HOT PRODUCTS TAGS

Heavy-duty flexible grooved coupling

·Standard: ANSI / UL 213 UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Bolt & nut: Carbon steel

·Gasket: EPDM, nitrile, silicone rubber, etc

·Rated pressure: 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 2″ – 12″

description

Heavy-duty flexible grooved couplings are high-strength flexible pipe fittings, used in pipeline systems with high load-bearing requirements. They allow for a certain relative displacement between pipes to compensate for deformation or absorb vibration

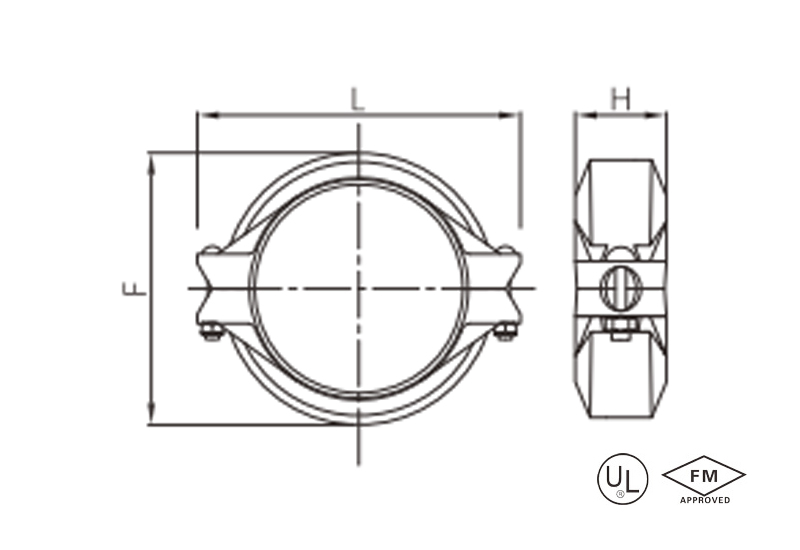

Specification

Available size

Size | Dimension (mm) | Bolting (n x bolt size) | |||||

Inch | DN | mm | F | L | H | ANSI | EN |

2″ | 50 | 60.3 | 90 | 134 | 45 | 2 – 1/2″ × 75 | 2 – M12 × 76 |

2-1/2″ | 65 | 73.0 | 100 | 150 | 45 | 2 – 1/2″ × 75 | 2 – M12 × 76 |

2-1/2″ | 65 | 76.1 | 102 | 154 | 45 | 2 – 1/2″ × 75 | 2 – M12 × 76 |

3″ | 80 | 88.9 | 121 | 172 | 45 | 2 – 1/2″ × 75 | 2 – M12 × 76 |

4″ | 100 | 114.3 | 151 | 214 | 50 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

5″ | 125 | 139.7 | 178 | 247 | 52 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

5″ | 125 | 141.3 | 180 | 248 | 51 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

6″ | 150 | 165.1 | 205 | 278 | 51 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

6″ | 150 | 168.3 | 208 | 284 | 51 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

8″ | 200 | 219.1 | 268 | 354 | 61 | 2 – 7/8″ × 140 | 2 – M22 × 140 |

10″ | 250 | 273.0 | 317 | 418 | 67 | 2 – 1″ × 165 | 2 – M24 × 165 |

12″ | 300 | 323.9 | 375 | 464 | 68 | 2 – 1″ × 165 | 2 – M24 × 165 |

application

- Heavy-load Pipeline Vibration Damping: Suitable for the fields of large-scale pumps/compressors/vessels inlets and outlets, power & industrial pipelines, fire protection project main lines with high pressure and vibration damping needs;

- Dynamic displacement compensation : Applicable for pipelines in areas with larger thermal expansion and contraction movement or foundation settlement; achieving the bypass of displacement while keeping connecting safe.

- High Safety Standard Facility, Ultra-critical applications: Certified by UL/FM for fire safety and used in hospitals or airports where any leaks are not allowed.

- Supports pipe diameters from 2 inches to 12 inches (DN50-DN300): Compatible with steel and ductile iron pipes.

advantages

1. High Strength & Flexibility: Rough design offers high loading capacity, flexible structure absorbs impact under load, and helps protect the pipeline from vibration damage.

2. Smart displacement adjustment: Automatically compensates thermal CNC machining and contraction or slight displacement of pipes to avoid excessive stress at connections which may cause cracking.

3. Sealing design: Top plateau sealing can maintain zero leakage of water, oil and gas media under high pressure (500 psi).

4. Fast to Install: Grove connections do not require welding nor perfect alignment — just fit and tighten the bolts, which saves more than 50% in labor hours.

5. Long life: The body of ductile iron, inner and exteneral corrosion resistant coating (red paint/galvanized), anti-corrosion and wear-resistant, will not can be used in underground or humid environments.

6. Quick maintenance: the dismountable design makes it easy to replace gasket or bolts, without cutting from pipeline, save much maintain cost.

packing

- Industrial-grade protection:

- Each item is individually packaged in a hard cardboard box, with a moisture-proof bag and installation guide included inside.

- The outer box is clearly labeled: Heavy-duty flexible joint, 8 inches, high pressure.

- Large-Size Reinforcement:

- 6 inches and above use custom wooden boxes + anti-vibration foam, with special protection for flanges and moving parts.

- Bulk Transportation:

- Metal pallets for support, wrapped with stretch film + steel straps for fixation, suitable for long-distance sea/land transport, ensuring safe delivery

Available size

Size | Dimension (mm) | Bolting (n x bolt size) | |||||

Inch | DN | mm | F | L | H | ANSI | EN |

2″ | 50 | 60.3 | 90 | 134 | 45 | 2 – 1/2″ × 75 | 2 – M12 × 76 |

2-1/2″ | 65 | 73.0 | 100 | 150 | 45 | 2 – 1/2″ × 75 | 2 – M12 × 76 |

2-1/2″ | 65 | 76.1 | 102 | 154 | 45 | 2 – 1/2″ × 75 | 2 – M12 × 76 |

3″ | 80 | 88.9 | 121 | 172 | 45 | 2 – 1/2″ × 75 | 2 – M12 × 76 |

4″ | 100 | 114.3 | 151 | 214 | 50 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

5″ | 125 | 139.7 | 178 | 247 | 52 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

5″ | 125 | 141.3 | 180 | 248 | 51 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

6″ | 150 | 165.1 | 205 | 278 | 51 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

6″ | 150 | 168.3 | 208 | 284 | 51 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

8″ | 200 | 219.1 | 268 | 354 | 61 | 2 – 7/8″ × 140 | 2 – M22 × 140 |

10″ | 250 | 273.0 | 317 | 418 | 67 | 2 – 1″ × 165 | 2 – M24 × 165 |

12″ | 300 | 323.9 | 375 | 464 | 68 | 2 – 1″ × 165 | 2 – M24 × 165 |

- Heavy-load Pipeline Vibration Damping: Suitable for the fields of large-scale pumps/compressors/vessels inlets and outlets, power & industrial pipelines, fire protection project main lines with high pressure and vibration damping needs;

- Dynamic displacement compensation : Applicable for pipelines in areas with larger thermal expansion and contraction movement or foundation settlement; achieving the bypass of displacement while keeping connecting safe.

- High Safety Standard Facility, Ultra-critical applications: Certified by UL/FM for fire safety and used in hospitals or airports where any leaks are not allowed.

- Supports pipe diameters from 2 inches to 12 inches (DN50-DN300): Compatible with steel and ductile iron pipes.

1. High Strength & Flexibility: Rough design offers high loading capacity, flexible structure absorbs impact under load, and helps protect the pipeline from vibration damage.

2. Smart displacement adjustment: Automatically compensates thermal CNC machining and contraction or slight displacement of pipes to avoid excessive stress at connections which may cause cracking.

3. Sealing design: Top plateau sealing can maintain zero leakage of water, oil and gas media under high pressure (500 psi).

4. Fast to Install: Grove connections do not require welding nor perfect alignment — just fit and tighten the bolts, which saves more than 50% in labor hours.

5. Long life: The body of ductile iron, inner and exteneral corrosion resistant coating (red paint/galvanized), anti-corrosion and wear-resistant, will not can be used in underground or humid environments.

6. Quick maintenance: the dismountable design makes it easy to replace gasket or bolts, without cutting from pipeline, save much maintain cost.

- Industrial-grade protection:

- Each item is individually packaged in a hard cardboard box, with a moisture-proof bag and installation guide included inside.

- The outer box is clearly labeled: Heavy-duty flexible joint, 8 inches, high pressure.

- Large-Size Reinforcement:

- 6 inches and above use custom wooden boxes + anti-vibration foam, with special protection for flanges and moving parts.

- Bulk Transportation:

- Metal pallets for support, wrapped with stretch film + steel straps for fixation, suitable for long-distance sea/land transport, ensuring safe delivery

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.