HOT PRODUCTS TAGS

Grooved reducing cross

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 2-1/2″×2″ – 8″×6″

description

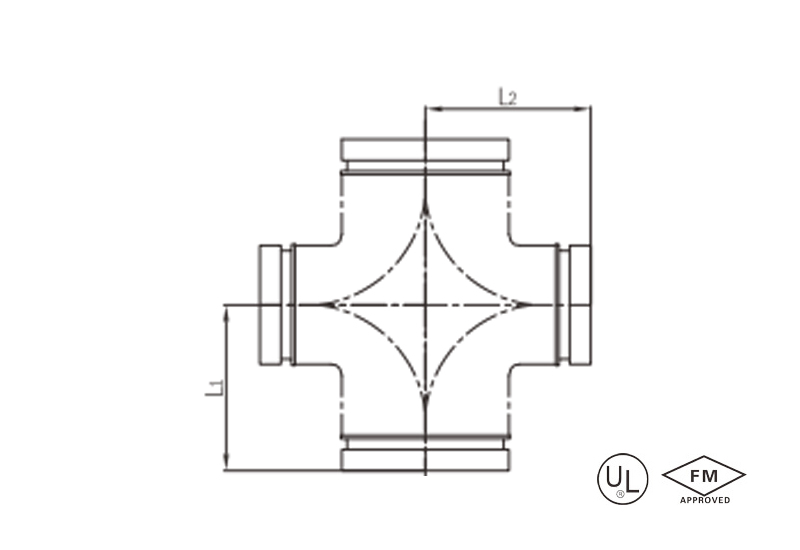

Grooved reducing cross is a reducer four-way pipe fitting. The interface pipe diameters are not exactly the same and are distributed in a cross shape, which is used to achieve cross-shaped branch connections of pipelines with different pipe diameters.

Specification

Available size

Size | Center to end(mm) | |||

Inch | DN | mm | L1 | L2 |

2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 76 | 76 |

3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 86 | 86 |

4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 101 | 101 |

4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 101 | 101 |

5″ × 4″ | 125 × 100 | 139.7 × 114.3 | 124 | 124 |

6″ × 2″ | 150 × 50 | 165.1 × 60.3 | 140 | 140 |

6″ × 2-1/2″ | 150 × 65 | 165.1 × 76.1 | 140 | 140 |

6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 140 | 140 |

6″ × 4″ | 150 × 100 | 165.1 × 114.3 | 140 | 140 |

6″ × 2″ | 150 × 50 | 168.3 × 60.3 | 140 | 140 |

8″ × 2″ | 200 × 50 | 219.1 × 60.3 | 175 | 175 |

8″ × 4″ | 200 × 100 | 219.1 × 114.3 | 175 | 175 |

8″ × 5″ | 200 × 125 | 219.1 × 139.7 | 175 | 175 |

8″ × 6″ | 200 × 150 | 219.1 × 165.1 | 175 | 175 |

application

- Toggle the multi-branch distribution hub: which is especially suitable for industrial systems with crisscross branches of media in different directions, and has four ports of different diameters to meet the requirements of several channel distributions of fluid.

- Compact design: Space-saving, reducing number of fittings and tee diameter for maximum layout flexibility (Ideal in equipment-intensive plant areas such as chemical plants, power stations)

- Renovation and Expansion of the System: It could be to enhance succeed water treatment, HVAC systems and other situations that need two-way expansion, expanding into pipes of different sizes.

advantages

1. Pic.2 Precise flume damper flows with four-way midline structure suitable for complex diverter requirements, reduces turbulent energy losses at the switching point and increases system energy efficiency.

2. Earth Quake resistance and leak free : The Grooved clamp connections have approvals from UL/FM, The Only type fitting with 300-500 psi furthur to the pressure, can withstand water hammer and also mechanical Vibration.

3. Quick Installation: four-point synchronous smooth groove without welding or flange alignment, reducing the construction time by more than 60%.

4. Excellent longevity: Red paint or Hot -dip galvanized surface treatment ensure long-term protection from moisture and chemical corrosion that promises the service life will also be increased by more 50%.

5. Flexible Adaptability: can support 2-1/2”×2” to 8”×6” (DN65 ~ DN200)multi-specifications, suitable for the core node of mid-size industrial pipeline network.

packing

- Multi-directional interface protection:

- Each port is covered with PE anti-scratch film + custom EVA foam corner protectors, with plastic support frames installed at cross intersections to prevent collision deformation;

- Compression-resistant layered packaging:

- ≤6″: Single piece nested in a reinforced cardboard box with honeycomb paperboard partitions, filled with shock-absorbing bubble columns inside;

- >6“: The main body is secured with a ”cross-shaped” wooden frame and suspended within a steel-band reinforced box.

- Anti-error transportation system:

- Boxes are printed with interface size distribution diagrams and pressure rating warning labels;

- QR codes are provided for scanning to access branch flow installation guidelines, preventing incorrect pipe diameter connections.

Available size

Size | Center to end(mm) | |||

Inch | DN | mm | L1 | L2 |

2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 76 | 76 |

3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 86 | 86 |

4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 101 | 101 |

4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 101 | 101 |

5″ × 4″ | 125 × 100 | 139.7 × 114.3 | 124 | 124 |

6″ × 2″ | 150 × 50 | 165.1 × 60.3 | 140 | 140 |

6″ × 2-1/2″ | 150 × 65 | 165.1 × 76.1 | 140 | 140 |

6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 140 | 140 |

6″ × 4″ | 150 × 100 | 165.1 × 114.3 | 140 | 140 |

6″ × 2″ | 150 × 50 | 168.3 × 60.3 | 140 | 140 |

8″ × 2″ | 200 × 50 | 219.1 × 60.3 | 175 | 175 |

8″ × 4″ | 200 × 100 | 219.1 × 114.3 | 175 | 175 |

8″ × 5″ | 200 × 125 | 219.1 × 139.7 | 175 | 175 |

8″ × 6″ | 200 × 150 | 219.1 × 165.1 | 175 | 175 |

- Toggle the multi-branch distribution hub: which is especially suitable for industrial systems with crisscross branches of media in different directions, and has four ports of different diameters to meet the requirements of several channel distributions of fluid.

- Compact design: Space-saving, reducing number of fittings and tee diameter for maximum layout flexibility (Ideal in equipment-intensive plant areas such as chemical plants, power stations)

- Renovation and Expansion of the System: It could be to enhance succeed water treatment, HVAC systems and other situations that need two-way expansion, expanding into pipes of different sizes.

1. Pic.2 Precise flume damper flows with four-way midline structure suitable for complex diverter requirements, reduces turbulent energy losses at the switching point and increases system energy efficiency.

2. Earth Quake resistance and leak free : The Grooved clamp connections have approvals from UL/FM, The Only type fitting with 300-500 psi furthur to the pressure, can withstand water hammer and also mechanical Vibration.

3. Quick Installation: four-point synchronous smooth groove without welding or flange alignment, reducing the construction time by more than 60%.

4. Excellent longevity: Red paint or Hot -dip galvanized surface treatment ensure long-term protection from moisture and chemical corrosion that promises the service life will also be increased by more 50%.

5. Flexible Adaptability: can support 2-1/2”×2” to 8”×6” (DN65 ~ DN200)multi-specifications, suitable for the core node of mid-size industrial pipeline network.

- Multi-directional interface protection:

- Each port is covered with PE anti-scratch film + custom EVA foam corner protectors, with plastic support frames installed at cross intersections to prevent collision deformation;

- Compression-resistant layered packaging:

- ≤6″: Single piece nested in a reinforced cardboard box with honeycomb paperboard partitions, filled with shock-absorbing bubble columns inside;

- >6“: The main body is secured with a ”cross-shaped” wooden frame and suspended within a steel-band reinforced box.

- Anti-error transportation system:

- Boxes are printed with interface size distribution diagrams and pressure rating warning labels;

- QR codes are provided for scanning to access branch flow installation guidelines, preventing incorrect pipe diameter connections.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.