HOT PRODUCTS TAGS

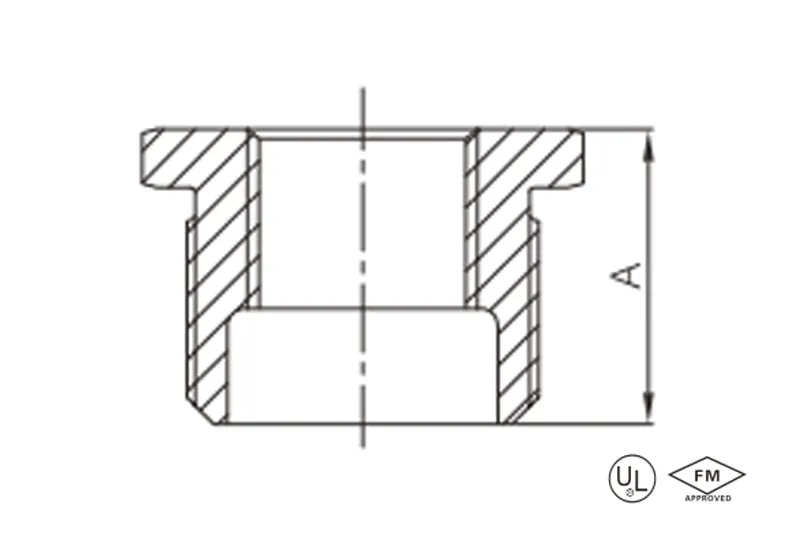

Malleable iron hexagon head bushing (Outside head)

·Standard: ASME B16.14

UL/FM

·Material: Malleable iron ASTM A197

·Thread: NPT

·W. pressure: Class 150, 300 psi (-29°C to 66°C)

·Surface: Black iron / hot dip galvanized

·Size Range: 3/8” x 1/4”—2″ x 1-1/2″ (Class 150)

description

Malleable iron hexagon head bushing (Outside head) features easy installation via hex design, precise threading, with pressure & corrosion resistance.

Specification

Available size

SIZE | A(min) | ||

INCH | DN | MM | MM |

1/2″ x 1/8″ | 15 x 6 | 21.3 x 10.3 | 19 |

1/2″ x 1/4″ | 15 x 8 | 21.3 x 13.7 | 19 |

1/2″ x 3/8″ | 15 x 10 | 21.3 x 17.1 | 19 |

3/4″ x 1/8″ | 20 x 6 | 26.7 x 10.2 | 21.6 |

3/4″ x 1/4″ | 20 x 8 | 26.7 x 13.7 | 21.6 |

3/4″ x 3/8″ | 20 x 10 | 26.7 x 17.1 | 21.6 |

3/4″ x 1/2″ | 20 x 15 | 26.7 x 21.3 | 21.6 |

1″ x 1/2″ | 25 x 15 | 33.4 x 21.3 | 25.5 |

1″ x 3/4″ | 25 x 20 | 33.4 x 26.7 | 25.5 |

1-1/4″ x 3/4″ | 32 x 20 | 42.2 x 26.7 | 27.4 |

1-1/4″ x 1″ | 32 x 25 | 42.2 x 33.4 | 27.4 |

1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.4 | 29 |

1-1/2″ x 1-1/4″ | 40 x 32 | 48.3 x 42.2 | 29 |

2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.2 | 31 |

2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 31 |

2-1/2″ x 1-1/2″ | 65 x 40 | 73.0 x 48.3 | 36.6 |

2-1/2″ x 2″ | 65 x 50 | 73.0 x 60.3 | 36.6 |

3″ x 2″ | 80 x 50 | 88.9 x 60.3 | 40.9 |

3″ x 2-1/2″ | 80 x 65 | 88.9 x 73.0 | 40.9 |

4″ x 3″ | 100 x 80 | 114.3 x 88.9 | 43.7 |

application

- Equipment Port Specification Conversion: Transition between large-threaded ports on industrial equipment and small-diameter pipes.

- Instrument Measurement Pipeline Installation: Transition between pressure gauges/sensors and main pipelines.

- Water Treatment System Renovation: Transition between filtration equipment and water supply pipelines.

- Ship Equipment Interface Adaptation: Hexagonal quick-connect between engine room equipment and deck pipelines.

- Agricultural irrigation system upgrades: Efficient diameter conversion connections between pump house equipment and field pipelines.

- Laboratory precision piping: Reliable diameter transition between instrumentation equipment and micro-pipelines.

- Energy station valve group connections: Pressure-resistant diameter conversion between control valve groups and conveying pipelines.

- Fire protection equipment rapid maintenance: Emergency diameter conversion connections between fire hydrants and temporary water supply pipelines.

advantages

- Hexagonal quick installation: The external hexagonal design supports quick tightening and removal with a wrench.

- Dual-direction diameter adaptation: Flexibly connects two different pipe end specifications.

- High-pressure dynamic sealing: Maintains long-term zero leakage at the interface under extreme conditions.

- Full Environmental Corrosion Resistance: Thickened galvanized coating resists chemical medium corrosion.

- Wide Size Coverage: Fully compatible with micro-precision tubes to large industrial tubes.

- Thermal Deformation Resistance Structure: Maintains threaded connection stability under temperature changes.

- Vibration-Resistant Loosening Design: Special thread locking mechanism prevents interface displacement.

- Lifetime Maintenance-Free Commitment: Optimized processes significantly extend service life.

packing

- Hexagonal head protective sleeve: Custom PE protective cover wraps around the external hexagonal head to prevent impact damage.

- Double protection for threaded ends: Screw cap + foam ring composite protection for internal and external threads.

- Scratch-resistant full coverage: Bubble column bag completely covers the surface of the tube.

- Intelligent specification positioning: Honeycomb cardboard compartments are classified and fixed according to size.

- Dual-color diameter marking: Outer box with dual-color printing corresponding to variable diameter specifications.

- Load-bearing grading scheme: Small-sized paper boxes/large-sized reinforced wooden boxes for separate packaging.

- Full-process traceability system: Laser engraving + smart QR code dual traceability.

Available size

SIZE | A(min) | ||

INCH | DN | MM | MM |

1/2″ x 1/8″ | 15 x 6 | 21.3 x 10.3 | 19 |

1/2″ x 1/4″ | 15 x 8 | 21.3 x 13.7 | 19 |

1/2″ x 3/8″ | 15 x 10 | 21.3 x 17.1 | 19 |

3/4″ x 1/8″ | 20 x 6 | 26.7 x 10.2 | 21.6 |

3/4″ x 1/4″ | 20 x 8 | 26.7 x 13.7 | 21.6 |

3/4″ x 3/8″ | 20 x 10 | 26.7 x 17.1 | 21.6 |

3/4″ x 1/2″ | 20 x 15 | 26.7 x 21.3 | 21.6 |

1″ x 1/2″ | 25 x 15 | 33.4 x 21.3 | 25.5 |

1″ x 3/4″ | 25 x 20 | 33.4 x 26.7 | 25.5 |

1-1/4″ x 3/4″ | 32 x 20 | 42.2 x 26.7 | 27.4 |

1-1/4″ x 1″ | 32 x 25 | 42.2 x 33.4 | 27.4 |

1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.4 | 29 |

1-1/2″ x 1-1/4″ | 40 x 32 | 48.3 x 42.2 | 29 |

2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.2 | 31 |

2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 31 |

2-1/2″ x 1-1/2″ | 65 x 40 | 73.0 x 48.3 | 36.6 |

2-1/2″ x 2″ | 65 x 50 | 73.0 x 60.3 | 36.6 |

3″ x 2″ | 80 x 50 | 88.9 x 60.3 | 40.9 |

3″ x 2-1/2″ | 80 x 65 | 88.9 x 73.0 | 40.9 |

4″ x 3″ | 100 x 80 | 114.3 x 88.9 | 43.7 |

- Equipment Port Specification Conversion: Transition between large-threaded ports on industrial equipment and small-diameter pipes.

- Instrument Measurement Pipeline Installation: Transition between pressure gauges/sensors and main pipelines.

- Water Treatment System Renovation: Transition between filtration equipment and water supply pipelines.

- Ship Equipment Interface Adaptation: Hexagonal quick-connect between engine room equipment and deck pipelines.

- Agricultural irrigation system upgrades: Efficient diameter conversion connections between pump house equipment and field pipelines.

- Laboratory precision piping: Reliable diameter transition between instrumentation equipment and micro-pipelines.

- Energy station valve group connections: Pressure-resistant diameter conversion between control valve groups and conveying pipelines.

- Fire protection equipment rapid maintenance: Emergency diameter conversion connections between fire hydrants and temporary water supply pipelines.

- Hexagonal quick installation: The external hexagonal design supports quick tightening and removal with a wrench.

- Dual-direction diameter adaptation: Flexibly connects two different pipe end specifications.

- High-pressure dynamic sealing: Maintains long-term zero leakage at the interface under extreme conditions.

- Full Environmental Corrosion Resistance: Thickened galvanized coating resists chemical medium corrosion.

- Wide Size Coverage: Fully compatible with micro-precision tubes to large industrial tubes.

- Thermal Deformation Resistance Structure: Maintains threaded connection stability under temperature changes.

- Vibration-Resistant Loosening Design: Special thread locking mechanism prevents interface displacement.

- Lifetime Maintenance-Free Commitment: Optimized processes significantly extend service life.

- Hexagonal head protective sleeve: Custom PE protective cover wraps around the external hexagonal head to prevent impact damage.

- Double protection for threaded ends: Screw cap + foam ring composite protection for internal and external threads.

- Scratch-resistant full coverage: Bubble column bag completely covers the surface of the tube.

- Intelligent specification positioning: Honeycomb cardboard compartments are classified and fixed according to size.

- Dual-color diameter marking: Outer box with dual-color printing corresponding to variable diameter specifications.

- Load-bearing grading scheme: Small-sized paper boxes/large-sized reinforced wooden boxes for separate packaging.

- Full-process traceability system: Laser engraving + smart QR code dual traceability.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.