HOT PRODUCTS TAGS

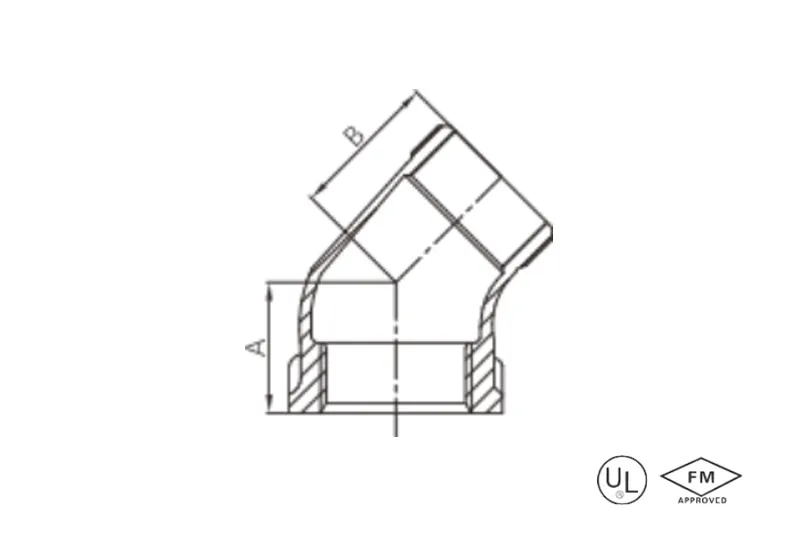

Malleable cast iron male and female 45° elbow

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1/4″-4″

description

Malleable cast iron male and female 45° elbow, with excellent material, is suitable for water, oil and gas pipelines and provides a stable connection.

Specification

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

1/4″ | 8 | 13.5 | 19 | 24 |

3/8″ | 10 | 17.2 | 20 | 25 |

1/2″ | 15 | 21.3 | 22 | 28 |

3/4″ | 20 | 26.9 | 25 | 32 |

1″ | 25 | 33.7 | 28 | 37 |

1-1/4″ | 32 | 42.4 | 33 | 43 |

1-1/2″ | 40 | 48.3 | 36 | 46 |

2″ | 50 | 60.3 | 43 | 55 |

2-1/2″ | 65 | 76.1 | 50 | 65 |

3″ | 80 | 88.9 | 55 | 76 |

4″ | 100 | 114.3 | 66 | 94 |

Note: NSF 61 certificate is available for M0601, M0602.

application

- HVAC Systems: Angled turns in chilled water pipes and direct connections to equipment.

- Industrial Equipment Layout: Low-resistance hard connections for compressor inlet and outlet pipes.

- Fire Protection System Renovation: Angled sealed connections for UL/FM-certified sprinkler systems.

- Ship Power Piping: Low-angle hard connections for pipes in confined engine room spaces.

- Building water supply systems: Leak-proof direct connections for angled branches of main pipelines.

- Energy transmission networks: 45° bends in oil and gas pipelines to reduce vortex energy loss.

- Agricultural irrigation hubs: Pressure-resistant angled hard connections between main and branch pipelines at pump stations.

- Municipal maintenance nodes: Sealed transition connections for angled maintenance ports on water supply pipelines.

advantages

- Double thread direct connection design: internal and external thread ports through the device/pipe interface.

- Fluid efficiency optimization: 45° bevel design reduces pressure loss by 35% compared to 90° elbow.

- High-pressure seal guarantee: 25bar working condition BSPT cone thread double seal zero leakage.

- All-environment corrosion resistance: Hot-dip galvanized layer resists seawater/chemical media attack.

- Dual international certifications: UL/FM fire safety and NSF 61 certification (covering M0601/M0602 models).

- Anti-vibration reinforcement: malleable cast iron base + precision thread anti-loosening.

- Wide temperature range stability: -30°C to 120°C to maintain structural integrity.

- Innovation in installation efficiency: a single piece realizes bevel steering + hard connection to reduce leakage points.

packing

- Threaded End Composite Protection: Internal threaded silicone plug + external threaded metal sleeve.

- Beveled Buffer System: High-density EPE pearl cotton molded and bonded to a 45° curved surface.

- Full-Surface Armored Wrap: Anti-rust oil coating + stretch film sealing + bubble wrap.

- Anti-misalignment Positioning: Laser-cut foam board precisely fitted into slots according to dimensions.

- Angled flow direction indicator: Red arrow printed on the outer box indicating the 45° fluid flow direction.

- Certification management: NSF-certified models are labeled separately and accompanied by a certificate.

- Load-bearing grading scheme: ≤1“ uses reinforced cardboard boxes / ≥1.25” uses fumigated wooden boxes.

- Smart traceability system: Laser anti-counterfeiting codes on the box are linked to production batch data.

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

1/4″ | 8 | 13.5 | 19 | 24 |

3/8″ | 10 | 17.2 | 20 | 25 |

1/2″ | 15 | 21.3 | 22 | 28 |

3/4″ | 20 | 26.9 | 25 | 32 |

1″ | 25 | 33.7 | 28 | 37 |

1-1/4″ | 32 | 42.4 | 33 | 43 |

1-1/2″ | 40 | 48.3 | 36 | 46 |

2″ | 50 | 60.3 | 43 | 55 |

2-1/2″ | 65 | 76.1 | 50 | 65 |

3″ | 80 | 88.9 | 55 | 76 |

4″ | 100 | 114.3 | 66 | 94 |

Note: NSF 61 certificate is available for M0601, M0602.

- HVAC Systems: Angled turns in chilled water pipes and direct connections to equipment.

- Industrial Equipment Layout: Low-resistance hard connections for compressor inlet and outlet pipes.

- Fire Protection System Renovation: Angled sealed connections for UL/FM-certified sprinkler systems.

- Ship Power Piping: Low-angle hard connections for pipes in confined engine room spaces.

- Building water supply systems: Leak-proof direct connections for angled branches of main pipelines.

- Energy transmission networks: 45° bends in oil and gas pipelines to reduce vortex energy loss.

- Agricultural irrigation hubs: Pressure-resistant angled hard connections between main and branch pipelines at pump stations.

- Municipal maintenance nodes: Sealed transition connections for angled maintenance ports on water supply pipelines.

- Double thread direct connection design: internal and external thread ports through the device/pipe interface.

- Fluid efficiency optimization: 45° bevel design reduces pressure loss by 35% compared to 90° elbow.

- High-pressure seal guarantee: 25bar working condition BSPT cone thread double seal zero leakage.

- All-environment corrosion resistance: Hot-dip galvanized layer resists seawater/chemical media attack.

- Dual international certifications: UL/FM fire safety and NSF 61 certification (covering M0601/M0602 models).

- Anti-vibration reinforcement: malleable cast iron base + precision thread anti-loosening.

- Wide temperature range stability: -30°C to 120°C to maintain structural integrity.

- Innovation in installation efficiency: a single piece realizes bevel steering + hard connection to reduce leakage points.

- Threaded End Composite Protection: Internal threaded silicone plug + external threaded metal sleeve.

- Beveled Buffer System: High-density EPE pearl cotton molded and bonded to a 45° curved surface.

- Full-Surface Armored Wrap: Anti-rust oil coating + stretch film sealing + bubble wrap.

- Anti-misalignment Positioning: Laser-cut foam board precisely fitted into slots according to dimensions.

- Angled flow direction indicator: Red arrow printed on the outer box indicating the 45° fluid flow direction.

- Certification management: NSF-certified models are labeled separately and accompanied by a certificate.

- Load-bearing grading scheme: ≤1“ uses reinforced cardboard boxes / ≥1.25” uses fumigated wooden boxes.

- Smart traceability system: Laser anti-counterfeiting codes on the box are linked to production batch data.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.