HOT PRODUCTS TAGS

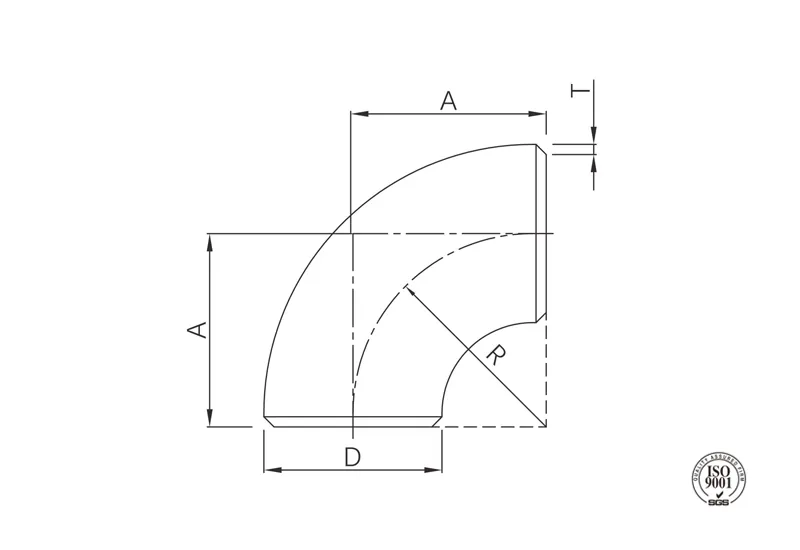

Butt weld 90° elbow (Short radius)

·Standard: ISO

ASME B16.9

·Material: Carbon steel ASTM A234, WPB

SS ASTM A403, WP304 / WP316L

·Type: Short radius, R=1.0D

·W. pressure: Equal to same seamless pipe

·Surface: Black painting / hot dip galvanized Pickling white, etc.

·Size range: 1″-24″

description

butt welding 90 ° elbow (short radius) is used to connect two pipes by butt welding, so that the pipe changes 90 degrees to change the direction of fluid flow, strong corrosion resistance, high fluid efficiency, safe and reliable structure.

Specification

Available size

| Size | Tnickness (mm) | A(mm) | ||||

| NPS | DN | OD(mm) | Sch10 | Sch40 | Sch80 | |

| 1″ | 25 | 33.4 | 2.77 | 3.38 | 4.55 | 25 |

| 1-1/4″ | 32 | 42.2 | 2.77 | 3.56 | 4.85 | 32 |

| 1-1/2″ | 40 | 48.3 | 2.77 | 3.68 | 5.08 | 38 |

| 2″ | 50 | 60.3 | 2.77 | 3.91 | 5.54 | 51 |

| 2-1/2″ | 65 | 73.0 | 3.05 | 5.16 | 7.01 | 64 |

| 3″ | 80 | 88.9 | 3.05 | 5.49 | 7.62 | 76 |

| 4″ | 100 | 114.3 | 3.05 | 6.02 | 8.56 | 102 |

| 5″ | 125 | 141.3 | 3.40 | 6.55 | 9.53 | 127 |

| 6″ | 150 | 168.3 | 3.40 | 7.11 | 10.97 | 152 |

| 8″ | 200 | 219.1 | 3.76 | 8.18 | 12.70 | 203 |

| 10″ | 250 | 273.0 | 4.19 | 9.27 | 15.09 | 254 |

| 12″ | 300 | 323.8 | 4.57 | 10.31 | 17.48 | 305 |

| 14″ | 350 | 355.6 | 6.35 | 11.13 | 19.05 | 356 |

| 16″ | 400 | 406.4 | 6.35 | 12.70 | 21.44 | 406 |

| 18″ | 450 | 457 | 6.35 | 14.27 | 23.83 | 457 |

| 20″ | 500 | 508 | 6.35 | 15.09 | 26.19 | 508 |

| 24″ | 600 | 610 | 6.35 | 17.48 | 30.96 | 610 |

Note: The thickness is available with Sch5, Sch10, Sch30, Sch40, Sch80, Sch120, Sch160, STD, XS, XXS, 5S, 10S, 40S, 80S, etc.

application

- Space-saving Right-angle Turning: It is mainly used for 90-degree sharp turning of narrow pipe systems, such as equipment rooms, ship piping and underground pipe galleries.

- Economical pipeline: only for long flow direction of small changes in the scene (such as equipment interfaces and branch pipe connection), reduce fewer pipes, and construction costs.

- Harsh Environment CompatibilityOffered in carbon steel and stainless steel for high-corrosion or clean applications such as chemicals, pharma, food.

- Flexible Selectable Full-Size: Covers the pipelining from 1 inch to 24 inches (DN25-DN600), which can meet the needs of small precision instrument and engineering pipeline network.

advantages

- Installation Space Saving 50%: turns subtracting half the space was developed from the short radius design is available in only a limited place piping.

- Tough anti-corrosion: a steel/stainless steel based material + surface treatment (galvanized/electrolysis galvanized) and can be highly resistant to rusty for a quite time and long service life.

- Zero leakage safety assurance:which can let you use it to transport dangerous substances without any worry of a single drop of leakage.

- Lifetime maintenance-free: nothing is loose after being fixed with this method, so there is no need to have regular inspections and maintenance further in life.

- Plug-and-play: adhere to international standards (ISO/ASME), seamlessly interface with global piping systems, customize less and lower costs. Pressure and temperature resistance: Pressure-bearing capacity is equal to the pipeline, for high-temperature high pressure such as steam hot oil.

packing

- Rust-proof and impact-resistant protection:

- Each item is wrapped in rust-proof film and foam corner protectors, then placed in a thickened cardboard box (marked: 90° short elbow, 4 inches).

- Stainless steel products are additionally wrapped in scratch-resistant pearl cotton.

- Large-size reinforcement solution:

- 6 inches and above use dedicated wooden brackets for elbows, with custom foam inserts to secure curved sections, preventing deformation during transportation.

- Efficient maritime loading:

- Small-size items are packed in nested sets, while large-size items are placed on individual wooden brackets, increasing container utilization by 30%.

Available size

| Size | Tnickness (mm) | A(mm) | ||||

| NPS | DN | OD(mm) | Sch10 | Sch40 | Sch80 | |

| 1″ | 25 | 33.4 | 2.77 | 3.38 | 4.55 | 25 |

| 1-1/4″ | 32 | 42.2 | 2.77 | 3.56 | 4.85 | 32 |

| 1-1/2″ | 40 | 48.3 | 2.77 | 3.68 | 5.08 | 38 |

| 2″ | 50 | 60.3 | 2.77 | 3.91 | 5.54 | 51 |

| 2-1/2″ | 65 | 73.0 | 3.05 | 5.16 | 7.01 | 64 |

| 3″ | 80 | 88.9 | 3.05 | 5.49 | 7.62 | 76 |

| 4″ | 100 | 114.3 | 3.05 | 6.02 | 8.56 | 102 |

| 5″ | 125 | 141.3 | 3.40 | 6.55 | 9.53 | 127 |

| 6″ | 150 | 168.3 | 3.40 | 7.11 | 10.97 | 152 |

| 8″ | 200 | 219.1 | 3.76 | 8.18 | 12.70 | 203 |

| 10″ | 250 | 273.0 | 4.19 | 9.27 | 15.09 | 254 |

| 12″ | 300 | 323.8 | 4.57 | 10.31 | 17.48 | 305 |

| 14″ | 350 | 355.6 | 6.35 | 11.13 | 19.05 | 356 |

| 16″ | 400 | 406.4 | 6.35 | 12.70 | 21.44 | 406 |

| 18″ | 450 | 457 | 6.35 | 14.27 | 23.83 | 457 |

| 20″ | 500 | 508 | 6.35 | 15.09 | 26.19 | 508 |

| 24″ | 600 | 610 | 6.35 | 17.48 | 30.96 | 610 |

Note: The thickness is available with Sch5, Sch10, Sch30, Sch40, Sch80, Sch120, Sch160, STD, XS, XXS, 5S, 10S, 40S, 80S, etc.

- Space-saving Right-angle Turning: It is mainly used for 90-degree sharp turning of narrow pipe systems, such as equipment rooms, ship piping and underground pipe galleries.

- Economical pipeline: only for long flow direction of small changes in the scene (such as equipment interfaces and branch pipe connection), reduce fewer pipes, and construction costs.

- Harsh Environment CompatibilityOffered in carbon steel and stainless steel for high-corrosion or clean applications such as chemicals, pharma, food.

- Flexible Selectable Full-Size: Covers the pipelining from 1 inch to 24 inches (DN25-DN600), which can meet the needs of small precision instrument and engineering pipeline network.

- Installation Space Saving 50%: turns subtracting half the space was developed from the short radius design is available in only a limited place piping.

- Tough anti-corrosion: a steel/stainless steel based material + surface treatment (galvanized/electrolysis galvanized) and can be highly resistant to rusty for a quite time and long service life.

- Zero leakage safety assurance:which can let you use it to transport dangerous substances without any worry of a single drop of leakage.

- Lifetime maintenance-free: nothing is loose after being fixed with this method, so there is no need to have regular inspections and maintenance further in life.

- Plug-and-play: adhere to international standards (ISO/ASME), seamlessly interface with global piping systems, customize less and lower costs. Pressure and temperature resistance: Pressure-bearing capacity is equal to the pipeline, for high-temperature high pressure such as steam hot oil.

- Rust-proof and impact-resistant protection:

- Each item is wrapped in rust-proof film and foam corner protectors, then placed in a thickened cardboard box (marked: 90° short elbow, 4 inches).

- Stainless steel products are additionally wrapped in scratch-resistant pearl cotton.

- Large-size reinforcement solution:

- 6 inches and above use dedicated wooden brackets for elbows, with custom foam inserts to secure curved sections, preventing deformation during transportation.

- Efficient maritime loading:

- Small-size items are packed in nested sets, while large-size items are placed on individual wooden brackets, increasing container utilization by 30%.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.