HOT PRODUCTS TAGS

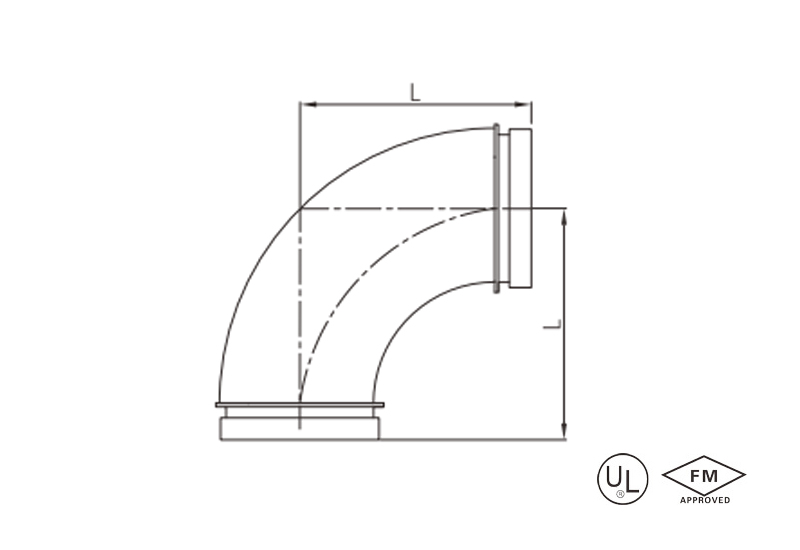

Grooved 90° elbow

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Type: Short / Standard / Long

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 1″ – 24″

description

Grooved 90° elbow is a 90-degree elbow pipe fitting with a grooved connection structure, used in pipeline systems to change the direction of the pipeline.

Specification

Available size

Size | Center to end, L(mm) | ||||

Inch | DN | mm | Short | Standard | Long |

1″ | 25 | 33.7 | 57 | 57 | / |

1-1/4″ | 32 | 42.4 | 60 | 70 | / |

1-1/2″ | 40 | 48.3 | 60 | 70 | / |

2″ | 50 | 60.3 | 70 | 83 | 111 |

2-1/2″ | 65 | 73.0 | 76 | 95 | 130 |

2-1/2″ | 65 | 76.1 | 76 | 95 | / |

3″ | 80 | 88.9 | 86 | 108 | 149 |

4″ | 100 | 114.3 | 102 | 127 | 191 |

5” | 125 | 139.7 | 122 | 140 | / |

5″ | 125 | 141.3 | 122 | 140 | / |

6″ | 150 | 165.1 | 140 | 165 | / |

6″ | 150 | 168.3 | 140 | 165 | 273 |

8″ | 200 | 219.1 | 175 | 197 | 362 |

10″ | 250 | 273.0 | 215 | 229 | 381 |

12″ | 300 | 323.9 | 245 | 254 | 457 |

14″ | 350 | 355.6 | / | 280 | / |

16″ | 400 | 406.4 | / | 305 | / |

18″ | 450 | 457.2 | / | 394 | / |

20″ | 500 | 508 | / | 438 | / |

24″ | 600 | 609.6 | / | 508 | / |

application

- Grooved 90° elbows are used for right-angle turns in piping systems.

- They cover fire sprinkler networks and avoid building structures.

- They optimize the layout of HVAC piping space.

- They adjust the direction of industrial fluid conveyance (chemical/water supply and drainage/oil and gas).

- They enable compact space turns in ship piping.

- They connect large factory networks across equipment, and are suitable for all pipe sizes from 1“ to 24”.

advantages

1. Narrow turning: three models (short, medium and long) for different bending radii, reduce fluid resistance.

2. Mins to be Insatall :Gropo clamp connection, no need of wielding, and 80% time saving compare with traditional flange installation.

3. Improved Pressure Bearing Structure: It ensures no leakage in high-pressure conditions between (300-500) psi the ductile iron body with resist water hammer impact.

4. Weatherability: Hot-dip galvanized /red painting surface corrosion resistance, UV-resistant and EN 45 years sea water resistant.

5. International safety certification: UL/FM certification, fire protection standard, industrial pipeline security

packing

- Single-item protection: The inner walls of the elbows are coated with anti-rust oil, and the joints are wrapped with cushioning film to prevent deformation caused by transportation collisions.

- Small sizes (1“-6”): Short/standard type: Corrugated cardboard box + EPE foam dividers, with no more than 4 pieces per box. Long type: Extended cardboard box + custom foam brackets

- Large sizes (8“-24”): Five-layer reinforced cardboard box + honeycomb cardboard corner protectors (8“-12”). Custom wooden boxes + steel banding (14“-24”), lined with moisture-proof paper .

- Labeling system: Outer box printed with elbow angle diagram, clearly marked with type (e.g., “Standard Type DN150”), ‘Fragile’ and “Do Not Press” icons + UL/FM certification marks

- Export compliance: Complies with ISTA 3E transportation standards; oversized dimensions provided with individual wooden boxes.

Available size

Size | Center to end, L(mm) | ||||

Inch | DN | mm | Short | Standard | Long |

1″ | 25 | 33.7 | 57 | 57 | / |

1-1/4″ | 32 | 42.4 | 60 | 70 | / |

1-1/2″ | 40 | 48.3 | 60 | 70 | / |

2″ | 50 | 60.3 | 70 | 83 | 111 |

2-1/2″ | 65 | 73.0 | 76 | 95 | 130 |

2-1/2″ | 65 | 76.1 | 76 | 95 | / |

3″ | 80 | 88.9 | 86 | 108 | 149 |

4″ | 100 | 114.3 | 102 | 127 | 191 |

5” | 125 | 139.7 | 122 | 140 | / |

5″ | 125 | 141.3 | 122 | 140 | / |

6″ | 150 | 165.1 | 140 | 165 | / |

6″ | 150 | 168.3 | 140 | 165 | 273 |

8″ | 200 | 219.1 | 175 | 197 | 362 |

10″ | 250 | 273.0 | 215 | 229 | 381 |

12″ | 300 | 323.9 | 245 | 254 | 457 |

14″ | 350 | 355.6 | / | 280 | / |

16″ | 400 | 406.4 | / | 305 | / |

18″ | 450 | 457.2 | / | 394 | / |

20″ | 500 | 508 | / | 438 | / |

24″ | 600 | 609.6 | / | 508 | / |

- Grooved 90° elbows are used for right-angle turns in piping systems.

- They cover fire sprinkler networks and avoid building structures.

- They optimize the layout of HVAC piping space.

- They adjust the direction of industrial fluid conveyance (chemical/water supply and drainage/oil and gas).

- They enable compact space turns in ship piping.

- They connect large factory networks across equipment, and are suitable for all pipe sizes from 1“ to 24”.

1. Narrow turning: three models (short, medium and long) for different bending radii, reduce fluid resistance.

2. Mins to be Insatall :Gropo clamp connection, no need of wielding, and 80% time saving compare with traditional flange installation.

3. Improved Pressure Bearing Structure: It ensures no leakage in high-pressure conditions between (300-500) psi the ductile iron body with resist water hammer impact.

4. Weatherability: Hot-dip galvanized /red painting surface corrosion resistance, UV-resistant and EN 45 years sea water resistant.

5. International safety certification: UL/FM certification, fire protection standard, industrial pipeline security

- Single-item protection: The inner walls of the elbows are coated with anti-rust oil, and the joints are wrapped with cushioning film to prevent deformation caused by transportation collisions.

- Small sizes (1“-6”): Short/standard type: Corrugated cardboard box + EPE foam dividers, with no more than 4 pieces per box. Long type: Extended cardboard box + custom foam brackets

- Large sizes (8“-24”): Five-layer reinforced cardboard box + honeycomb cardboard corner protectors (8“-12”). Custom wooden boxes + steel banding (14“-24”), lined with moisture-proof paper .

- Labeling system: Outer box printed with elbow angle diagram, clearly marked with type (e.g., “Standard Type DN150”), ‘Fragile’ and “Do Not Press” icons + UL/FM certification marks

- Export compliance: Complies with ISTA 3E transportation standards; oversized dimensions provided with individual wooden boxes.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.