HOT PRODUCTS TAGS

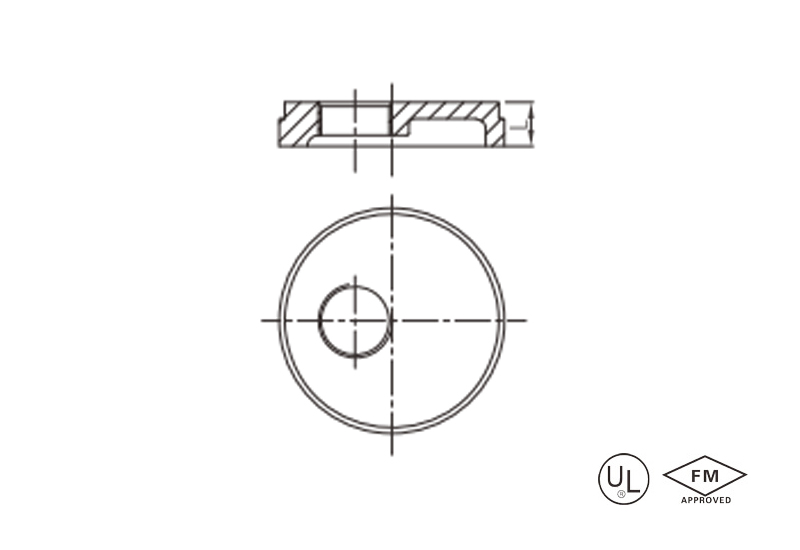

Grooved drain cap with eccentric hole

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Eccentric hole: Female thread, NPT / BSPT

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 1-1/2″×1″ – 8″×2″

description

Grooved drain cap with eccentric hole is a drainage cap with a grooved connection structure. The opening position is off-center from the center of the cap. It is installed at the end of the pipe through a grooved connection and can be used for directional drainage or to fit the requirements of a particular pipe layout

Specification

Available size

Size | End to end | ||

Inch | DN | mm | L(mm) |

1-1/2″ × 1″ | 40 × 25 | 48.3 × 33.7 | 24 |

2″ × 1/2″ | 50 × 15 | 60.3 × 21.3 | 24 |

2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 25 |

2″ × 1-1/2″ | 50 × 40 | 60.3 × 48.3 | 25 |

2-1/2″ × 1/2″ | 65 × 15 | 73.0 × 21.3 | 24 |

2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 25 |

2-1/2″ × 1″ | 65 × 25 | 76.1 × 33.7 | 24 |

2-1/2″ × 1-1/2″ | 65 × 40 | 76.1 × 48.3 | 25 |

2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 25 |

3″ × 1/2″ | 80 × 15 | 88.9 × 21.3 | 24 |

3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 24 |

3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 24 |

3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 24 |

4″ × 1/2″ | 100 × 15 | 114.3 × 21.3 | 25 |

4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 27 |

4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 27 |

4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 27 |

5″ × 1-1/2″ | 125 × 40 | 139.7 × 48.3 | 27 |

5″ × 2″ | 125 × 50 | 139.7 × 60.3 | 27 |

6″ × 1-1/2″ | 150 × 40 | 165.1 × 48.3 | 27 |

6″ × 1″ | 150 × 25 | 168.3 × 33.7 | 25 |

6″ × 1-1/2″ | 150 × 40 | 168.3 × 48.3 | 27 |

6″ × 2″ | 150 × 50 | 168.3 × 60.3 | 27 |

8″ × 1-1/2″ | 200 × 40 | 219.1 × 48.3 | 30 |

8″ × 2″ | 200 × 50 | 219.1 × 60.3 | 30 |

application

- Precise drainage from the lowest point of fire protection pipes;

- complete drainage of condensate from HVAC system pipes;

- offset drainage for industrial pipes (chemical/food/shipping) with layout restrictions;

- prevention of sediment accumulation at tank farm drainage outlets;

- sloped drainage from underground pipe network inspection wells;

- and drainage valve connections that avoid obstacles in special spaces.

advantages

1. Off-Center hole positions (NPT/BSPT internal threads) aid in guiding the flow and allows complete drainage of leftover Liquid from dead corners(Directional Drain Design).

2. Complex layout adaptation: Non-centrolized structure applicable for complicated pipe obstacles, solve problems of installation in space-limited environments.

3. Quick sealing for 3.30 seconds: one-click locking of the groove clamps and direct linkage to the drainage equipment of threaded holes increase the efficiency by 60 %.

4. Long Service Life: The thickness of the hot dip galvanizing coating is greater than 85um, with service life more than 10 years;Anti-strong current resistance: It can resist temporary over-currents above 50KA produced by lightning dischargeetal runoff and splits underground.

5. Safety is pressure certified: UL/FM approval, no leaks at 300 psi–500 diff.

packing

- Single-item protection: wax injection into drainage holes + anti-rust oil coating + bubble wrap full coverage, labeled with “off-center hole orientation.”

- Small sizes (1-1/2“-4”): corrugated cardboard box with EPE foam layers for secure fixation, with threaded dust cover.

- Large sizes (5“-8”): Five-layer reinforced cardboard box + custom foam mold, reinforced with steel straps at all four corners.

- Outer box labeling: Red “offset hole direction ↑” warning icon, product name (e.g., “Grooved Offset Drain End Cap 3”×2“ BSPT”), quantity/gross weight/net weight, UL/FM certification markings.

- Export compliance: Complies with ISTA 3A standards; 8″ size available in wooden boxes.

Available size

Size | End to end | ||

Inch | DN | mm | L(mm) |

1-1/2″ × 1″ | 40 × 25 | 48.3 × 33.7 | 24 |

2″ × 1/2″ | 50 × 15 | 60.3 × 21.3 | 24 |

2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 25 |

2″ × 1-1/2″ | 50 × 40 | 60.3 × 48.3 | 25 |

2-1/2″ × 1/2″ | 65 × 15 | 73.0 × 21.3 | 24 |

2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 25 |

2-1/2″ × 1″ | 65 × 25 | 76.1 × 33.7 | 24 |

2-1/2″ × 1-1/2″ | 65 × 40 | 76.1 × 48.3 | 25 |

2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 25 |

3″ × 1/2″ | 80 × 15 | 88.9 × 21.3 | 24 |

3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 24 |

3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 24 |

3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 24 |

4″ × 1/2″ | 100 × 15 | 114.3 × 21.3 | 25 |

4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 27 |

4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 27 |

4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 27 |

5″ × 1-1/2″ | 125 × 40 | 139.7 × 48.3 | 27 |

5″ × 2″ | 125 × 50 | 139.7 × 60.3 | 27 |

6″ × 1-1/2″ | 150 × 40 | 165.1 × 48.3 | 27 |

6″ × 1″ | 150 × 25 | 168.3 × 33.7 | 25 |

6″ × 1-1/2″ | 150 × 40 | 168.3 × 48.3 | 27 |

6″ × 2″ | 150 × 50 | 168.3 × 60.3 | 27 |

8″ × 1-1/2″ | 200 × 40 | 219.1 × 48.3 | 30 |

8″ × 2″ | 200 × 50 | 219.1 × 60.3 | 30 |

- Precise drainage from the lowest point of fire protection pipes;

- complete drainage of condensate from HVAC system pipes;

- offset drainage for industrial pipes (chemical/food/shipping) with layout restrictions;

- prevention of sediment accumulation at tank farm drainage outlets;

- sloped drainage from underground pipe network inspection wells;

- and drainage valve connections that avoid obstacles in special spaces.

1. Off-Center hole positions (NPT/BSPT internal threads) aid in guiding the flow and allows complete drainage of leftover Liquid from dead corners(Directional Drain Design).

2. Complex layout adaptation: Non-centrolized structure applicable for complicated pipe obstacles, solve problems of installation in space-limited environments.

3. Quick sealing for 3.30 seconds: one-click locking of the groove clamps and direct linkage to the drainage equipment of threaded holes increase the efficiency by 60 %.

4. Long Service Life: The thickness of the hot dip galvanizing coating is greater than 85um, with service life more than 10 years;Anti-strong current resistance: It can resist temporary over-currents above 50KA produced by lightning dischargeetal runoff and splits underground.

5. Safety is pressure certified: UL/FM approval, no leaks at 300 psi–500 diff.

- Single-item protection: wax injection into drainage holes + anti-rust oil coating + bubble wrap full coverage, labeled with “off-center hole orientation.”

- Small sizes (1-1/2“-4”): corrugated cardboard box with EPE foam layers for secure fixation, with threaded dust cover.

- Large sizes (5“-8”): Five-layer reinforced cardboard box + custom foam mold, reinforced with steel straps at all four corners.

- Outer box labeling: Red “offset hole direction ↑” warning icon, product name (e.g., “Grooved Offset Drain End Cap 3”×2“ BSPT”), quantity/gross weight/net weight, UL/FM certification markings.

- Export compliance: Complies with ISTA 3A standards; 8″ size available in wooden boxes.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.