HOT PRODUCTS TAGS

Plain end HDPE coupling

·Standard: ANSI / UL 213 ISO

·Material: Ductile iron ASTM A536, 65-45-12

·Bolt & nut: Carbon steel

·Gasket: EPDM, nitrile, silicone rubber, etc

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 2″ – 12″

description

Plain end HDPE couplings are connectors used to connect flat-mouth HDPE pipes, achieving sealed butt joints of flat-mouth pipes through hot-melt, electrofusion or mechanical methods

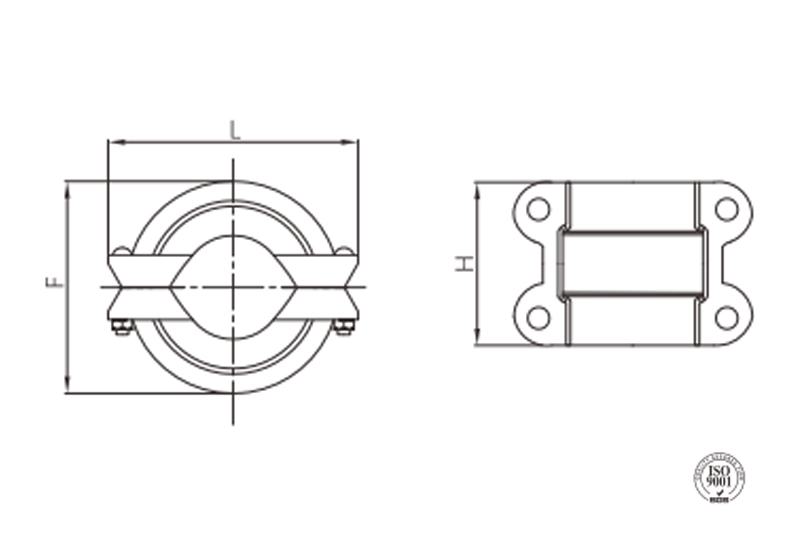

Specification

Available size

Size | Dimension (mm) | Bolting (n x bolt size) | |||||

Inch | DN | mm | F | L | H | ANSI | EN |

2″ | 50 | 60.3 | 83 | 120 | 116 | 4 – 1/2” × 60 | 4 – M12 × 60 |

/ | / | 63.0 | 89 | 116 | 105 | 4 – 3/8” × 55 | 4 – M10 × 55 |

3″ | 80 | 88.9 | 114 | 166 | 118 | 4 – 1/2” × 75 | 4 – M12 × 75 |

/ | / | 110.0 | 137 | 180 | 110 | 4 – 1/2” × 75 | 4 – M12 × 75 |

4″ | 100 | 114.0 | 143 | 201 | 147 | 4 – 1/2” × 75 | 4 – M12 × 75 |

/ | / | 160.0 | 188 | 235 | 118 | 4 – 1/2” × 75 | 4 – M12 × 75 |

6″ | 150 | 168.3 | 202 | 252 | 150 | 4 – 5/8” × 85 | 4 – M16 × 85 |

8″ | 200 | 219.1 | 258 | 320 | 152 | 4 – 5/8” × 85 | 4 – M16 × 85 |

/ | / | 251.5 | 288 | 350 | 141 | 4 – 3/4” × 110 | 4 – M16 × 100 |

10″ | 250 | 273.0 | 313 | 390 | 165 | 4 – 3/4” × 110 | 4 – M20 × 100 |

12″ | 300 | 323.9 | 367 | 455 | 183 | 4 – 3/4” × 120 | 4 – M20 × 120 |

application

- HDPE Plastic Pipe Connections: These are specifically meant for butt-joint HDPE pipes, which makes them perfect for plastic pipe jointing construction projects including water supply and drainage, chemical transportation among others.

- Multi-scenario adaptability: Available for specific installation methods including over-ground exposed or underground buried and supports HDPE pipes of different manufacturers (compatible with standard).

- Medium environments: Heavy chemical, and aggressive waste water pipelines need strong sleeves that guarantee a secure connection.

- In diameter: adapted to most projects, with main pipe diameters ranging between 2 and 12 inches.

advantages

1. Universal Connection: Compatible with three ways of installations hot melting, electrofusion or mechanical connection to suit a wide range of construction conditions.

2. High Sealing and No Leakage: A layered sealing structure guarantees that no water or chemical fluid is leaked at medium to high pressure.

3. Corrosion Resistance Champion:Fully sealed structure features an anti-corrosion surface that resists all models of acid, alkali, and salt corrosion.

4. Flexible Installation: Do not need to have special welding equipment; only bolts are used for mechanical fastening, which is quick and easy in turn reducing the difficulty of construction.

5. Earthquake-resistant and deformation-resistant: a flexible structure can adapt to the uneven settlement or temperature-induced thermal expansion, making the pipe joint not easy to break.

6. Long-Life: Pipeline grade material ensures qualifed lifetime of over 20 years maintenance-free operation.

packing

- Moisture-proof and damage-resistant packaging:

- Each item is individually vacuum-sealed in plastic film, with desiccant included inside, and enclosed in a reinforced corrugated cardboard box (marked: HDPE joint 6 inches).

- Large-size dedicated protection:

- 8 inches and above use custom wooden boxes + impact-resistant corner pads to isolate and protect the flange sealing surface.

- Bulk transportation solution:

- Uniformly stacked on moisture-proof pallets, fully sealed with stretch film, suitable for maritime transport/warehouse humid environments.

Available size

Size | Dimension (mm) | Bolting (n x bolt size) | |||||

Inch | DN | mm | F | L | H | ANSI | EN |

2″ | 50 | 60.3 | 83 | 120 | 116 | 4 – 1/2” × 60 | 4 – M12 × 60 |

/ | / | 63.0 | 89 | 116 | 105 | 4 – 3/8” × 55 | 4 – M10 × 55 |

3″ | 80 | 88.9 | 114 | 166 | 118 | 4 – 1/2” × 75 | 4 – M12 × 75 |

/ | / | 110.0 | 137 | 180 | 110 | 4 – 1/2” × 75 | 4 – M12 × 75 |

4″ | 100 | 114.0 | 143 | 201 | 147 | 4 – 1/2” × 75 | 4 – M12 × 75 |

/ | / | 160.0 | 188 | 235 | 118 | 4 – 1/2” × 75 | 4 – M12 × 75 |

6″ | 150 | 168.3 | 202 | 252 | 150 | 4 – 5/8” × 85 | 4 – M16 × 85 |

8″ | 200 | 219.1 | 258 | 320 | 152 | 4 – 5/8” × 85 | 4 – M16 × 85 |

/ | / | 251.5 | 288 | 350 | 141 | 4 – 3/4” × 110 | 4 – M16 × 100 |

10″ | 250 | 273.0 | 313 | 390 | 165 | 4 – 3/4” × 110 | 4 – M20 × 100 |

12″ | 300 | 323.9 | 367 | 455 | 183 | 4 – 3/4” × 120 | 4 – M20 × 120 |

- HDPE Plastic Pipe Connections: These are specifically meant for butt-joint HDPE pipes, which makes them perfect for plastic pipe jointing construction projects including water supply and drainage, chemical transportation among others.

- Multi-scenario adaptability: Available for specific installation methods including over-ground exposed or underground buried and supports HDPE pipes of different manufacturers (compatible with standard).

- Medium environments: Heavy chemical, and aggressive waste water pipelines need strong sleeves that guarantee a secure connection.

- In diameter: adapted to most projects, with main pipe diameters ranging between 2 and 12 inches.

1. Universal Connection: Compatible with three ways of installations hot melting, electrofusion or mechanical connection to suit a wide range of construction conditions.

2. High Sealing and No Leakage: A layered sealing structure guarantees that no water or chemical fluid is leaked at medium to high pressure.

3. Corrosion Resistance Champion:Fully sealed structure features an anti-corrosion surface that resists all models of acid, alkali, and salt corrosion.

4. Flexible Installation: Do not need to have special welding equipment; only bolts are used for mechanical fastening, which is quick and easy in turn reducing the difficulty of construction.

5. Earthquake-resistant and deformation-resistant: a flexible structure can adapt to the uneven settlement or temperature-induced thermal expansion, making the pipe joint not easy to break.

6. Long-Life: Pipeline grade material ensures qualifed lifetime of over 20 years maintenance-free operation.

- Moisture-proof and damage-resistant packaging:

- Each item is individually vacuum-sealed in plastic film, with desiccant included inside, and enclosed in a reinforced corrugated cardboard box (marked: HDPE joint 6 inches).

- Large-size dedicated protection:

- 8 inches and above use custom wooden boxes + impact-resistant corner pads to isolate and protect the flange sealing surface.

- Bulk transportation solution:

- Uniformly stacked on moisture-proof pallets, fully sealed with stretch film, suitable for maritime transport/warehouse humid environments.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.