HOT PRODUCTS TAGS

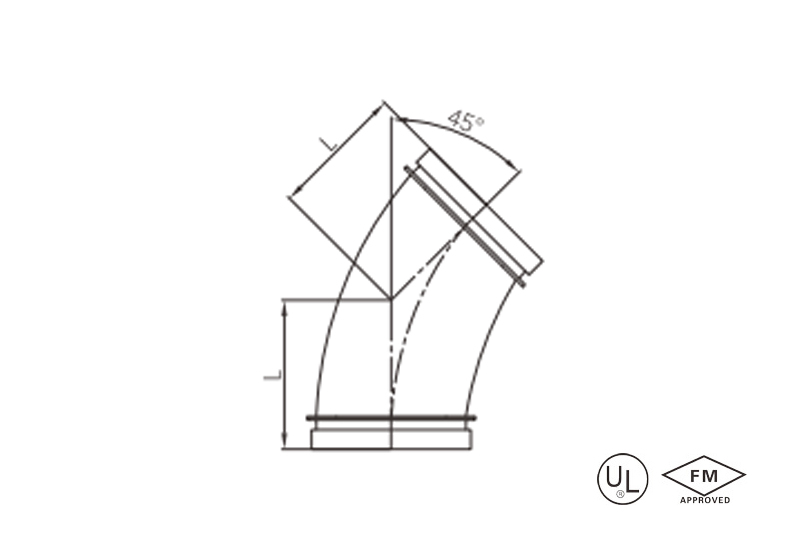

Grooved 45° elbow

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Type: Standard / Long

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 1″ – 24″

description

Grooved 45° elbow is a 45-degree elbow fitting with a grooved connection structure, used to enable the pipeline system to achieve a 45-degree turn

Specification

Available size

| Size | Center to end,L(mm) | |||

| Inch | DN | mm | Standard | Long |

| 1″ | 25 | 33.7 | 45 | / |

| 1-1/4″ | 32 | 42.4 | 45 | / |

| 1-1/2″ | 40 | 48.3 | 45 | / |

| 2″ | 50 | 60.3 | 51 | 70 |

| 2-1/2″ | 65 | 73.0 | 57 | 76 |

| 2-1/2″ | 65 | 76.1 | 57 | / |

| 3″ | 80 | 88.9 | 64 | 86 |

| 4″ | 100 | 114.3 | 76 | 102 |

| 5″ | 125 | 139.7 | 83 | / |

| 5″ | 125 | 141.3 | 83 | / |

| 6″ | 150 | 165.1 | 89 | / |

| 6″ | 150 | 168.3 | 89 | 140 |

| 8″ | 200 | 219.1 | 108 | 184 |

| 10″ | 250 | 273.0 | 121 | 159 |

| 12″ | 300 | 323.9 | 133 | 191 |

| 14″ | 350 | 355.6 | 152 | / |

| 16″ | 400 | 406.4 | 184 | / |

| 18″ | 450 | 457.2 | 203 | / |

| 20″ | 500 | 508 | 229 | / |

| 24″ | 600 | 609.6 | 280 | / |

application

- Smooth flow direction adjustment: Replaces 90° elbows to reduce fluid resistance, suitable for applications requiring smooth turns, such as pump outlets and compressor pipelines.

- Compact space piping layout: In equipment rooms and underground pipe galleries, 45° turns save space and reduce turbulence impact.

- Inclined pipeline systems: Mine conveying pipelines and slope fire protection networks adapt to non-right-angle terrain changes.

- HVAC systems: Reduces turbulence noise in air conditioning chilled water pipelines, improving system energy efficiency.

- High-flow main pipelines: Industrial facilities with large-diameter pipelines (e.g., 12“-24”) above DN300, reducing high-pressure fluid erosion on pipe walls.

advantages

1. Low-flow resistance design: 45° elbow turning 90 °, reducing pressure by about 30%,.saving energy and consumption.

2. Two models to choose from: Standard model: Economical, general turning applications; Expanded model (eg., 2“-12” Configurations): Manufactured with longer bending radius decrease water hammer effect.

3. Short installation time: Installation of groove connections is 80% quicker than flange installations, grooves only require bolt tightening.

4. Ductile iron (ASTjsonmfh4/mn), great strength pressure: withstands 500 psi, very good water biomechanics.

5. Full environmental adaptability: Hot-dip galvanized/red painted coating corrosion protection, suitable for underground humid and chemical plant corrosive environments.

packing

- Graded Protection Plan:

- ≤6 inches: 10 pieces per box, separated by honeycomb cardboard inside, outer box covered with waterproof film;

- >6 inches: Customized wooden box for each piece, lined with EPE foam, reinforced with steel straps at the four corners.

- Damage Prevention Design:

- Silicone strips embedded in grooves and recesses to prevent deformation;

- PE protective film applied to the outer side of the elbow to prevent scratches.

- Smart Identification:

- Outer boxes are spray-printed with arrow indicators for flow direction, with “Extended Type/Long” labels affixed for type classification;

- QR codes link to installation guide videos, which can be scanned to view construction demonstrations.

- Large Item Transportation:

- Bends exceeding 12 inches use framed wooden pallets, with a load limit of 1 piece per pallet;

- Wooden pallets are fitted with anti-slip rubber pads to prevent shifting during transportation.

Available size

| Size | Center to end,L(mm) | |||

| Inch | DN | mm | Standard | Long |

| 1″ | 25 | 33.7 | 45 | / |

| 1-1/4″ | 32 | 42.4 | 45 | / |

| 1-1/2″ | 40 | 48.3 | 45 | / |

| 2″ | 50 | 60.3 | 51 | 70 |

| 2-1/2″ | 65 | 73.0 | 57 | 76 |

| 2-1/2″ | 65 | 76.1 | 57 | / |

| 3″ | 80 | 88.9 | 64 | 86 |

| 4″ | 100 | 114.3 | 76 | 102 |

| 5″ | 125 | 139.7 | 83 | / |

| 5″ | 125 | 141.3 | 83 | / |

| 6″ | 150 | 165.1 | 89 | / |

| 6″ | 150 | 168.3 | 89 | 140 |

| 8″ | 200 | 219.1 | 108 | 184 |

| 10″ | 250 | 273.0 | 121 | 159 |

| 12″ | 300 | 323.9 | 133 | 191 |

| 14″ | 350 | 355.6 | 152 | / |

| 16″ | 400 | 406.4 | 184 | / |

| 18″ | 450 | 457.2 | 203 | / |

| 20″ | 500 | 508 | 229 | / |

| 24″ | 600 | 609.6 | 280 | / |

- Smooth flow direction adjustment: Replaces 90° elbows to reduce fluid resistance, suitable for applications requiring smooth turns, such as pump outlets and compressor pipelines.

- Compact space piping layout: In equipment rooms and underground pipe galleries, 45° turns save space and reduce turbulence impact.

- Inclined pipeline systems: Mine conveying pipelines and slope fire protection networks adapt to non-right-angle terrain changes.

- HVAC systems: Reduces turbulence noise in air conditioning chilled water pipelines, improving system energy efficiency.

- High-flow main pipelines: Industrial facilities with large-diameter pipelines (e.g., 12“-24”) above DN300, reducing high-pressure fluid erosion on pipe walls.

1. Low-flow resistance design: 45° elbow turning 90 °, reducing pressure by about 30%,.saving energy and consumption.

2. Two models to choose from: Standard model: Economical, general turning applications; Expanded model (eg., 2“-12” Configurations): Manufactured with longer bending radius decrease water hammer effect.

3. Short installation time: Installation of groove connections is 80% quicker than flange installations, grooves only require bolt tightening.

4. Ductile iron (ASTjsonmfh4/mn), great strength pressure: withstands 500 psi, very good water biomechanics.

5. Full environmental adaptability: Hot-dip galvanized/red painted coating corrosion protection, suitable for underground humid and chemical plant corrosive environments.

- Graded Protection Plan:

- ≤6 inches: 10 pieces per box, separated by honeycomb cardboard inside, outer box covered with waterproof film;

- >6 inches: Customized wooden box for each piece, lined with EPE foam, reinforced with steel straps at the four corners.

- Damage Prevention Design:

- Silicone strips embedded in grooves and recesses to prevent deformation;

- PE protective film applied to the outer side of the elbow to prevent scratches.

- Smart Identification:

- Outer boxes are spray-printed with arrow indicators for flow direction, with “Extended Type/Long” labels affixed for type classification;

- QR codes link to installation guide videos, which can be scanned to view construction demonstrations.

- Large Item Transportation:

- Bends exceeding 12 inches use framed wooden pallets, with a load limit of 1 piece per pallet;

- Wooden pallets are fitted with anti-slip rubber pads to prevent shifting during transportation.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.