HOT PRODUCTS TAGS

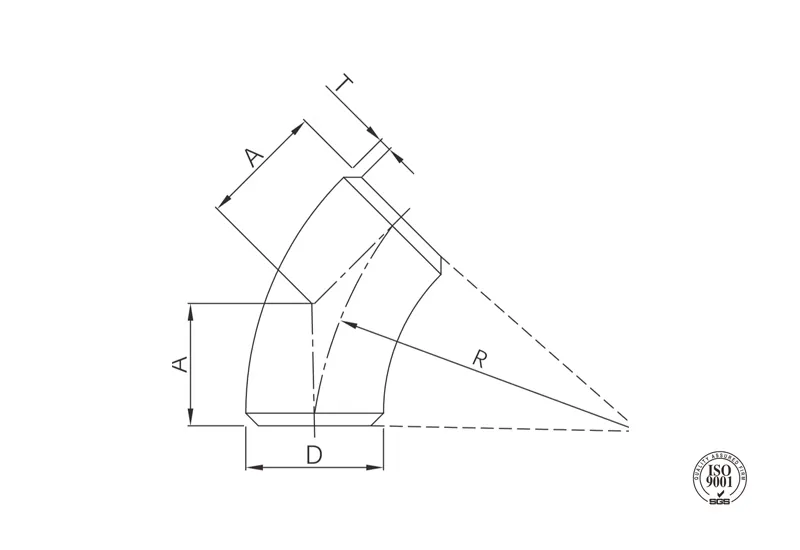

Butt weld 45° elbow (Long radius)

·Standard: ISO

ASME B16.9

·Material: Carbon steel ASTM A234, WPB

SS ASTM A403, WP304 / WP316L

·Type: Long radius, R=1.5D

·W. pressure: Equal to same seamless pipe

·Surface: Black painting / hot dip galvanized Pickling white, etc.

·Size range: 1″-24″

description

butt welding 45 ° elbow (long radius) is used to connect two pipes by butt welding, so that the pipe changes 45 degrees to change the direction of fluid flow, significantly reducing fluid resistance and optimizing piping system efficiency.

Specification

Available size

| Size | Tnickness (mm) | A(mm) | ||||

| NPS | DN | OD(mm) | Sch10 | Sch40 | Sch80 | |

| 1/2″ | 15 | 21.3 | 2.11 | 2.77 | 3.73 | 16 |

| 3/4″ | 20 | 26.7 | 2.11 | 2.87 | 3.91 | 19 |

| 1″ | 25 | 33.4 | 2.77 | 3.38 | 4.55 | 22 |

| 1-1/4″ | 32 | 42.2 | 2.77 | 3.56 | 4.85 | 25 |

| 1-1/2″ | 40 | 48.3 | 2.77 | 3.68 | 5.08 | 29 |

| 2″ | 50 | 60.3 | 2.77 | 3.91 | 5.54 | 35 |

| 2-1/2″ | 65 | 73.0 | 3.05 | 5.16 | 7.01 | 44 |

| 3″ | 80 | 88.9 | 3.05 | 5.49 | 7.62 | 51 |

| 4″ | 100 | 114.3 | 3.05 | 6.02 | 8.56 | 64 |

| 5″ | 125 | 141.3 | 3.40 | 6.55 | 9.53 | 79 |

| 6″ | 150 | 168.3 | 3.40 | 7.11 | 10.97 | 95 |

| 8″ | 200 | 219.1 | 3.76 | 8.18 | 12.70 | 127 |

| 10″ | 250 | 273.0 | 4.19 | 9.27 | 15.09 | 159 |

| 12″ | 300 | 323.8 | 4.57 | 10.31 | 17.48 | 190 |

| 14″ | 350 | 355.6 | 6.35 | 11.13 | 19.05 | 222 |

| 16″ | 400 | 406.4 | 6.35 | 12.70 | 21.44 | 254 |

| 18″ | 450 | 457 | 6.35 | 14.27 | 23.83 | 286 |

| 20″ | 500 | 508 | 6.35 | 15.09 | 26.19 | 318 |

| 24″ | 600 | 610 | 6.35 | 17.48 | 30.96 | 381 |

Note: The thickness is available with Sch5, Sch10, Sch30, Sch40, Sch80, Sch120, Sch160, STD, XS, XXS, 5S, 10S, 40S, 80S, etc.

application

- Gentle fluid diversion: Specifically designed for pipeline systems that require a smooth change in flow direction, such as pump inlets and outlets, and air conditioning circulation pipes, to reduce fluid impact damage to equipment.

- High-efficiency energy-saving system: Suitable for long-distance transmission pipelines (such as chemical and HVAC systems), reducing pressure loss at elbows and improving energy utilization efficiency.

- Rugged Environment Compatibility: Available in carbon steel or stainless steel versions, suitable for high-cleanliness environments like food factories and pharmaceutical facilities, as well as corrosive environments like coastal areas and chemical plants.

- Full Size Compatibility: Covers pipes from ½ inch to 24 inches (DN15-DN600), seamlessly connecting from small instruments to industrial main pipelines.

advantages

- Fluid Zero ImpactDesign: Long radius bends create a gentle flow path system wide — protecting pumps and valves while reducing erosion, vibration, and wear throughout the entire system.

- Rust And Chemical Corrosion Resistance: Hot-dip galvanized or pickled (polished surface) base material + metal coating ensures over 20 years durability in underground or humid environment.

- Full sealing safety: The butt-welded joint is welded with the pipeline and will not leak in any case, so that dangerous media can be safely transported.

- One Time Welding Foreveer Strength: It can be done by welding over the life of product without loosening and Maitenance free which high long time maintenance cost.

- Universal Standard Compliance: ISO/ASTM International standards and compatible with any mainstream pipeline system, avoiding the expense of customization. Extreme condition resistance: The pressure and temperature resistance can match the pipeline characteristics, which are good for steam or hot oil services where it involves high-temperature, high-pressure applications .

packing

- Triple protective packaging:

- Each item is wrapped in anti-rust film + foam corner protectors and placed in a thickened cardboard box (marked: 45° long elbow, 6 inches).

- Stainless steel products are equipped with an additional scratch-resistant pearl cotton layer.

- Large-size custom solutions:

- For 8 inches and above, an arched wooden support frame is used, with custom foam inserts to secure the curved surfaces of the elbows, preventing deformation during transportation.

- Smart maritime loading:

- Small-sized items are nested together, while large-sized items are placed on individual pallets, increasing container space utilization by 35%.

Available size

| Size | Tnickness (mm) | A(mm) | ||||

| NPS | DN | OD(mm) | Sch10 | Sch40 | Sch80 | |

| 1/2″ | 15 | 21.3 | 2.11 | 2.77 | 3.73 | 16 |

| 3/4″ | 20 | 26.7 | 2.11 | 2.87 | 3.91 | 19 |

| 1″ | 25 | 33.4 | 2.77 | 3.38 | 4.55 | 22 |

| 1-1/4″ | 32 | 42.2 | 2.77 | 3.56 | 4.85 | 25 |

| 1-1/2″ | 40 | 48.3 | 2.77 | 3.68 | 5.08 | 29 |

| 2″ | 50 | 60.3 | 2.77 | 3.91 | 5.54 | 35 |

| 2-1/2″ | 65 | 73.0 | 3.05 | 5.16 | 7.01 | 44 |

| 3″ | 80 | 88.9 | 3.05 | 5.49 | 7.62 | 51 |

| 4″ | 100 | 114.3 | 3.05 | 6.02 | 8.56 | 64 |

| 5″ | 125 | 141.3 | 3.40 | 6.55 | 9.53 | 79 |

| 6″ | 150 | 168.3 | 3.40 | 7.11 | 10.97 | 95 |

| 8″ | 200 | 219.1 | 3.76 | 8.18 | 12.70 | 127 |

| 10″ | 250 | 273.0 | 4.19 | 9.27 | 15.09 | 159 |

| 12″ | 300 | 323.8 | 4.57 | 10.31 | 17.48 | 190 |

| 14″ | 350 | 355.6 | 6.35 | 11.13 | 19.05 | 222 |

| 16″ | 400 | 406.4 | 6.35 | 12.70 | 21.44 | 254 |

| 18″ | 450 | 457 | 6.35 | 14.27 | 23.83 | 286 |

| 20″ | 500 | 508 | 6.35 | 15.09 | 26.19 | 318 |

| 24″ | 600 | 610 | 6.35 | 17.48 | 30.96 | 381 |

Note: The thickness is available with Sch5, Sch10, Sch30, Sch40, Sch80, Sch120, Sch160, STD, XS, XXS, 5S, 10S, 40S, 80S, etc.

- Gentle fluid diversion: Specifically designed for pipeline systems that require a smooth change in flow direction, such as pump inlets and outlets, and air conditioning circulation pipes, to reduce fluid impact damage to equipment.

- High-efficiency energy-saving system: Suitable for long-distance transmission pipelines (such as chemical and HVAC systems), reducing pressure loss at elbows and improving energy utilization efficiency.

- Rugged Environment Compatibility: Available in carbon steel or stainless steel versions, suitable for high-cleanliness environments like food factories and pharmaceutical facilities, as well as corrosive environments like coastal areas and chemical plants.

- Full Size Compatibility: Covers pipes from ½ inch to 24 inches (DN15-DN600), seamlessly connecting from small instruments to industrial main pipelines.

- Fluid Zero ImpactDesign: Long radius bends create a gentle flow path system wide — protecting pumps and valves while reducing erosion, vibration, and wear throughout the entire system.

- Rust And Chemical Corrosion Resistance: Hot-dip galvanized or pickled (polished surface) base material + metal coating ensures over 20 years durability in underground or humid environment.

- Full sealing safety: The butt-welded joint is welded with the pipeline and will not leak in any case, so that dangerous media can be safely transported.

- One Time Welding Foreveer Strength: It can be done by welding over the life of product without loosening and Maitenance free which high long time maintenance cost.

- Universal Standard Compliance: ISO/ASTM International standards and compatible with any mainstream pipeline system, avoiding the expense of customization. Extreme condition resistance: The pressure and temperature resistance can match the pipeline characteristics, which are good for steam or hot oil services where it involves high-temperature, high-pressure applications .

- Triple protective packaging:

- Each item is wrapped in anti-rust film + foam corner protectors and placed in a thickened cardboard box (marked: 45° long elbow, 6 inches).

- Stainless steel products are equipped with an additional scratch-resistant pearl cotton layer.

- Large-size custom solutions:

- For 8 inches and above, an arched wooden support frame is used, with custom foam inserts to secure the curved surfaces of the elbows, preventing deformation during transportation.

- Smart maritime loading:

- Small-sized items are nested together, while large-sized items are placed on individual pallets, increasing container space utilization by 35%.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.