HOT PRODUCTS TAGS

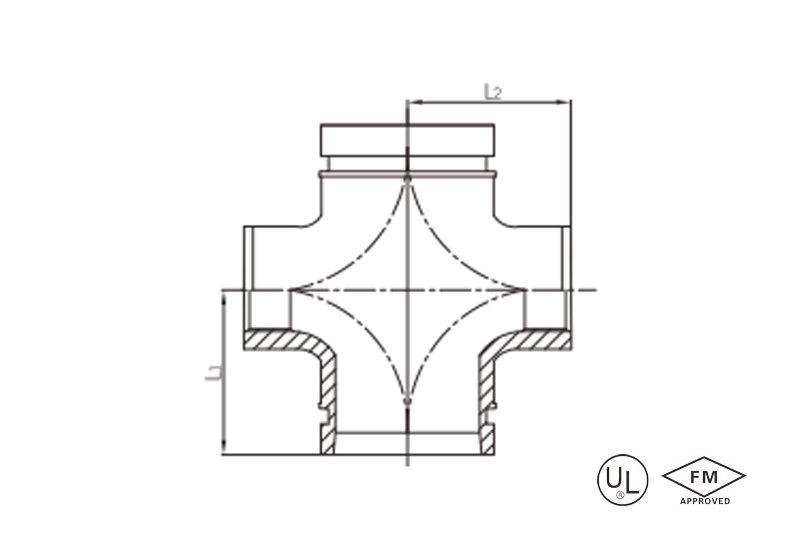

Grooved reducing cross with female threaded branch

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Branch: Female thread, NPT / BSPT

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 2-1/2″×2″ – 6″×3″

description

Grooved reducing cross with female threaded branch is a reducing four-way pipe fitting. The interface with an internal thread design is used for cross-shaped branches of pipes of different diameters and connections of components that require internal thread mating

Specification

Available size

| Size | Center to end(mm) | |||

| Inch | DN | mm | L1 | L2 |

| 2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 76 | 76 |

| 3″ × 1-1/4″ | 80 × 32 | 88.9 × 42.4 | 86 | 86 |

| 3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 86 | 86 |

| 3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 86 | 86 |

| 4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 101 | 101 |

| 4″ × 1-1/4″ | 100 × 32 | 114.3 × 42.4 | 101 | 101 |

| 4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 101 | 101 |

| 4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 101 | 101 |

| 4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 101 | 101 |

| 4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 101 | 101 |

| 6″ × 1-1/4″ | 150 × 32 | 165.1 × 42.4 | 140 | 140 |

| 6″ × 1-1/2″ | 150 × 40 | 165.1 × 48.3 | 140 | 140 |

| 6″ × 2″ | 150 × 50 | 165.1 × 60.3 | 140 | 140 |

| 6″ × 2-1/2″ | 150 × 65 | 165.1 × 76.1 | 140 | 140 |

| 6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 140 | 140 |

application

- Smart Monitoring Hub—A smart monitoring hub exclusively used in industrial system cross-shaped reducer pipe network integrating into instruments or valves, with internal threaded lateral directly linking to pressure gauges, sensors and other interfaces of screw connection devices;

- Compact Type Diversion Retrofit: Applied in conditions known to a chemical plant or power station where space is precious, and it can replace those three -way fittings & reducer pipe combinations with an single component, make pipeline arrangement more straightforward.

- Flexible Expansion of the System: It can be used in expansion projects with multi-directional branching and branch pipe connection for monitoring devices in water treatment, HVAC systems etc.

advantages

1. Integrated multi-functional design: four-way eccentric main pipe for flow distribution; internal threaded branch pipes (NPT/BSPT) are precision matched with the instrumentation equipment without adapter leakage.

2. Sealing performance is high-efficiency: Grooved clamps of seismic resistance / anti-loosening function + Threaded ends with pre-set sealing grooves designs which are suitable for pressure shocks by 300-500 psi.

3. Revolutionary Installation Simplification:Four main pipes with groove clamping in the same plane,threaded branch piping directly screwed into equipment to reduce construction time by 80%.

4. TypeRed Paint/hot-dip galvanized surface treatment, resistant to chemical corrosion and humid environments; long-term protection system for +50 years. Safety and Compliance Listing

5. Certified ANSI/UL/FM : approved for fire protection, steel pipe systems and industrial applications.

packing

- Five-layer interface protection:

- 4 groove ports: covered with PE anti-scratch film + EVA foam corner protectors;

- Internal threaded branch pipes: injected with anti-rust grease + screwed into silicone seal sleeves;

- Crossing points: equipped with biodegradable plastic support frames to prevent deformation.

- Smart layered packaging:

- ≤4″: Single piece placed in a reinforced cardboard box with a custom foam mold, with threaded branch pipes fixed in an upward position;

- >4“: Main body suspended and secured using a ”cross-shaped” wooden frame, then placed in a steel-banded box after being wrapped in moisture-proof aluminum foil bags.

- Error-proofing and traceability system:

- Boxes printed with threaded branch pipe markings ↑ and pressure rating warning labels;

- Includes an independently sealed bag containing installation guidelines (including a threaded adapter chart and QR code-scannable video tutorials).

Available size

| Size | Center to end(mm) | |||

| Inch | DN | mm | L1 | L2 |

| 2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 76 | 76 |

| 3″ × 1-1/4″ | 80 × 32 | 88.9 × 42.4 | 86 | 86 |

| 3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 86 | 86 |

| 3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 86 | 86 |

| 4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 101 | 101 |

| 4″ × 1-1/4″ | 100 × 32 | 114.3 × 42.4 | 101 | 101 |

| 4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 101 | 101 |

| 4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 101 | 101 |

| 4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 101 | 101 |

| 4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 101 | 101 |

| 6″ × 1-1/4″ | 150 × 32 | 165.1 × 42.4 | 140 | 140 |

| 6″ × 1-1/2″ | 150 × 40 | 165.1 × 48.3 | 140 | 140 |

| 6″ × 2″ | 150 × 50 | 165.1 × 60.3 | 140 | 140 |

| 6″ × 2-1/2″ | 150 × 65 | 165.1 × 76.1 | 140 | 140 |

| 6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 140 | 140 |

- Smart Monitoring Hub—A smart monitoring hub exclusively used in industrial system cross-shaped reducer pipe network integrating into instruments or valves, with internal threaded lateral directly linking to pressure gauges, sensors and other interfaces of screw connection devices;

- Compact Type Diversion Retrofit: Applied in conditions known to a chemical plant or power station where space is precious, and it can replace those three -way fittings & reducer pipe combinations with an single component, make pipeline arrangement more straightforward.

- Flexible Expansion of the System: It can be used in expansion projects with multi-directional branching and branch pipe connection for monitoring devices in water treatment, HVAC systems etc.

1. Integrated multi-functional design: four-way eccentric main pipe for flow distribution; internal threaded branch pipes (NPT/BSPT) are precision matched with the instrumentation equipment without adapter leakage.

2. Sealing performance is high-efficiency: Grooved clamps of seismic resistance / anti-loosening function + Threaded ends with pre-set sealing grooves designs which are suitable for pressure shocks by 300-500 psi.

3. Revolutionary Installation Simplification:Four main pipes with groove clamping in the same plane,threaded branch piping directly screwed into equipment to reduce construction time by 80%.

4. TypeRed Paint/hot-dip galvanized surface treatment, resistant to chemical corrosion and humid environments; long-term protection system for +50 years. Safety and Compliance Listing

5. Certified ANSI/UL/FM : approved for fire protection, steel pipe systems and industrial applications.

- Five-layer interface protection:

- 4 groove ports: covered with PE anti-scratch film + EVA foam corner protectors;

- Internal threaded branch pipes: injected with anti-rust grease + screwed into silicone seal sleeves;

- Crossing points: equipped with biodegradable plastic support frames to prevent deformation.

- Smart layered packaging:

- ≤4″: Single piece placed in a reinforced cardboard box with a custom foam mold, with threaded branch pipes fixed in an upward position;

- >4“: Main body suspended and secured using a ”cross-shaped” wooden frame, then placed in a steel-banded box after being wrapped in moisture-proof aluminum foil bags.

- Error-proofing and traceability system:

- Boxes printed with threaded branch pipe markings ↑ and pressure rating warning labels;

- Includes an independently sealed bag containing installation guidelines (including a threaded adapter chart and QR code-scannable video tutorials).

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.