HOT PRODUCTS TAGS

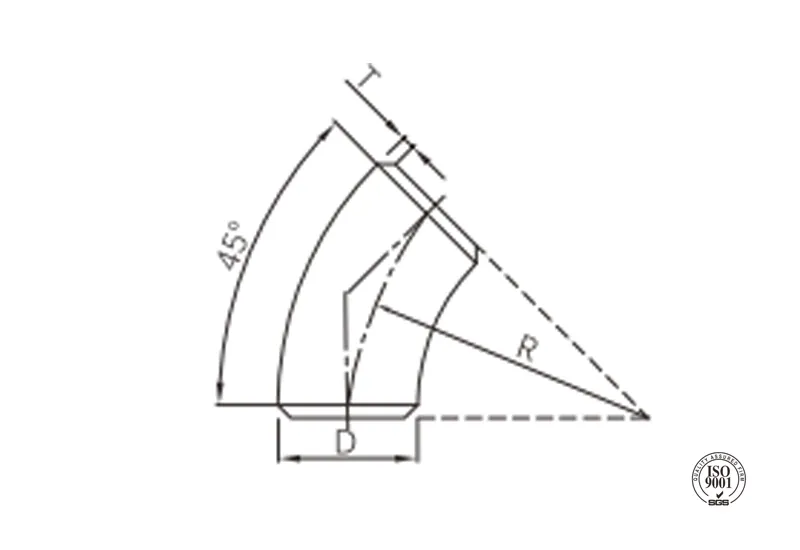

Butt weld 45° elbow (Long radius)

·Standard: ISO

EN 10253-1 / EN 10253-2 / EN 10253-3

·Material: Carbon steel S235 / P235TR2

SS equivalent to WP304 / WP316L

·Type: Long radius, 3D, R=1.5D

·W. pressure: Equal to same straight pipe

·Surface: Black painting / hot dip galvanized

Pickling white, etc.

·Size range: 1″-24″

description

butt weld 45 ° elbow (long radius) for smooth flow with low resistance, combined with butt weld connections to ensure high sealing and structural strength, significantly reducing energy consumption and maintenance costs.

Specification

Available size

| Size | Preferred T to EN 10253-2(mm) | R(mm) | ||

| NPS | DN | OD(mm) | ||

| 1/2″ | 15 | 21.3 | 2.0/2.6/3.214.0/5.0/7.1 | 38 |

| 3/4″ | 20 | 26.9 | 2.3/2.6/3.214.014.515.6/8.0 | 38 |

| 1″ | 25 | 33.7 | 2.6/3.214.0/4.5/5.6/6.3/8.8 | 38 |

| 1-1/4″ | 32 | 42.4 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 48 |

| 1-1/2″ | 40 | 48.3 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 57 |

| 2″ | 50 | 60.3 | 2.9/3.6/4.0/5.6/7.1/8.8/11.0 | 76 |

| 2-1/2″ | 65 | 76.1 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 95 |

| 3″ | 80 | 88.9 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 114 |

| 4″ | 100 | 114.3 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 152 |

| 5″ | 125 | 139.7 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 190 |

| 6″ | 150 | 165.1/168.3 | 4.0/4.5/5.617.1/11.0/14.2/17.5122.2 | 229 |

| 8″ | 200 | 219.1 | 4.5/6.3/7.1/8.0/12.5/16.0/17.5/22.2 | 305 |

| 10″ | 250 | 273.0 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 381 |

| 12″ | 300 | 323.9 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 457 |

| 14″ | 350 | 355.6 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 533 |

| 16″ | 400 | 406.4 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 610 |

| 18″ | 450 | 457 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0145.0 | 686 |

| 20″ | 500 | 508 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 762 |

| 24″ | 600 | 610 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 914 |

application

- Used in pipeline systems where a smooth change in fluid direction (45°) is required, ensuring low flow resistance and minimizing turbulence.

- Suitable for systems that emphasize energy efficiency, such as HVAC, water supply systems, chemical processes, and low-pressure steam pipelines.

- Ideal for applications where reducing the impact of flow resistance on system efficiency is critical.

advantages

- Fluid Optimization Design: Long radius structure (R=1.5D) achieves smooth flow, significantly reducing turbulence, pressure drop, and energy loss.

- High Sealing Connection: Provides excellent sealing and structural strength for welded joints, suitable for high integrity piping systems.

- Corrosion-Resistant Materials: Offers carbon steel (S235/P235TR2) and stainless steel (WP304/WP316L equivalent) options, suitable for corrosive/clean environments.

- Low maintenance costs: Smooth fluid characteristics extend system lifespan and reduce maintenance requirements.

- Surface protection processes: Supports black coating, hot-dip galvanizing, or acid washing and whitening treatments to enhance durability.

- Pressure reliability: Pressure-bearing capacity is consistent with that of straight pipe sections of the same specification.

- Wide compatibility: Covers standard industrial pipe sizes from 1 inch to 24 inches (NPS).

packing

- Export Standard Reinforcement Packaging: Carried in wooden cases or restraint boxes to prevent damage due to collision.

- Small-size packaging- Thickened carton boxes with internal filler materials.

- Protective measures:Plastic caps/plugs are installed on pipe openings, and the surface is wrapped in rust-proof oil paper.

- Clear labeling:Label with product name, dimensions, material, quantity, and warning labels (e.g., “Fragile,” “Keep Dry”).

Available size

| Size | Preferred T to EN 10253-2(mm) | R(mm) | ||

| NPS | DN | OD(mm) | ||

| 1/2″ | 15 | 21.3 | 2.0/2.6/3.214.0/5.0/7.1 | 38 |

| 3/4″ | 20 | 26.9 | 2.3/2.6/3.214.014.515.6/8.0 | 38 |

| 1″ | 25 | 33.7 | 2.6/3.214.0/4.5/5.6/6.3/8.8 | 38 |

| 1-1/4″ | 32 | 42.4 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 48 |

| 1-1/2″ | 40 | 48.3 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 57 |

| 2″ | 50 | 60.3 | 2.9/3.6/4.0/5.6/7.1/8.8/11.0 | 76 |

| 2-1/2″ | 65 | 76.1 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 95 |

| 3″ | 80 | 88.9 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 114 |

| 4″ | 100 | 114.3 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 152 |

| 5″ | 125 | 139.7 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 190 |

| 6″ | 150 | 165.1/168.3 | 4.0/4.5/5.617.1/11.0/14.2/17.5122.2 | 229 |

| 8″ | 200 | 219.1 | 4.5/6.3/7.1/8.0/12.5/16.0/17.5/22.2 | 305 |

| 10″ | 250 | 273.0 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 381 |

| 12″ | 300 | 323.9 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 457 |

| 14″ | 350 | 355.6 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 533 |

| 16″ | 400 | 406.4 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 610 |

| 18″ | 450 | 457 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0145.0 | 686 |

| 20″ | 500 | 508 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 762 |

| 24″ | 600 | 610 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 914 |

- Used in pipeline systems where a smooth change in fluid direction (45°) is required, ensuring low flow resistance and minimizing turbulence.

- Suitable for systems that emphasize energy efficiency, such as HVAC, water supply systems, chemical processes, and low-pressure steam pipelines.

- Ideal for applications where reducing the impact of flow resistance on system efficiency is critical.

- Fluid Optimization Design: Long radius structure (R=1.5D) achieves smooth flow, significantly reducing turbulence, pressure drop, and energy loss.

- High Sealing Connection: Provides excellent sealing and structural strength for welded joints, suitable for high integrity piping systems.

- Corrosion-Resistant Materials: Offers carbon steel (S235/P235TR2) and stainless steel (WP304/WP316L equivalent) options, suitable for corrosive/clean environments.

- Low maintenance costs: Smooth fluid characteristics extend system lifespan and reduce maintenance requirements.

- Surface protection processes: Supports black coating, hot-dip galvanizing, or acid washing and whitening treatments to enhance durability.

- Pressure reliability: Pressure-bearing capacity is consistent with that of straight pipe sections of the same specification.

- Wide compatibility: Covers standard industrial pipe sizes from 1 inch to 24 inches (NPS).

- Export Standard Reinforcement Packaging: Carried in wooden cases or restraint boxes to prevent damage due to collision.

- Small-size packaging- Thickened carton boxes with internal filler materials.

- Protective measures:Plastic caps/plugs are installed on pipe openings, and the surface is wrapped in rust-proof oil paper.

- Clear labeling:Label with product name, dimensions, material, quantity, and warning labels (e.g., “Fragile,” “Keep Dry”).

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.