HOT PRODUCTS TAGS

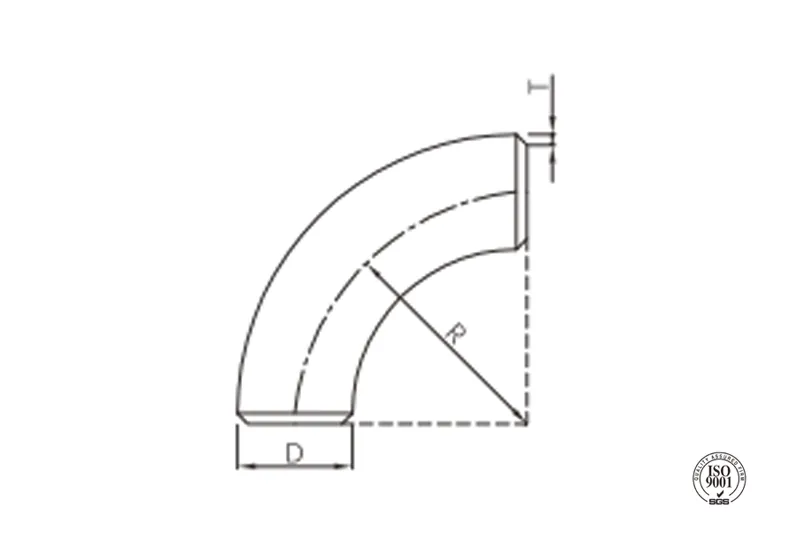

Butt weld 90° elbow (Long radius)

·Standard: ISO

EN 10253-1 / EN 10253-2 / EN 10253-3

·Material: Carbon steel S235 / P235TR2

SS equivalent to WP304 / WP316L

·Type: Long radius, 3D, R=1.5D

·W. pressure: Equal to same straight pipe

·Surface: Black painting / hot dip galvanized

Pickling white, etc.

·Size range: 1″-24″

description

butt weld 90 ° elbow (long radius), significantly reducing fluid resistance and energy loss, combined with butt weld connection to ensure high sealing and structural strength.

Specification

Available size

| Size | Preferred T to EN 10253-2(mm) | R(mm) | ||

| NPS | DN | OD(mm) | ||

| 1/2″ | 15 | 21.3 | 2.0/2.6/3.214.0/5.017.1 | 38 |

| 3/4″ | 20 | 26.9 | 2.3/2.6/3.2/4.0/4.5/5.6/8.0 | 38 |

| 1″ | 25 | 33.7 | 2.6/3.214.0/4.5/5.6/6.3/8.8 | 38 |

| 1-1/4″ | 32 | 42.4 | 2.6/3.614.0/5.0/6.3/8.0/10.0 | 48 |

| 1-1/2″ | 40 | 48.3 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 57 |

| 2″ | 50 | 60.3 | 2.9/3.614.0/5.6/7.1/8.8/11.0 | 76 |

| 2-1/2″ | 65 | 76.1 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 95 |

| 3″ | 80 | 88.9 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 114 |

| 4″ | 100 | 114.3 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 152 |

| 5″ | 125 | 139.7 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 190 |

| 6″ | 150 | 165.1/168.3 | 4.0/4.5/5.6/7.1/11.0/14.2/17.5/22.2 | 229 |

| 8″ | 200 | 219.1 | 4.5/6.3/7.1/8.0/12.5/16.0/17.5/22.2 | 305 |

| 10″ | 250 | 273.0 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 381 |

| 12″ | 300 | 323.9 | 5.617.1/8.8/10.0/12.5/17.5/25.0/32.0 | 457 |

| 14″ | 350 | 355.6 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 533 |

| 16″ | 400 | 406.4 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 610 |

| 18″ | 450 | 457 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 686 |

| 20″ | 500 | 508 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 762 |

| 24″ | 600 | 610 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 914 |

application

- Turn for fluid without loss, applicable to the occasions of the pipeline system that requires 90 turning only suitable to conduct media with high velocity(such as from main discharge pipe of pump station;from chemical material delivery line).

- Key energy-efficiency messages: Long-radius design (Curvature Radius= 1.5x pipe diameter) improves fluid dynamic performance making a platform suitable for energy saving applications including power stations, and ship propulsion systems.

- Severe Operating Conditions: dependable turning solution for high-temperature, high-pressure pipelines such as steam lines and slurry pipelines containing particulates.

advantages

- Low Loss of Pressure drop: A low loss PD by use of ling radius (LR) helps to reduce fluid resistance, pump energy and improve the system efficiency.

- Structural Toughness: Equivalent to straight pipe sections, suitable for high-pressure impulse and thermal stress deformation. Sizes in 1/2- to 6-in diam are available with male, female, flange, and welded endsProvides permanent zero-leakage sealing for welded jointsSuitable for corrosive/high-temperature media.

- Gradable:Carbon steel (S235/P235TR2): An industrial grade, cheap material that is fully gradable; Stainless steel (304/316L) — Hygiene Grade, Food- & Pharma-Grade, suitable for high-corrosive environment. Manufactured to European Standard EN 10253, suitable for meeting EU and international project needs.

- Installation-friendly design:Long radius design allows bending radius to be enlarged for stress concentration on pipeline to be reduced, prolonging lifespan of the system .

packing

- Specialized Protection for Curved Structures:

- Surface Treatment: Black paint (rust-proof carbon steel)/hot-dip galvanizing (outdoor environments)/pickling and passivation (stainless steel corrosion).

- Custom foam blocks are installed into the elbows to prevent deformation caused by impacts during transportation, film covering ensures surface will not be scratched.

- lTiered Packaging Solution:

- -Small elbows (≤6″): Packaged in pairs back-to-back, strapped groups.

- #Large elbows (>6″): One wooden case contain 3pcs semi-circle, thus avoid turning over with marking “TOP” .

- Smart Identification System:

- Outer box printed with flow direction arrows (inlet → outlet) and angle markings (90° LR).

- Affixed with standard codes (e.g., “EN 10253-2”) and material labels (e.g., “P235TR2”).

Available size

| Size | Preferred T to EN 10253-2(mm) | R(mm) | ||

| NPS | DN | OD(mm) | ||

| 1/2″ | 15 | 21.3 | 2.0/2.6/3.214.0/5.017.1 | 38 |

| 3/4″ | 20 | 26.9 | 2.3/2.6/3.2/4.0/4.5/5.6/8.0 | 38 |

| 1″ | 25 | 33.7 | 2.6/3.214.0/4.5/5.6/6.3/8.8 | 38 |

| 1-1/4″ | 32 | 42.4 | 2.6/3.614.0/5.0/6.3/8.0/10.0 | 48 |

| 1-1/2″ | 40 | 48.3 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 57 |

| 2″ | 50 | 60.3 | 2.9/3.614.0/5.6/7.1/8.8/11.0 | 76 |

| 2-1/2″ | 65 | 76.1 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 95 |

| 3″ | 80 | 88.9 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 114 |

| 4″ | 100 | 114.3 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 152 |

| 5″ | 125 | 139.7 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 190 |

| 6″ | 150 | 165.1/168.3 | 4.0/4.5/5.6/7.1/11.0/14.2/17.5/22.2 | 229 |

| 8″ | 200 | 219.1 | 4.5/6.3/7.1/8.0/12.5/16.0/17.5/22.2 | 305 |

| 10″ | 250 | 273.0 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 381 |

| 12″ | 300 | 323.9 | 5.617.1/8.8/10.0/12.5/17.5/25.0/32.0 | 457 |

| 14″ | 350 | 355.6 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 533 |

| 16″ | 400 | 406.4 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 610 |

| 18″ | 450 | 457 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 686 |

| 20″ | 500 | 508 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 762 |

| 24″ | 600 | 610 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 914 |

- Turn for fluid without loss, applicable to the occasions of the pipeline system that requires 90 turning only suitable to conduct media with high velocity(such as from main discharge pipe of pump station;from chemical material delivery line).

- Key energy-efficiency messages: Long-radius design (Curvature Radius= 1.5x pipe diameter) improves fluid dynamic performance making a platform suitable for energy saving applications including power stations, and ship propulsion systems.

- Severe Operating Conditions: dependable turning solution for high-temperature, high-pressure pipelines such as steam lines and slurry pipelines containing particulates.

- Low Loss of Pressure drop: A low loss PD by use of ling radius (LR) helps to reduce fluid resistance, pump energy and improve the system efficiency.

- Structural Toughness: Equivalent to straight pipe sections, suitable for high-pressure impulse and thermal stress deformation. Sizes in 1/2- to 6-in diam are available with male, female, flange, and welded endsProvides permanent zero-leakage sealing for welded jointsSuitable for corrosive/high-temperature media.

- Gradable:Carbon steel (S235/P235TR2): An industrial grade, cheap material that is fully gradable; Stainless steel (304/316L) — Hygiene Grade, Food- & Pharma-Grade, suitable for high-corrosive environment. Manufactured to European Standard EN 10253, suitable for meeting EU and international project needs.

- Installation-friendly design:Long radius design allows bending radius to be enlarged for stress concentration on pipeline to be reduced, prolonging lifespan of the system .

- Specialized Protection for Curved Structures:

- Surface Treatment: Black paint (rust-proof carbon steel)/hot-dip galvanizing (outdoor environments)/pickling and passivation (stainless steel corrosion).

- Custom foam blocks are installed into the elbows to prevent deformation caused by impacts during transportation, film covering ensures surface will not be scratched.

- lTiered Packaging Solution:

- -Small elbows (≤6″): Packaged in pairs back-to-back, strapped groups.

- #Large elbows (>6″): One wooden case contain 3pcs semi-circle, thus avoid turning over with marking “TOP” .

- Smart Identification System:

- Outer box printed with flow direction arrows (inlet → outlet) and angle markings (90° LR).

- Affixed with standard codes (e.g., “EN 10253-2”) and material labels (e.g., “P235TR2”).

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.