HOT PRODUCTS TAGS

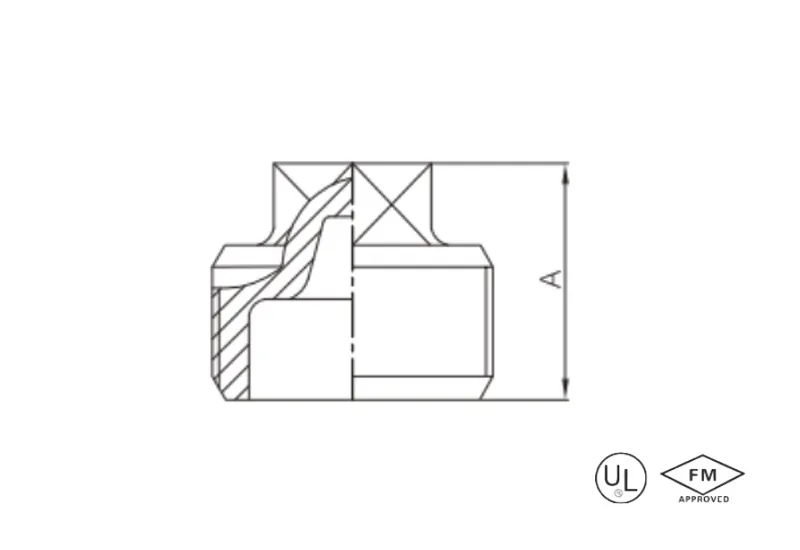

Malleable cast iron plain plug

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1/4″ —6″

description

Malleable cast iron plain plug, seamlessly blocks pipelines, wear-resistant and corrosion-resistant, smooth surface for easy cleaning.

Specification

Available size

SIZE | A(min) | ||

INCH | DN | MM | MM |

1/4″ | 8 | 13.5 | 14 |

3/8″ | 10 | 17.2 | 15 |

1/2″ | 15 | 21.3 | 18 |

3/4″ | 20 | 26.9 | 20 |

1″ | 25 | 33.7 | 23 |

1-1/4″ | 32 | 42.4 | 29 |

1-1/2″ | 40 | 48.3 | 30 |

2″ | 50 | 60.3 | 36 |

2-1/2″ | 65 | 76.1 | 39 |

3″ | 80 | 88.9 | 44 |

4″ | 100 | 114.3 | 58 |

6″ | 150 | 165.1 | 71.5 |

Note: NSF 61 certificate is available for M3501 ~ M3511, except M3513.

application

- Pipe system terminal sealing: Providing permanent closed protection for the end of fire sprinkler networks.

- Industrial equipment interface management: Sealing solutions for reserved openings in compressor/reactor process pipes.

- Ship pipe terminal protection: Anti-corrosion sealing for fuel/cooling water pipe ports in engine rooms.

- Municipal pipeline renovation projects: Sealing solutions to prevent foreign object intrusion at the ends of branch pipelines from main roads.

- Energy transmission system protection: Long-term dust and moisture-proof solutions for oil and gas pipeline interfaces.

- Agricultural irrigation network terminals: Sealing components to prevent silt accumulation at pump station outlet ports.

- Chemical process equipment protection: Chemically resistant sealing solutions for pipeline ports exposed to corrosive media.

- Mining pipeline system maintenance: Protective sealing solutions for pipeline ports in high-wear environments.

advantages

- Flat seal design: With smooth end faces, assures dead angle-free inside sealing at the pipe ends.

- Sealing performance under high pressure: The tapered thread has an industrial pipe end specific stress requirement.

- Easy to clean surface: polished finish so that media does not adhere and integral seat allows easy maintenance and cleaning.

- Durable corrosion protection: Full-body hot-dip galvanizing process provides complete corrosion protection.

- Easy to install and save time: Common tools quick installation and disassemble.

- Certification assurance: Some models are in compliance with Drinking Water Contact Material standards .

packing

- End face protection system: PE cushion pads are applied to the sealing surface to prevent scratches.

- Thread protection solution: Engineering plastic screw caps are used to protect the thread structure.

- Anti-corrosion treatment process: Vacuum-sealed packaging with vapor phase corrosion inhibitor anti-corrosion film.

- Unitized transportation solution: High-strength corrugated boxes with layered positioning packaging.

- Traceability information integration: Box QR code association certification and specification parameters.

- Corner protection design: Reinforced corner protectors inside the box to prevent transportation collision damage.

Available size

SIZE | A(min) | ||

INCH | DN | MM | MM |

1/4″ | 8 | 13.5 | 14 |

3/8″ | 10 | 17.2 | 15 |

1/2″ | 15 | 21.3 | 18 |

3/4″ | 20 | 26.9 | 20 |

1″ | 25 | 33.7 | 23 |

1-1/4″ | 32 | 42.4 | 29 |

1-1/2″ | 40 | 48.3 | 30 |

2″ | 50 | 60.3 | 36 |

2-1/2″ | 65 | 76.1 | 39 |

3″ | 80 | 88.9 | 44 |

4″ | 100 | 114.3 | 58 |

6″ | 150 | 165.1 | 71.5 |

Note: NSF 61 certificate is available for M3501 ~ M3511, except M3513.

- Pipe system terminal sealing: Providing permanent closed protection for the end of fire sprinkler networks.

- Industrial equipment interface management: Sealing solutions for reserved openings in compressor/reactor process pipes.

- Ship pipe terminal protection: Anti-corrosion sealing for fuel/cooling water pipe ports in engine rooms.

- Municipal pipeline renovation projects: Sealing solutions to prevent foreign object intrusion at the ends of branch pipelines from main roads.

- Energy transmission system protection: Long-term dust and moisture-proof solutions for oil and gas pipeline interfaces.

- Agricultural irrigation network terminals: Sealing components to prevent silt accumulation at pump station outlet ports.

- Chemical process equipment protection: Chemically resistant sealing solutions for pipeline ports exposed to corrosive media.

- Mining pipeline system maintenance: Protective sealing solutions for pipeline ports in high-wear environments.

- Flat seal design: With smooth end faces, assures dead angle-free inside sealing at the pipe ends.

- Sealing performance under high pressure: The tapered thread has an industrial pipe end specific stress requirement.

- Easy to clean surface: polished finish so that media does not adhere and integral seat allows easy maintenance and cleaning.

- Durable corrosion protection: Full-body hot-dip galvanizing process provides complete corrosion protection.

- Easy to install and save time: Common tools quick installation and disassemble.

- Certification assurance: Some models are in compliance with Drinking Water Contact Material standards .

- End face protection system: PE cushion pads are applied to the sealing surface to prevent scratches.

- Thread protection solution: Engineering plastic screw caps are used to protect the thread structure.

- Anti-corrosion treatment process: Vacuum-sealed packaging with vapor phase corrosion inhibitor anti-corrosion film.

- Unitized transportation solution: High-strength corrugated boxes with layered positioning packaging.

- Traceability information integration: Box QR code association certification and specification parameters.

- Corner protection design: Reinforced corner protectors inside the box to prevent transportation collision damage.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.