements for fire systems; Different duration (ASTM A53, Section 9) |

| Non destructive testing | It is mandatory for ERW pipes (all welds pass ultrasonic test, etc.) (ASTM A795, Section 8.3) | In most cases, optional; Only ERW pipes larger than 24 inches are required (ASTM A53, Section 9.3) |

| Weldable property | Optimization for grooving/welding (important for sprinkler pipe connections); Weld seam quality is strictly controlled to maintain high tensile strength, ensuring reliability. | Suitable for general purposes, not for fire sprinkler pipe; There is no requirement for tensile strength of weld |

| Anticorrosion performance | Designed for long service life in wet systems. Suitable for galvanizing and often has a greater minimum wall thickness for corrosion allowance. | Corrosion resistance is not a primary focus of the standard. Protection relies on optional coatings (e.g., galvanizing) and the specified pipe schedule. |

| Sign Requirements | “ASTM A795”, manufacturer, dimensions, list, “Fire protection only” (ASTM A795, Section 10) | Only “ASTM A53” grade and size; Non-fire adaptability indicator |

| NFPA protocol 13 compliance | Automatic compliance with NFPA 13 (sprinkler piping standard) (NFPA, 2023) | Needs extra-testing/docs; Not all grades are NFPA-approved |

(Source: NFPA 13 Standard for the Installation of Sprinkler Systems.)

Conclusion: An operable Decision

For engineers who design fire sprinkler piping systems, it is safe or short-term convenient to choose. ASTM A795’s dedicated design—mandatory high-pressure testing, corrosion resistance, and weld inspections—meets strict standards like NFPA 13. ASTM A53, though versatile, lacks these fire-specific safeguards, making it riskier unless explicitly approved.

When do you choose ASTM A795

All new fire sprinkler systems (commercial buildings, hospitals, schools) have the sole purpose of preventing fire.

Projects that conform to NFPA Protocol 13 are required (eliminating extra testing and document delays).

High-risk applications (high-rise buildings, flammable material facilities), in which the failure of sprinkler pipe could cause casualties.

When to Consider ASTM A53 standard

Dual purpose tube (e.g., Sprinkler pipe+structural support) -Only after obtaining the written approval from the chief engineer and local fire chief.

Retrofit the existing ASTM A53 where it meets NFPA 13 (it is well documented that it meets the threshold of fire resistance).

Fire sprinkler systems is the last line of defense for building fires prevention. ASTM A795 is not only a standard, but also a performance guarantee that counts against time. For engineers, this is a decision worthy of support.

Share:

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.