HOT PRODUCTS TAGS

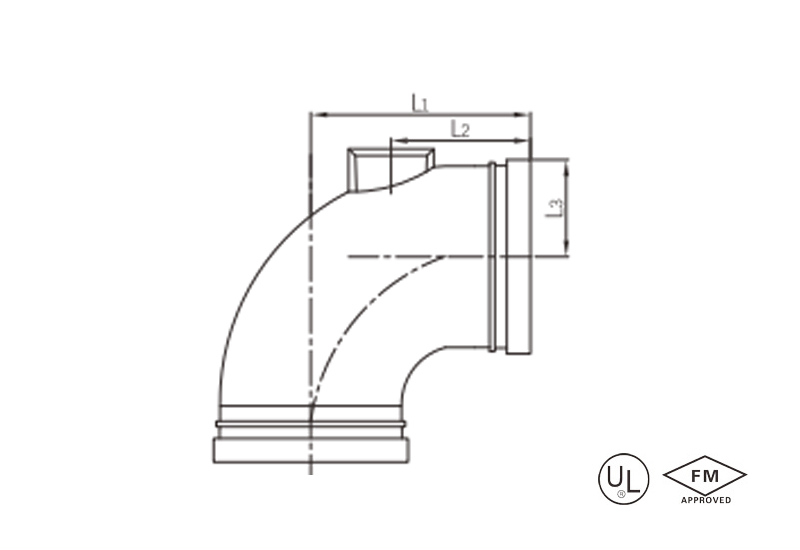

Grooved 90° drainage elbow

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 2″ – 8″

description

Grooved 90° drainage elbow is a 90-degree drainage elbow with a grooved connection structure, which changes the direction of water flow through grooved connection.

Specification

Available size

Size | Center to end,L(mm) | ||||

Inch | DN | mm | L1 | L2 | L3 |

2″ | 50 | 60.3 | 83 | 65 | 37.5 |

2-1/2″ | 65 | 73.0 | 95 | 70 | 43.5 |

3″ | 80 | 88.9 | 108 | 70 | 53 |

4″ | 100 | 114.3 | 127 | 70 | 66 |

6″ | 150 | 168.3 | 165 | 70 | 92.5 |

8″ | 200 | 219.1 | 197 | 70 | 116 |

application

- Grooved 90° drain elbow specifically designed for piping systems requiring a right-angle turn and simultaneous drainage

- Fire pump room piping low point sludge discharge port diversion;

- HVAC condensate drain pipe bottom diversion and discharge;

- Industrial workshop oil/chemical liquid collection pipe corner drainage;

- Food factory CIP cleaning pipeline right-angle drainage;

- Ship ballast water pipeline corner with limited space;

- Underground pipeline maintenance well gravity drainage outlet direction adjustment.

advantages

1. Drain orientation at bottom and directing ability: 90° elbow with a drainage hole at the bottom , where both draining and pipe directional functions are actually combined together.

2. Small size and structure design: Integrated ratio of L1/L2/L3 dimensions (refer to the document parameter) easily installed in limited space.

3. Follow installation: groove clamp connection, no welding required, 70% of labor time compared to traditional drainage elbow.

4. Pressure resistance: Ductile iron endures water hammer shock, and the hot-dip galvanized coating tolerates acidic and alkaline media, promising a service life of ≥10 years.

5. Guaranteed safety certification : UL/FM with no leakage and 300-500 psi minimum pressure.

packing

- Individual protection: Drain holes filled with wax to prevent blockage + bend inner walls coated with anti-rust oil + joints wrapped with bubble wrap.

- 2“-4” specifications: High-strength corrugated cardboard boxes + EPE foam partitions for secure fixation, with no more than 2 pieces per box.

- 6“-8” specifications: Five-layer reinforced cardboard boxes + custom foam molds, with corner sleeves for reinforcement.

- Labeling system: Outer box printed with “drainage hole facing down” orientation icon, clearly marked specifications (e.g., “90° drainage elbow 4” DN100 L1=127mm“), ‘Fragile’ and ”Moisture-proof” icons + UL/FM certification mark.

- Export compliance: Complies with ISTA 3A standards, 8″ specifications available in wooden boxes.

Available size

Size | Center to end,L(mm) | ||||

Inch | DN | mm | L1 | L2 | L3 |

2″ | 50 | 60.3 | 83 | 65 | 37.5 |

2-1/2″ | 65 | 73.0 | 95 | 70 | 43.5 |

3″ | 80 | 88.9 | 108 | 70 | 53 |

4″ | 100 | 114.3 | 127 | 70 | 66 |

6″ | 150 | 168.3 | 165 | 70 | 92.5 |

8″ | 200 | 219.1 | 197 | 70 | 116 |

- Grooved 90° drain elbow specifically designed for piping systems requiring a right-angle turn and simultaneous drainage

- Fire pump room piping low point sludge discharge port diversion;

- HVAC condensate drain pipe bottom diversion and discharge;

- Industrial workshop oil/chemical liquid collection pipe corner drainage;

- Food factory CIP cleaning pipeline right-angle drainage;

- Ship ballast water pipeline corner with limited space;

- Underground pipeline maintenance well gravity drainage outlet direction adjustment.

1. Drain orientation at bottom and directing ability: 90° elbow with a drainage hole at the bottom , where both draining and pipe directional functions are actually combined together.

2. Small size and structure design: Integrated ratio of L1/L2/L3 dimensions (refer to the document parameter) easily installed in limited space.

3. Follow installation: groove clamp connection, no welding required, 70% of labor time compared to traditional drainage elbow.

4. Pressure resistance: Ductile iron endures water hammer shock, and the hot-dip galvanized coating tolerates acidic and alkaline media, promising a service life of ≥10 years.

5. Guaranteed safety certification : UL/FM with no leakage and 300-500 psi minimum pressure.

- Individual protection: Drain holes filled with wax to prevent blockage + bend inner walls coated with anti-rust oil + joints wrapped with bubble wrap.

- 2“-4” specifications: High-strength corrugated cardboard boxes + EPE foam partitions for secure fixation, with no more than 2 pieces per box.

- 6“-8” specifications: Five-layer reinforced cardboard boxes + custom foam molds, with corner sleeves for reinforcement.

- Labeling system: Outer box printed with “drainage hole facing down” orientation icon, clearly marked specifications (e.g., “90° drainage elbow 4” DN100 L1=127mm“), ‘Fragile’ and ”Moisture-proof” icons + UL/FM certification mark.

- Export compliance: Complies with ISTA 3A standards, 8″ specifications available in wooden boxes.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.