Yield Strength vs Tensile Strength: Guide to Pipeline Safety

Introduction

When you’re buying steel pipe for a critical infrastructure project—whether it’s LSAW or SSAW steel pipe for a major gas pipeline or seamless pipe for a structural foundation—the technical specification sheet is the most important piece of paper on your desk.. It’s a dense wall of numbers and codes, but out of all that data, two values are the most important in determining the physical integrity and ultimate safety of your project: Yield Strength and Tensile Strength.

Knowing the difference between these two properties is not just an academic exercise. It is a basic tenet of prudent engineering, purchasing, and risk management. A misunderstanding can cause catastrophic results such as cost overruns from material failure, environmental harm from leaks, and in the worst scenarios, disastrous structural collapse. To really understand what these numbers mean for the steel you’re buying, we have to put aside the complicated formulas and look at a simple, intuitive analogy that tells the whole story: stretching a common elastic band.

What is Yield Strength?

Take an elastic band from your desk. Pull it gently, stretching it to a moderate length, and then let it go. It snaps back to its original size, completely unharmed. This is what’s called elastic deformation in materials science. It is the condition that your pipeline is supposed to live in for its entire service life. During the normal, pulsating pressures of operation, the steel is repeatedly bending and subjected to tremendous forces, but it invariably comes back to its original form, as if it were waiting for the next pulse.

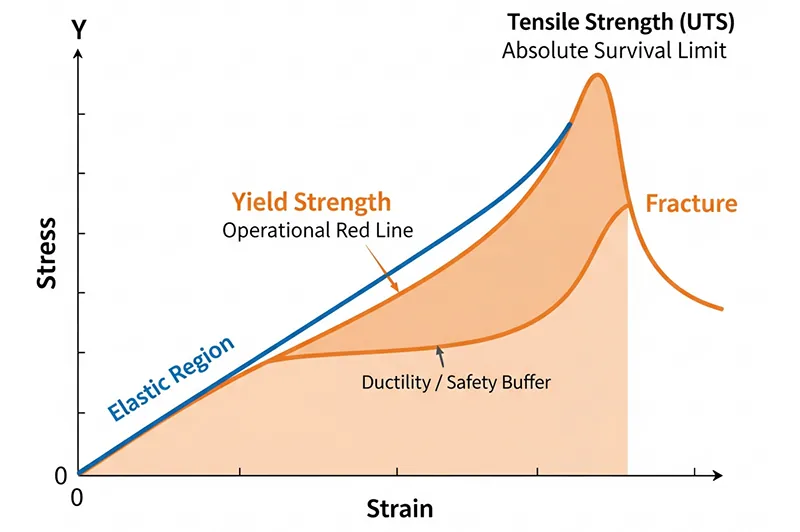

Now, pull that elastic band again, but this time, pull it harder until you feel a distinct change in its resistance. When you let it go this time, you’ll see it doesn’t fully retract. It’s visibly longer, permanently stretched and weakened. That exact instant of transition — from a temporary, elastic stretch to a permanent, plastic deformation — is the yield point.The amount of stress you have to put on a material to get there is the material’s Yield Strength.

What This Means for Pipeline Safety:

In a steel pipe, going beyond the yield strength is when a temporary stress becomes permanent damage. Although the pipe may not have burst, it is now weakened. Such “damage” may take the form of localized thinning, a loss of perfect roundness , or the development of microscopic cracks that may expand with time.

So you should consider the yield strength as the absolute “red lin” for everyday operations. The Maximum Allowable Operating Pressure (MAOP) of any pipeline is derived as a fraction of the yield strength of the material. This provides a vital safety margin, so that even if there are unexpected pressure surges, the pipe will still be well within the elastic region. Going beyond this limit pushes the pipeline beyond its design limits and into a state of rapid fatigue and danger.

What is Tensile Strength?

Let’s go back to our stretched out elastic band. It’s compromised, but not shattered yet. If you keep pulling on it, it will continue to stretch, but now it takes a lot less work. The material is clearly thinning and breaking down. Then, with one last burst of energy, it breaks in half.The maximum stress it could endure immediately before breaking is its Tensile Strength, also known as Ultimate Tensile Strength (UTS) or Ultimate Strength.

What This Means for Pipeline Safety:

Tensile strength has nothing to do with the idea of everyday use. It’s the pipe’s absolute, final line of protection against catastrophic failure. It is a material’s capacity to resist cohesion during a short duration violent event that takes the material far beyond any level of design.

What kind of event? We’re talking about the enormous forces of a major earthquake, a sudden and catastrophic ground subsidence under the pipe, a direct hit from a piece of heavy excavation equipment, or a huge pressure surge (a “water hammer” effect) from a valve slamming shut in a liquid line. Tensile strength is all that separates a badly compromised pipe from a full rupture in these moments.Tensile strength is the raw survivability of the material.

The Gap Between Yield and Tensile Strength is Your True Safety Buffer

Here’s the insight that separates experienced engineers from rookies: the most important number isn’t just the yield strength or the tensile strength alone, but the gap between the two. This gap defines a material’s ductility—its ability to bend and deform before it breaks.

· A brittle material, like cast iron or glass, has a very small gap between its yield and tensile strength. As soon as it’s stressed beyond its elastic limit, it shatters with little to no warning.

· A ductile material, like the steel used in pipelines, is the opposite. It is engineered to have a large, predictable gap between these two strengths.

This is ductile is not a side effect; it is a fundamental design feature. That difference between yielding and breaking is the most important safety buffer in your project. In a high-pressure emergency, a ductile pipe offers a distinct warning: it will start to visibly bow, stretch, and distort far in advance of its bursting. This deformation is a physical signal that the system is under critical stress, providing a valuable window of opportunity for sensors to identify the problem and for operators to take corrective action.

Brittle failure is quiet and instantaneous. Ductile failure is noisy and slow. In pipeline design, we always go with the latter. Engineers know to use this margin explicitly in their safety calculations, so that even in a failure mode the material is still going to fail in the safest possible way.

How are These Properties Reflected in a Product? The API 5L Example

So where do you look to find these important numbers on a spec sheet? They are embedded into the product’s grade, which is established and certified by worldwide standards organizations such as the American Petroleum Institute (API). These bodies are there to make sure that a pipe produced in one country is exactly the same in terms of safety and performance as a pipe produced in another, so you can trust it throughout the global supply chain.

For the globally recognized API 5L standard for line pipe, the code is simple to decipher:

· A pipe graded as API 5L X52 is certified by the manufacturer to have a minimum yield strength of 52,000 pounds per square inch (psi).

· A pipe graded as API 5L X65 is certified to have a minimum yield strength of 65,000 psi.

When you specify a grade from a reputable standard such as API 5L, you are not merely buying a product; you are buying a promise. You are guaranteeing that the physical material delivered to your project site has the exact, certified mechanical properties upon which your engineering team based its safety calculations.

Conclusion

In the end, the physical integrity and safety of your pipeline project depends on a solid grasp of these two separate but interconnected material properties. They are not substitutes, and neither is more important than the other–they are both needed to ensure reliability.

· Yield Strength: This is the boundary for operational integrity. Staying below it ensures the pipeline has a long, predictable service life free from fatigue and permanent damage.

· Tensile Strength: This is the firewall for catastrophic failure. It defines the material’s ultimate ability to hold together when the unexpected happens.

· The Safety Buffer (Ductility): This is the crucial gap between the two strengths. It is an engineered warning system, ensuring that if the operational limit is ever exceeded, the failure is gradual and detectable, not sudden and catastrophic.

Knowing this dynamic lets you ignore the pure numbers on a spec sheet and understand the safety and reliability in the real world that they translate to. It’s the secret to a truly professional and responsible purchasing decision that will age well.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.