HOT PRODUCTS TAGS

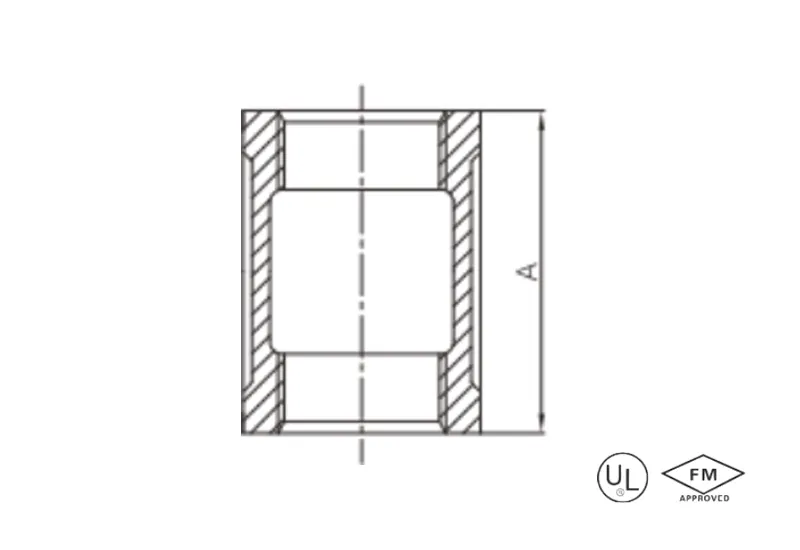

Malleable cast iron socket (Coupling)

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1/4″—6″

description

Malleable cast iron socket, tight connection to prevent leakage, quick installation, corrosion-resistant, pressure-resistant, securing pipelines.

Specification

Available size

SIZE | A | Thread Length | ||

INCH | DN | MM | MM |

|

1/4″ | 8 | 13.5 | 27 | Double ends / Full length |

3/8″ | 10 | 17.2 | 30 | Double ends / Full length |

1/2″ | 15 | 21.3 | 36 | Double ends / Full length |

3/4″ | 20 | 26.9 | 39 | Double ends / Full length |

1″ | 25 | 33.7 | 45 | Double ends / Full length |

1-1/4″ | 32 | 42.4 | 50 | Double ends / Full length |

1-1/2″ | 40 | 48.3 | 55 | Double ends / Full length |

2″ | 50 | 60.3 | 65 | Double ends / Full length |

2-1/2″ | 65 | 76.1 | 74 | Double ends / Full length |

3″ | 80 | 88.9 | 80 | Double ends / Full length |

4″ | 100 | 114.3 | 94 | Double ends / Full length |

6″ | 150 | 165.1 | 105 | Double ends / Full length |

Note: NSF 61 certificate is available for M2301, M2302, M2313.

application

- Chemical Pipeline Repair: Rapidly seal corroded pipeline sections to restore emergency medium transportation.

- Fire Protection System Expansion: UL-certified threaded connections ensure high-pressure, leak-free extension of sprinkler networks.

- Ship Pipeline Maintenance: Rapid replacement and connection of damaged fuel/freshwater pipeline sections in engine rooms.

- Municipal Water Supply Renovation: Threaded direct connection of new and old galvanized steel pipes avoids welding-induced thermal deformation.

- Industrial Equipment Integration: Full-size sealed direct connections for reactor inlet/outlet pipelines.

- Mining Conveyance Network: High-wear-resistant pipe clamps resist vibration-induced loosening in slurry conveyance pipelines.

- Agricultural Irrigation Hub: Segmented rapid maintenance connections for main pipelines at pump stations.

- Energy Pipeline Network Upgrade: Leak-free extension and renovation of 6-inch large-diameter oil and gas pipelines.

advantages

- Dual-end high-pressure sealing: 25 bar operating conditions with BSPT tapered threads ensure zero leakage in both directions.

- NSF safety certification: Drinking water-grade galvanized coating (specific models) eliminates the risk of heavy metal leaching.

- Full Size Coverage: 1/4“ to 6” diameter to meet the needs of micro-instrumentation tubing to main pipelines.

- Armor-Grade Corrosion Resistance: Hot-dip galvanized coating resists 1,200 hours of salt spray corrosion from seawater/chemical media.

- Vibration-Resistant Structural Reinforcement: Thickened wall design improves mechanical impact resistance by 40% compared to standard parts.

- Installation Efficiency Revolution: Dual-threaded direct connection replaces flange assemblies, saving 90% of installation time.

- Wide Temperature Range Reliability: Maintains threaded seal integrity under extreme conditions from -30°C to 120°C.

- Heavy-Duty Diameter Assurance: 6-inch pipe clamps maintain zero deformation under 25 bar pressure.

packing

- Threaded Fortress Protection: Dual-end injection-molded cap nesting + silicone seal ring composite locking.

- Linear Buffering System: EPE pearl cotton molded tubular curved surface full wrap.

- Anti-rust Armor Layer: Vapor-phase anti-rust film + moisture-proof aluminum foil composite vacuum sealing.

- Precision error-proofing structure: Laser-cut pine wood track-style slots precisely fitted to dimensions.

- Heavy-duty load-bearing solution: I-beam steel frame fumigated wooden box (compatible with DN150 load-bearing capacity).

- Anti-rolling design: Inner box H-shaped steel rails locking tube clamps for zero-displacement transportation.

Available size

SIZE | A | Thread Length | ||

INCH | DN | MM | MM |

|

1/4″ | 8 | 13.5 | 27 | Double ends / Full length |

3/8″ | 10 | 17.2 | 30 | Double ends / Full length |

1/2″ | 15 | 21.3 | 36 | Double ends / Full length |

3/4″ | 20 | 26.9 | 39 | Double ends / Full length |

1″ | 25 | 33.7 | 45 | Double ends / Full length |

1-1/4″ | 32 | 42.4 | 50 | Double ends / Full length |

1-1/2″ | 40 | 48.3 | 55 | Double ends / Full length |

2″ | 50 | 60.3 | 65 | Double ends / Full length |

2-1/2″ | 65 | 76.1 | 74 | Double ends / Full length |

3″ | 80 | 88.9 | 80 | Double ends / Full length |

4″ | 100 | 114.3 | 94 | Double ends / Full length |

6″ | 150 | 165.1 | 105 | Double ends / Full length |

Note: NSF 61 certificate is available for M2301, M2302, M2313.

- Chemical Pipeline Repair: Rapidly seal corroded pipeline sections to restore emergency medium transportation.

- Fire Protection System Expansion: UL-certified threaded connections ensure high-pressure, leak-free extension of sprinkler networks.

- Ship Pipeline Maintenance: Rapid replacement and connection of damaged fuel/freshwater pipeline sections in engine rooms.

- Municipal Water Supply Renovation: Threaded direct connection of new and old galvanized steel pipes avoids welding-induced thermal deformation.

- Industrial Equipment Integration: Full-size sealed direct connections for reactor inlet/outlet pipelines.

- Mining Conveyance Network: High-wear-resistant pipe clamps resist vibration-induced loosening in slurry conveyance pipelines.

- Agricultural Irrigation Hub: Segmented rapid maintenance connections for main pipelines at pump stations.

- Energy Pipeline Network Upgrade: Leak-free extension and renovation of 6-inch large-diameter oil and gas pipelines.

- Dual-end high-pressure sealing: 25 bar operating conditions with BSPT tapered threads ensure zero leakage in both directions.

- NSF safety certification: Drinking water-grade galvanized coating (specific models) eliminates the risk of heavy metal leaching.

- Full Size Coverage: 1/4“ to 6” diameter to meet the needs of micro-instrumentation tubing to main pipelines.

- Armor-Grade Corrosion Resistance: Hot-dip galvanized coating resists 1,200 hours of salt spray corrosion from seawater/chemical media.

- Vibration-Resistant Structural Reinforcement: Thickened wall design improves mechanical impact resistance by 40% compared to standard parts.

- Installation Efficiency Revolution: Dual-threaded direct connection replaces flange assemblies, saving 90% of installation time.

- Wide Temperature Range Reliability: Maintains threaded seal integrity under extreme conditions from -30°C to 120°C.

- Heavy-Duty Diameter Assurance: 6-inch pipe clamps maintain zero deformation under 25 bar pressure.

- Threaded Fortress Protection: Dual-end injection-molded cap nesting + silicone seal ring composite locking.

- Linear Buffering System: EPE pearl cotton molded tubular curved surface full wrap.

- Anti-rust Armor Layer: Vapor-phase anti-rust film + moisture-proof aluminum foil composite vacuum sealing.

- Precision error-proofing structure: Laser-cut pine wood track-style slots precisely fitted to dimensions.

- Heavy-duty load-bearing solution: I-beam steel frame fumigated wooden box (compatible with DN150 load-bearing capacity).

- Anti-rolling design: Inner box H-shaped steel rails locking tube clamps for zero-displacement transportation.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.