HOT PRODUCTS TAGS

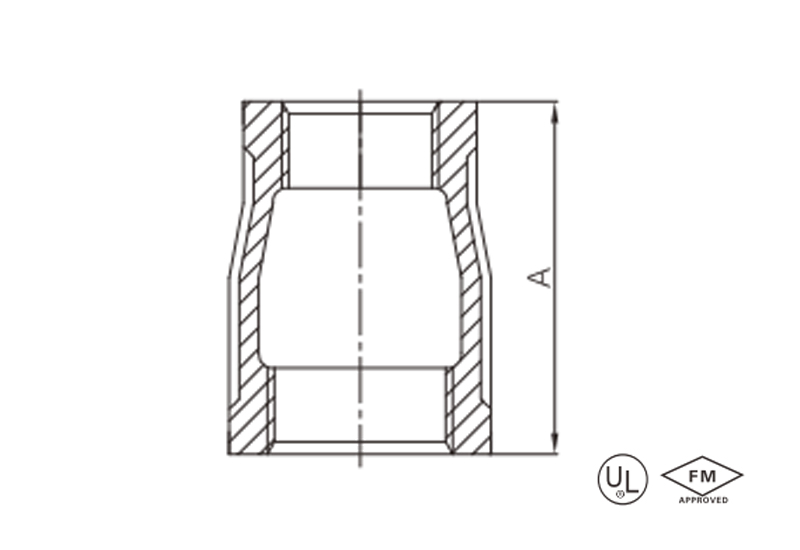

Malleable iron reducing coupling (Reducing socket / Reducer)

·Standard: ANSI/ASME B16.3

UL/FM

·Material: Malleable iron ASTM A197

·Thread: NPT

·W. pressure: Class 150, 300 psi (-29°C to 66°C)

Class 300, 1000 / 1500 / 2000 psi

(-29°C to 66°C)

·Surface: Black iron / hot dip galvanized

·Size Range: 1/2″ x 1/4″ —4″ x 3″ (Class 150)

3/8” x 1/4” —4” x 3” (Class 300)

description

Malleable iron reducing coupling ensures precise diameter adaptation, leak-proof sealing, pressure-corrosion resistance, and easy installation.

Specification

Available size

SIZE | A | ||

INCH | DN | MM | MM |

1/2″ x 1/4″ | 15 x 8 | 21.3 x 13.7 | 31.8 |

1/2″ x 3/8″ | 15 x 10 | 21.3 x 17.1 | 31.8 |

3/4″ x 1/4″ | 20 x 8 | 26.7 x 13.7 | 36.6 |

3/4″ x 3/8″ | 20 x 10 | 26.7 x 17.1 | 36.6 |

1″ x 3/8″ | 25 x 10 | 33.4 x 17.1 | 42.9 |

1″ x 1/2″ | 25 x 15 | 33.4 x 21.3 | 42.9 |

1″ x 3/4″ | 25 x 20 | 33.4 x 26.7 | 42.9 |

1-1/4″ x 1/2″ | 32 x 15 | 42.2 x 21.3 | 52.3 |

1-1/4″ x 3/4″ | 32 x 20 | 42.2 x 26.7 | 52.3 |

1-1/4″ x 1″ | 32 x 25 | 42.2 x 33.4 | 52.3 |

1-1/2″ x 1/2″ | 40 x 15 | 48.3 x 21.3 | 58.7 |

1-1/2″ x 3/4″ | 40 x 20 | 48.3 x 26.7 | 58.7 |

1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.4 | 58.7 |

1-1/2″ x 1-1/4″ | 40 x 32 | 48.3 x 42.2 | 58.7 |

2″ x 1/2″ | 50 x 15 | 60.3 x 21.3 | 71.4 |

2″ x 3/4″ | 50 x 20 | 60.3 x 26.7 | 71.4 |

2″ x 1″ | 50 x 25 | 60.3 x 33.4 | 71.4 |

2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.2 | 71.4 |

2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 71.4 |

2-1/2″ x 1-1/2″ | 65 x 40 | 73.0 x 48.3 | 82.6 |

2-1/2″ x 2″ | 65 x 50 | 73.0 x 60.3 | 82.6 |

3″ x 1-1/2″ | 80 x 40 | 88.9 x 48.3 | 93.7 |

3″ x 2″ | 80 x 50 | 88.9 x 60.3 | 93.7 |

3″ x 2-1/2″ | 80 x 65 | 88.9 x 73.0 | 93.7 |

4″ x 2″ | 100 x 50 | 114.3 x 60.3 | 111.3 |

4″ x 3″ | 100 x 80 | 114.3 x 88.9 | 111.3 |

3/8” x 1/4” | 10 x 8 | 17.1 x 13.7 | 36.6 |

1/2” x 1/4” | 15 x 8 | 21.3 x 13.7 | 42.9 |

1/2” x 3/8” | 15 x 10 | 21.3 x 17.1 | 42.9 |

3/4” x 1/4” | 20 x 8 | 26.7 x 13.7 | 44.5 |

3/4” x 3/8” | 20 x 10 | 26.7 x 17.1 | 44.5 |

3/4” x 1/2” | 20 x 15 | 26.7 x 21.3 | 44.5 |

3/4” x 1/2” | 20 x 15 | 26.7 x 21.3 | 44.5 |

1” x 3/8” | 25 x 10 | 33.4 x 17.1 | 50.8 |

1” x 1/2” | 25 x 15 | 33.4 x 21.3 | 50.8 |

1” x 3/4” | 25 x 20 | 33.4 x 26.7 | 50.8 |

1-1/4” x 1/2” | 32 x 15 | 42.2 x 21.3 | 60.5 |

1-1/4” x 3/4” | 32 x 20 | 42.2 x 26.7 | 60.5 |

1-1/4” x 1” | 32 x 25 | 42.2 x 33.4 | 60.5 |

1-1/2” x 1/2” | 40 x 15 | 48.3 x 21.3 | 68.3 |

1-1/2” x 3/4” | 40 x 20 | 48.3 x 26.7 | 68.3 |

1-1/2” x 1” | 40 x 25 | 48.3 x 33.4 | 68.3 |

1-1/2” x 1-1/4” | 40 x 32 | 48.3 x 42.2 | 68.3 |

2” x 1/2” | 50 x 15 | 60.3 x 21.3 | 81 |

2” x 3/4” | 50 x 20 | 60.3 x 26.7 | 81 |

2” x 1” | 50 x 25 | 60.3 x 33.4 | 81 |

2” x 1-1/4” | 50 x 32 | 60.3 x 42.2 | 81 |

2” x 1-1/2” | 50 x 40 | 60.3 x 48.3 | 81 |

2-1/2” x 1-1/2” | 65 x 40 | 73.0 x 48.3 | 81 |

2-1/2” x 2” | 65 x 50 | 73.0 x 60.3 | 93.7 |

3” x 2” | 80 x 50 | 88.9 x 60.3 | 103.1 |

3” x 2-1/2” | 80 x 65 | 88.9 x 73.0 | 103.1 |

4” x 3” | 100 x 80 | 114.3 x 88.9 | 110 |

application

- Equipment Interface Modification Project: Connecting equipment ports of different specifications to the main pipeline.

- Pipeline System Upgrade and Expansion: Connecting new and old mixed-diameter water supply/gas supply pipelines.

- Industrial Equipment Upgrade Support: Matching existing pipeline system interfaces to upgraded equipment.

- Ship Pipeline Modification Project: Connecting engine room equipment to deck pipelines with different diameters.

- Agricultural Irrigation System Optimization: Converting diameter differences between irrigation pipes made of different materials.

- Laboratory Precision Instrument Connections: Transition fittings between micro-pipes and standard pipes.

- Energy Transmission Pipeline Adaptation: Sealed connections between pipes of different thicknesses in oil and gas pipelines.

- Fire Protection System Emergency Repairs: Rapid replacement of damaged pipe sections with different diameter connections.

advantages

- Dual-diameter precision fit: Flexibly connects any two pipe specifications.

- High-pressure dynamic sealing: Maintains zero leakage at the interface under extreme conditions.

- Full-flow corrosion protection: Galvanized coating resists bidirectional corrosion from chemical media.

- Ultra-wide size coverage: Compatible with micro-precision tubes to large industrial pipes.

- Thermal expansion and contraction resistance design: Maintains sealing stability under extreme temperature changes.

- Second-level installation efficiency: Quick assembly achieved through a snap-fit structure.

- Optimized for vibration conditions: Threaded locking mechanism prevents interface loosening.

- Lifetime maintenance-free commitment: Special processes significantly extend service life.

packing

- Dual-interface independent protection: Customized PE protective covers for collision prevention at different diameter ends.

- Full-body encapsulation: Double-layered packaging with bubble column bags and anti-rust paper.

- Intelligent specification-based packing: Honeycomb cardboard partitions for size-based classification and positioning.

- Different diameter identification system: dual-color printing on the outer box corresponding to the diameter parameters.

- Load-bearing grading scheme: small-sized paper boxes/large-sized steel frame wooden boxes for separate packaging.

- Marine moisture-proof treatment: built-in desiccant + waterproof membrane sealing.

- Full-process traceability management: laser engraving + intelligent QR code traceability.

- Warehouse stacking optimization: box body groove structure supports three-dimensional dense storage.

Available size

SIZE | A | ||

INCH | DN | MM | MM |

1/2″ x 1/4″ | 15 x 8 | 21.3 x 13.7 | 31.8 |

1/2″ x 3/8″ | 15 x 10 | 21.3 x 17.1 | 31.8 |

3/4″ x 1/4″ | 20 x 8 | 26.7 x 13.7 | 36.6 |

3/4″ x 3/8″ | 20 x 10 | 26.7 x 17.1 | 36.6 |

1″ x 3/8″ | 25 x 10 | 33.4 x 17.1 | 42.9 |

1″ x 1/2″ | 25 x 15 | 33.4 x 21.3 | 42.9 |

1″ x 3/4″ | 25 x 20 | 33.4 x 26.7 | 42.9 |

1-1/4″ x 1/2″ | 32 x 15 | 42.2 x 21.3 | 52.3 |

1-1/4″ x 3/4″ | 32 x 20 | 42.2 x 26.7 | 52.3 |

1-1/4″ x 1″ | 32 x 25 | 42.2 x 33.4 | 52.3 |

1-1/2″ x 1/2″ | 40 x 15 | 48.3 x 21.3 | 58.7 |

1-1/2″ x 3/4″ | 40 x 20 | 48.3 x 26.7 | 58.7 |

1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.4 | 58.7 |

1-1/2″ x 1-1/4″ | 40 x 32 | 48.3 x 42.2 | 58.7 |

2″ x 1/2″ | 50 x 15 | 60.3 x 21.3 | 71.4 |

2″ x 3/4″ | 50 x 20 | 60.3 x 26.7 | 71.4 |

2″ x 1″ | 50 x 25 | 60.3 x 33.4 | 71.4 |

2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.2 | 71.4 |

2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 71.4 |

2-1/2″ x 1-1/2″ | 65 x 40 | 73.0 x 48.3 | 82.6 |

2-1/2″ x 2″ | 65 x 50 | 73.0 x 60.3 | 82.6 |

3″ x 1-1/2″ | 80 x 40 | 88.9 x 48.3 | 93.7 |

3″ x 2″ | 80 x 50 | 88.9 x 60.3 | 93.7 |

3″ x 2-1/2″ | 80 x 65 | 88.9 x 73.0 | 93.7 |

4″ x 2″ | 100 x 50 | 114.3 x 60.3 | 111.3 |

4″ x 3″ | 100 x 80 | 114.3 x 88.9 | 111.3 |

3/8” x 1/4” | 10 x 8 | 17.1 x 13.7 | 36.6 |

1/2” x 1/4” | 15 x 8 | 21.3 x 13.7 | 42.9 |

1/2” x 3/8” | 15 x 10 | 21.3 x 17.1 | 42.9 |

3/4” x 1/4” | 20 x 8 | 26.7 x 13.7 | 44.5 |

3/4” x 3/8” | 20 x 10 | 26.7 x 17.1 | 44.5 |

3/4” x 1/2” | 20 x 15 | 26.7 x 21.3 | 44.5 |

3/4” x 1/2” | 20 x 15 | 26.7 x 21.3 | 44.5 |

1” x 3/8” | 25 x 10 | 33.4 x 17.1 | 50.8 |

1” x 1/2” | 25 x 15 | 33.4 x 21.3 | 50.8 |

1” x 3/4” | 25 x 20 | 33.4 x 26.7 | 50.8 |

1-1/4” x 1/2” | 32 x 15 | 42.2 x 21.3 | 60.5 |

1-1/4” x 3/4” | 32 x 20 | 42.2 x 26.7 | 60.5 |

1-1/4” x 1” | 32 x 25 | 42.2 x 33.4 | 60.5 |

1-1/2” x 1/2” | 40 x 15 | 48.3 x 21.3 | 68.3 |

1-1/2” x 3/4” | 40 x 20 | 48.3 x 26.7 | 68.3 |

1-1/2” x 1” | 40 x 25 | 48.3 x 33.4 | 68.3 |

1-1/2” x 1-1/4” | 40 x 32 | 48.3 x 42.2 | 68.3 |

2” x 1/2” | 50 x 15 | 60.3 x 21.3 | 81 |

2” x 3/4” | 50 x 20 | 60.3 x 26.7 | 81 |

2” x 1” | 50 x 25 | 60.3 x 33.4 | 81 |

2” x 1-1/4” | 50 x 32 | 60.3 x 42.2 | 81 |

2” x 1-1/2” | 50 x 40 | 60.3 x 48.3 | 81 |

2-1/2” x 1-1/2” | 65 x 40 | 73.0 x 48.3 | 81 |

2-1/2” x 2” | 65 x 50 | 73.0 x 60.3 | 93.7 |

3” x 2” | 80 x 50 | 88.9 x 60.3 | 103.1 |

3” x 2-1/2” | 80 x 65 | 88.9 x 73.0 | 103.1 |

4” x 3” | 100 x 80 | 114.3 x 88.9 | 110 |

- Equipment Interface Modification Project: Connecting equipment ports of different specifications to the main pipeline.

- Pipeline System Upgrade and Expansion: Connecting new and old mixed-diameter water supply/gas supply pipelines.

- Industrial Equipment Upgrade Support: Matching existing pipeline system interfaces to upgraded equipment.

- Ship Pipeline Modification Project: Connecting engine room equipment to deck pipelines with different diameters.

- Agricultural Irrigation System Optimization: Converting diameter differences between irrigation pipes made of different materials.

- Laboratory Precision Instrument Connections: Transition fittings between micro-pipes and standard pipes.

- Energy Transmission Pipeline Adaptation: Sealed connections between pipes of different thicknesses in oil and gas pipelines.

- Fire Protection System Emergency Repairs: Rapid replacement of damaged pipe sections with different diameter connections.

- Dual-diameter precision fit: Flexibly connects any two pipe specifications.

- High-pressure dynamic sealing: Maintains zero leakage at the interface under extreme conditions.

- Full-flow corrosion protection: Galvanized coating resists bidirectional corrosion from chemical media.

- Ultra-wide size coverage: Compatible with micro-precision tubes to large industrial pipes.

- Thermal expansion and contraction resistance design: Maintains sealing stability under extreme temperature changes.

- Second-level installation efficiency: Quick assembly achieved through a snap-fit structure.

- Optimized for vibration conditions: Threaded locking mechanism prevents interface loosening.

- Lifetime maintenance-free commitment: Special processes significantly extend service life.

- Dual-interface independent protection: Customized PE protective covers for collision prevention at different diameter ends.

- Full-body encapsulation: Double-layered packaging with bubble column bags and anti-rust paper.

- Intelligent specification-based packing: Honeycomb cardboard partitions for size-based classification and positioning.

- Different diameter identification system: dual-color printing on the outer box corresponding to the diameter parameters.

- Load-bearing grading scheme: small-sized paper boxes/large-sized steel frame wooden boxes for separate packaging.

- Marine moisture-proof treatment: built-in desiccant + waterproof membrane sealing.

- Full-process traceability management: laser engraving + intelligent QR code traceability.

- Warehouse stacking optimization: box body groove structure supports three-dimensional dense storage.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.