HOT PRODUCTS TAGS

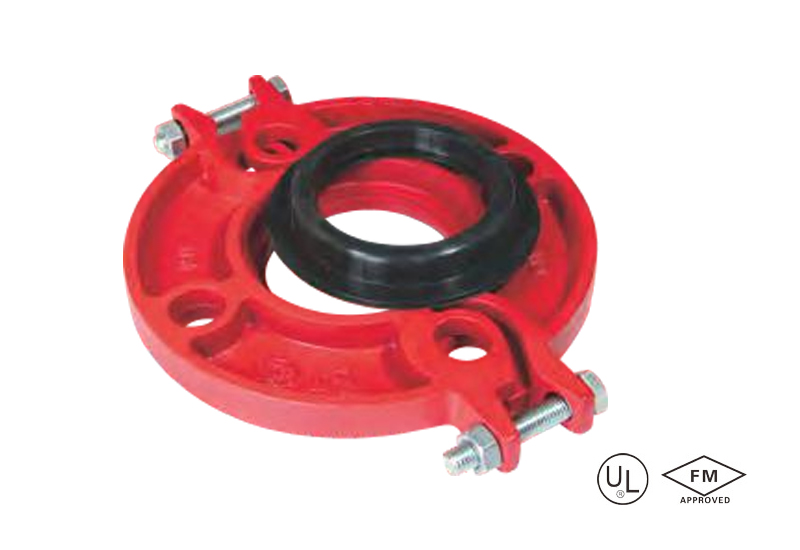

EN grooved flange two-piece (Flanged adapter)

·Standard: ANSI / UL 213 UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Bolt & nut: Carbon steel

·Gasket: EPDM, nitrile, silicone rubber, etc.

·Mating flange: EN 1092-2, PN 16, FF, RF, MF, etc

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 1-1/2″ – 14″ (PN16)

4″- 6″ (PN25)

description

EN grooved flange two-piece (Flanged adapter) is a two-piece grooved connection flange that complies with EN standards and is used as an adapter to achieve grooved connection between the pipe and the flange

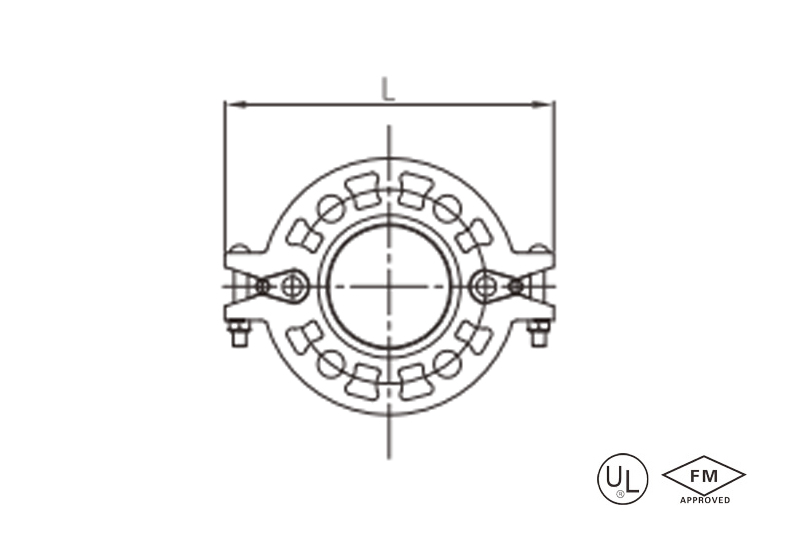

Specification

Available size

| Size | L | Assembly bolting (n – shank bolt) | Bolting for mating flange | Flanged end connection | |||

| Inch | DN | mm | mm | PCD (mm) | Bolt | ||

| 1-1/2″ | 40 | 48.3 | 195 | 2 – M10 × 50 | 110 | 4 × M16 | PN 16 |

| 2″ | 50 | 60.3 | 220 | 2 – M10 × 50 | 125 | 4 × M16 | PN 16 |

| 2-1/2″ | 65 | 76.1 | 235 | 2 – M10 × 50 | 145 | 4 × M16 | PN 16 |

| 3″ | 80 | 88.9 | 255 | 2 – M10 × 50 | 160 | 8 × M16 | PN 16 |

| 4″ | 100 | 114.3 | 279 | 2 – M10 × 50 | 180 | 8 × M16 | PN 16 |

| 5″ | 125 | 139.7 | 320 | 2 – M12 × 65 | 210 | 8 × M16 | PN 16 |

| 6″ | 150 | 165.1 | 346 | 2 – M12 × 65 | 240 | 8 × M20 | PN 16 |

| 6″ | 150 | 168.3 | 346 | 2 – M12 × 65 | 240 | 8 × M20 | PN 16 |

| 8″ | 200 | 219.1 | 414.3 | 2- M10 × 70 | 295 | 12 × M20 | PN 16 |

| 10″ | 250 | 273 | 480 | 2- M10 × 70 | 355 | 12 × M24 | PN 16 |

| 12″ | 300 | 323.9 | 530.5 | 2- M10 × 70 | 410 | 12 × M24 | PN 16 |

| 14″ | 350 | 355.6 | 580 | / | 470 | 16 × M24 | PN 16 |

| 4″ | 100 | 114.3 | 279 | 2 – M10 × 50 | 180 | 8 × M16 | PN 25 |

| 6″ | 150 | 165.1 | 346 | 2 – M12 × 65 | 240 | 8 × M20 | PN 25 |

application

- Energy and Industrial Systems:Offshore wind farm hydraulic piping (PN25 pressure rating 500 psi),Chemical plant PN16 acid-alkali medium transfer system.

- Municipal Critical Infrastructure:EU-certified fire protection piping network (UL/FM dual certification),Regional heating station flange interface retrofit (split-type quick-change design).

- Precision Industrial Applications:Pharmaceutical plant GMP pipeline maintenance (partial disassembly to prevent system contamination),Food and beverage production line sanitary connections (silicone gaskets with non-toxic certification).

- Special Maintenance Requirements:Tunnel/underground utility tunnel confined space operations,Ship engine room pipeline emergency repairs.

advantages

- European Standard Split Innovation:Two-piece structure supports single-side maintenance, reducing system downtime costs,Metric bolts (M10/M12) precisely match EN standard flanges.

- Type Smart Pressure Adaptation:PN16 across all sizes (1.5”-14”), PN25 catering to high-pressure pipe sections (4”-6”)

- Sealing Scenario Customizing: EPDM/NBR/Silicon 3 stage sealing option for -40°C to 150°C operation

- Full European Compatibility: Flange ends are EN 1092-2 and can be used with FF/RF/MF interfaces.

- Long-Term Corrosion Protection: o Hot-dip galvanized coating ≥80μm (suitable for marine environments), RAL 3000 red paint for indoor protection.

packing

- Modular packaging:Flange plates/bolt assemblies/gasket independent sealing units (moisture-proof and impact-resistant)

- Graded protection plan:

- PN16 products: EPE pearl cotton partitions + corrugated boxes (12 sets/box)

- PN25 products: Steel-reinforced wooden boxes (with embedded bolt positioning molds)

- European standard traceability markings:

- Outer boxes printed with EN 1092-2 standard number and pressure rating (PN16/PN25)

- Copies of salt spray test reports for hot-dip galvanized components

Available size

| Size | L | Assembly bolting (n – shank bolt) | Bolting for mating flange | Flanged end connection | |||

| Inch | DN | mm | mm | PCD (mm) | Bolt | ||

| 1-1/2″ | 40 | 48.3 | 195 | 2 – M10 × 50 | 110 | 4 × M16 | PN 16 |

| 2″ | 50 | 60.3 | 220 | 2 – M10 × 50 | 125 | 4 × M16 | PN 16 |

| 2-1/2″ | 65 | 76.1 | 235 | 2 – M10 × 50 | 145 | 4 × M16 | PN 16 |

| 3″ | 80 | 88.9 | 255 | 2 – M10 × 50 | 160 | 8 × M16 | PN 16 |

| 4″ | 100 | 114.3 | 279 | 2 – M10 × 50 | 180 | 8 × M16 | PN 16 |

| 5″ | 125 | 139.7 | 320 | 2 – M12 × 65 | 210 | 8 × M16 | PN 16 |

| 6″ | 150 | 165.1 | 346 | 2 – M12 × 65 | 240 | 8 × M20 | PN 16 |

| 6″ | 150 | 168.3 | 346 | 2 – M12 × 65 | 240 | 8 × M20 | PN 16 |

| 8″ | 200 | 219.1 | 414.3 | 2- M10 × 70 | 295 | 12 × M20 | PN 16 |

| 10″ | 250 | 273 | 480 | 2- M10 × 70 | 355 | 12 × M24 | PN 16 |

| 12″ | 300 | 323.9 | 530.5 | 2- M10 × 70 | 410 | 12 × M24 | PN 16 |

| 14″ | 350 | 355.6 | 580 | / | 470 | 16 × M24 | PN 16 |

| 4″ | 100 | 114.3 | 279 | 2 – M10 × 50 | 180 | 8 × M16 | PN 25 |

| 6″ | 150 | 165.1 | 346 | 2 – M12 × 65 | 240 | 8 × M20 | PN 25 |

- Energy and Industrial Systems:Offshore wind farm hydraulic piping (PN25 pressure rating 500 psi),Chemical plant PN16 acid-alkali medium transfer system.

- Municipal Critical Infrastructure:EU-certified fire protection piping network (UL/FM dual certification),Regional heating station flange interface retrofit (split-type quick-change design).

- Precision Industrial Applications:Pharmaceutical plant GMP pipeline maintenance (partial disassembly to prevent system contamination),Food and beverage production line sanitary connections (silicone gaskets with non-toxic certification).

- Special Maintenance Requirements:Tunnel/underground utility tunnel confined space operations,Ship engine room pipeline emergency repairs.

- European Standard Split Innovation:Two-piece structure supports single-side maintenance, reducing system downtime costs,Metric bolts (M10/M12) precisely match EN standard flanges.

- Type Smart Pressure Adaptation:PN16 across all sizes (1.5”-14”), PN25 catering to high-pressure pipe sections (4”-6”)

- Sealing Scenario Customizing: EPDM/NBR/Silicon 3 stage sealing option for -40°C to 150°C operation

- Full European Compatibility: Flange ends are EN 1092-2 and can be used with FF/RF/MF interfaces.

- Long-Term Corrosion Protection: o Hot-dip galvanized coating ≥80μm (suitable for marine environments), RAL 3000 red paint for indoor protection.

- Modular packaging:Flange plates/bolt assemblies/gasket independent sealing units (moisture-proof and impact-resistant)

- Graded protection plan:

- PN16 products: EPE pearl cotton partitions + corrugated boxes (12 sets/box)

- PN25 products: Steel-reinforced wooden boxes (with embedded bolt positioning molds)

- European standard traceability markings:

- Outer boxes printed with EN 1092-2 standard number and pressure rating (PN16/PN25)

- Copies of salt spray test reports for hot-dip galvanized components

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.