3PE Steel Pipe: The Ultimate Engineer’s Guide

Introduction

Think you are a project manager or lead engineer responsible for a multi-million pipeline project. The main engineering hurdle is that the medium is not simply yet transported but the pipeline must be ensured against external corrosion or any other risk to the structural and operational integrity for at least 50 years or more. The choice of coating is a key risk management decision in such capital-intensive projects. Early failure is not only a costly repair; it is potential catastrophic environmental and safety liability with great financial and reputational impact. So, your choice of a coating system needs to be based on solid facts and proven performance, rather than emotion, and you should consider more than just the initial expenses, but the full life-cycle cost and long-t0erm dependability of the asset.

The secret to addressing this situation for long-term protection is a good knowledge based on advanced coating systems. You need to go beyond just surface specs and look into material science, the degree of precision utilized in the application process, and how strict the quality standards are. The selection of different systems, e.g. 3-Layer Polyethylene (3PE Steel Pipe) and Fusion-Bonded Epoxy (FBE STEEL PIPE)has major implications on the operational life, maintenance expenses and overall Return on Investement of a project.

This book is a full, technical analysis of the 3PE coating system – for the engineer who wants to know the hard numbers. We will break down its three-layered matrix composite formation, explain the highly stringent manufacturing procedure, and deliver you a quantified, data-backed contrast to other systems. We will also explain the essential requirements for international standards such as DIN 30670 – so you can adequately specify a, procure and verify a coating system which offers true, decades-long asset protection.

The Body: An Engineer’s Deep Dive into 3PE Coatings

1. What is a 3PE Anticorrosion Coating? Deconstructing the “Three-Layer Armor”

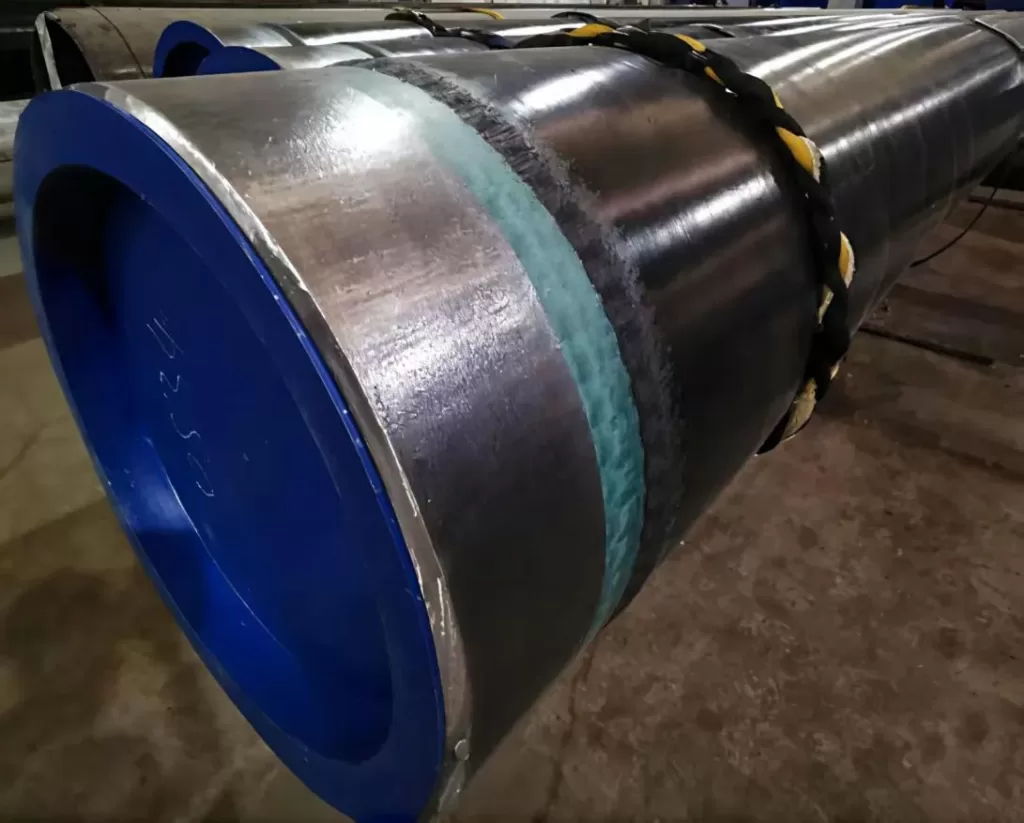

The 3PE coating is a performance based multilayer system designed to deliver the combined benefits of corrosion and mechanical resistance. Its name is based on the three different functional parts, because of the order in which these are produced to form a combined barrier that includes the best characteristic of each of the constituent materials.

The base of the system is a Fusion-Bonded Epoxy (FBE) Primer. This thermosetting powder, which is generally sprayed in multiple layers at a thickness of 80–150 micrometres (μm), is then strongly cross-linked bonded to the prepared steel surface. It is intended to be used as the main corrosion barrier layer providing high chemical resistance and isolating the under-film moisture from the anti-corrosive property. This adhesion is critical in bearing cathodic disbondment—a process where an electrochemical reaction causes the coating to debond from the steel near a coating flaw (holiday) when exposed cathodically to a protection system.The integrity of the FBE layer is the first line of defense against this highly critical mode of failure.

The Co-polymer Adhesive is the bonding agent for the primer and the outer mechanical layer. This intermediate layer is an advanced substance – frequently a maleic anhydride grafted polyethylene, but chemically modified by means of functional groups that develop a permanent, high strength bonding with both the epoxy primer under it and the polyethylene topcoat over it. It serves as a powerful tie-agent, bonding the system together so that it performs as one cohesive coat. In the absence of this critical adhesive tie, the system would be susceptible to delamination when subjected to the mechanical and thermal strains encountered during transport, installation, and use.

The ultimate and most apparent part is the Polyethylene (PE) Topcoat. This thick layer of high density polyethylene (HDPE) cover, which can be a few millimeters thick, is the most external part of the system and the first line of protection against the external physical environment. It offers superior protection against mechanical attack of strong abrasive soils, impact while being handled and backfilled, and long-term soil pressure. Carbon black is often added to formulations for UV resistance while stored outdoors.In addition, its high resistivity makes it an excellent insulating barrier which works synergistically with the cathodic protection system to serve as a strong, long lasting shield against the elements.

2. How is a 3PE Coating Applied? A Precision-Controlled Industrial Process

The application of a 3PE coating is an advanced factory-controlled process where precision in every step governs the end quality. The production process starts with aggressive Surface Preparation. The bare pipe is cleaned of any organic material and then subjected to aggressive abrasive blast cleaning with steel shot or grit to a near white metal finish (Sa 2.5).This not only cleans the steel, but also imparts a defined surface roughness, or anchor profile (usually 50-100 μm), which is required to establish a robust mechanical bond with the FBE primer .

After this key preparation, the pipe is subjected to fast, uniform Induction Heating, which elevates the surface temperature to a specific value, usually between 180°C and 220°C. This temperature control is non-negotiable as it controls the melting, flowing and curing behavior of the FBE powder. The coating process is then a quick, sequential operation. The thermosetting FBE powder is first electrostatically sprayed onto the rotating, heated pipe using a fluidised bed. The powder immediately melts, flows out as a homogeneous liquid film and starts to “gel”. Subsequently, while the FBE yet in the reactive “gel” phase, co-polymer adhesive and polyethylene layers are simultaneously extruded and laminated on the pipe in one single operation, either utilizing a side-extruded die (spiral wrapping) or a crosshead die (sleeve extrusion). Pressure rollers press these layers firmly together. The whole coated pipe is then subjected to a regulated water quenching unit to cool down the pipe, which solidifies the thermoplastic layers and also to complete curing of the FBE.Finally, the pipe ends are machined to form a “cutback”.

3. Quantitative Analysis: 3PE vs FBE Coating

Although single-layer FBE has proven to be an effective anti-corrosion coating, its main drawback is its relatively low resistance to mechanical damage. The 3-layer system: adhesive, PE, 3PE system (adhesive, PE, adhesive) which has a quantitative superior physical toughnessThis data-based comparison is at the heart of an engineering-approach analysis.

| Performance Metric | Single-Layer FBE (760-1000 μm) | 3PE System (1.8-4.0 mm) | Engineering Implication |

| Impact Resistance (ASTM G14) | Good (e.g., >1.5 J) | Excellent (e.g., >10 J) | 3PE offers >5x resistance to damage during transport, handling, and backfilling. |

| Abrasion Resistance | Moderate | Excellent | Superior protection against rocky backfill and soil stress, reducing the risk of coating breaches. |

| Water Permeability | Low | Extremely Low | The PE topcoat provides a superior barrier against moisture ingress, enhancing long-term corrosion protection. |

| Cathodic Disbondment Resistance | Excellent | Excellent | Both systems perform well, but 3PE’s superior mechanical barrier helps maintain this resistance over time by preventing initial damage. |

| Application Environment | Plant-applied; suitable for internal and external use. | Primarily for external use on buried or submerged pipelines. | The choice depends on whether the primary threat is corrosion alone or a combination of corrosion and mechanical stress. |

This data clearly demonstrates that 3PE should be the specified choice for pipelines in challenging environments where mechanical damage is a significant and probable risk.

4. Key Application Fields for 3PE Coated Pipes

The strength and durability of 3PE coatings allows them to be the solution for numerous demanding applications. In oil and gas, these are widely used for onshore and offshore transmission pipelines where they protect against aggressive soil environment and insulation damage due to mechanical handling during pipeline installation. 3PE coatings maintain the integrity of large diameter steel water mains, buried in municipal water supply and waste water systems, for long periods of time and prevent the corrosion that could develop into leaks and water contamination, and which could subsequently lead to breaks in the line. They are also a first choice for urban and cross-country natural gas networks, where safety and reliability above all else.

5. Decoding the Standards: Why DIN 30670 and ISO 21809 Matter

Technical standards make professional products different from commodities. For 3PE two of them are recognized world wide. DIN 30670 is the well-known German standard which defines important performance criteria in detail. It specifies the minimum coating thickness according to pipe diameter, the peel strength (e.g., >35 N/cm at 23°C) and the testing conditions for the impact resistance and the indentation hardness, which is essential to oppose the pressure of the rocks in the ground. Compliance with DIN 30670 is an unambiguous indication of a superior quality coating. ISO 21809 , is a comprehensive international standard which covers the pipeline transportation systems including material properties, application and inspection procedures to make sure of the quality worldwide. .

6. How to Verify 3PE Coating Quality?

Stringent quality control is a part of the coating process. A number of inspections are carried out, however, which prove that a 3PE coating is capable of meeting the high requirements of standards. The critical destructive test is the Peel Strength Test which allows us to directly measure adhesive bond strength by quantifying the force required to peel the coating from the pipe. An Impact Test is carried out by dropping a given weight from a given height; this test evaluates mechanical shock resistance of the coating. One of the most, if not the most important final inspection is the Holiday Test. Following quenching, the entire 100% of the pipe surface is scanned with high voltage detector (for instance, 25 kV).This Instrument will generate an electrical discharge exactly where any pinhole or void exist so that the location of any pinhole or void can be located and repaired before become potential weak points in the corrosion barrier.

Conclusion

The engineering benefit of the 3PE coating system is its composite structure, synergistically formed by the excellent corrosion resistivity of FBE and the superior mechanical toughness of polyethylene. Such a multi-layer system is capable of delivering long-term protection on a level that cannot be provided by a single-layer system and this should inform selection based on a risk assessment of the pipeline operating environment. A 3PE coating system can be used as a rule of thumb, where the higher initial investment is offset by the extended service time, when you are dealing with buried or submerged pipelines with high handling or backfill induced loads: a single-layer coating system will be proven unsuited for a good part of the service life of the pipeline; optionally you require greater abrasivity or you are particularly careful. On the other hand, single-layer FBE coating can be used for areas with no or minimal mechanical risk. In the end, achieving this degree of future-proof long-term integrity requires partnering with a supplier who understands that you– the customer– are investing in a piece of critical infrastructure. At Allland Steel Pipe, we go the extra mile to not only deliver the product but also the expertise and data-backed solutions. We consistently maintain the highest quality standards as per international standards like DIN 30670 so that you get a product engineered for utmost dependability and longer service life.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.

Related Articles

ASTM A53 vs. API 5L: A Guide to Selection and Application

Introduction:Technology differences determine success or failure, and selection needs to be “precise”

Steel Density Analysis: Core Differences between Mild and Medium Carbon Steels and Industrial Applications

3LPE coated steel pipe: a solid barrier in the field of industrial corrosion protection

3LPP coated pipe: anti-corrosion guard in high temperature and high pressure environment

FBE steel pipe: the technological armor of the steel defense line

HOT TAGS

latest posts

- Introduction:Technology differences determine success or failure, and selection needs to be “precise”

- FBE Steel Pipes: Corrosion Protection Redefined

- DIN 30671: A Guide to FBE Coating for Steel Pipes

- A Guide to Structural Pipe: ASTM A500vsEN10219

- Weld Seam Integrity: A Deep Dive into LSAW vs. SSAW Pipe