HOT PRODUCTS TAGS

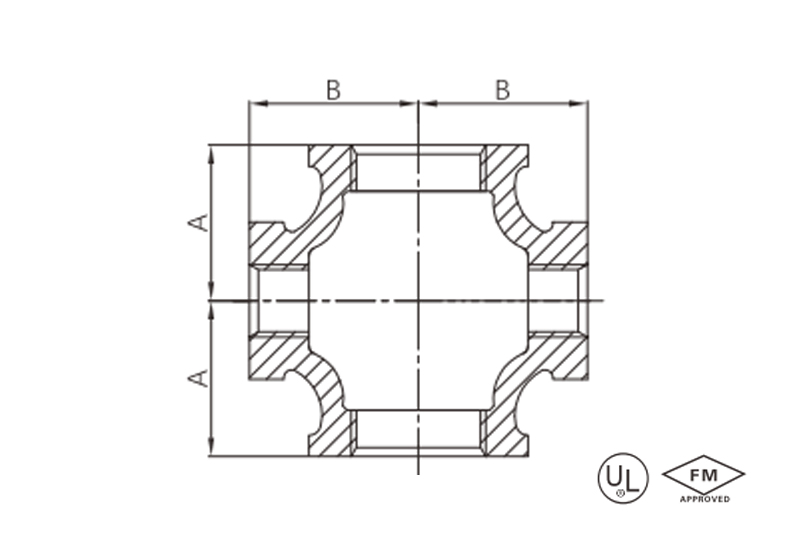

Malleable iron reducing cross

·Standard: ANSI/ASME B16.3

UL/FM

·Material: Malleable iron ASTM A197

·Thread: NPT

·W. pressure: Class 150, 300 psi (-29°C to 66°C)

·Surface: Black iron / hot dip galvanized

·Size Range: 3/4″ x 1/2″ —4″ x 3″ (Class 150)

description

Malleable iron reducing cross enables flexible multi-diameter adaptation, offers high pressure resistance, corrosion resistance, and precise, efficient flow division.

Specification

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

3/4″ x 1/2″ | 20 x 15 | 26.7 x 21.3 | 30.5 | 31 |

1″ x 1/2″ | 25 x 15 | 33.4 x 21.3 | 32 | 35.5 |

1″ x 3/4″ | 25 x 20 | 33.4 x 26.7 | 34.8 | 36.8 |

1-1/4″ x 3/4″ | 32 x 20 | 42.2 x 26.7 | 36.8 | 41.2 |

1-1/4″ x 1″ | 32 x 25 | 42.2 x 33.4 | 40.1 | 42.4 |

1-1/2″ x 3/4″ | 40 x 20 | 48.3 x 26.7 | 38.6 | 44.5 |

1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.4 | 41.9 | 45.7 |

1-1/2″ x 1-1/4″ | 40 x 32 | 48.3 x 42.2 | 46.2 | 47.8 |

2″ x 3/4″ | 50 x 20 | 60.3 x 26.7 | 40.6 | 50 |

2″ x 1″ | 50 x 25 | 60.3 x 33.4 | 43.9 | 51.3 |

2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.2 | 48.3 | 53.3 |

2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 51.3 | 54.9 |

2-1/2″ x 2″ | 65 x 50 | 73.0 x 60.3 | 60.7 | 66 |

3″ x 1″ | 80 x 25 | 88.9 x 33.4 | 49 | 66 |

3″ x 1-1/4″ | 80 x 32 | 88.9 x 42.2 | 53 | 68 |

3″ x 1-1/2″ | 80 x 40 | 88.9 x 48.3 | 56.5 | 69.5 |

3″ x 2″ | 80 x 50 | 88.9 x 60.3 | 64 | 73.4 |

4″ x 3″ | 100 x 80 | 114.3 x 88.9 | 82 | 90 |

application

- Industrial multi-level distribution network: The main pipeline is simultaneously diverted to branch systems of different diameters.

- Regional heating hub renovation: The main heating pipeline is distributed to secondary networks of mixed new and old specifications.

- Chemical reaction tower cluster: The main raw material pipeline is differentially distributed to reaction devices of multiple specifications.

- Ship comprehensive pipeline upgrade: The main ballast pipeline is connected to branch pipelines of different diameters for cabin water supply.

- Data center liquid cooling system: The cooling main pipeline is diverted to multiple generations of server cabinet interfaces.

- Mining slurry processing center: The main pipeline distributes to branch pipelines for processing slurry of different concentrations.

- Fire protection system expansion project: The main pipeline connects to a spray network with mixed new and old specifications.

advantages

- Multiple diameter flexible adaptation: 4-way variable diameter design, which meets the requirements of complex pipeline network.

- Equal pressure distribution in four directions: the design of channels improves GIS to realize stable and balanced pressure of each outlet.

- Reinforcement of cross structure: Reinforced rib design, which can resist high pressure fluctuation and physical impacts.

- Internal and external hot dip galvanizing provides complete-flow corrosion protection.

- Zero-leakage sealing solution: high precision threaded interfaces seal with zero leaks over the long life of the product.

- Wide temperature range stability – supports material strength and sealing capability with even the most extreme temperatures.

- Modular fast assembly: Regular interface design, which is conducive to the multiple pipelines installation Increased time between maintenance: through preventative testing of data-holding equipment.

packing

- Multi-interface 3D protection: Custom EPS molded cover for four-way reducer joints.

- Threaded graded protective cover system: Specialized screw caps match different thread sizes for protection.

- Layered seismic isolation packaging: Honeycomb cardboard partitions secure items to prevent shifting and collision.

- Smart outer box labeling: Printed flow arrows and reducer size reference charts.

- Heavy-duty reinforced wooden boxes: Steel frame structure enhances compression strength for large-sized products.

- Strict transportation certification: Meets international logistics safety testing standards.

- Full-process traceability management: Tube body laser coding + outer box QR code traceability.

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

3/4″ x 1/2″ | 20 x 15 | 26.7 x 21.3 | 30.5 | 31 |

1″ x 1/2″ | 25 x 15 | 33.4 x 21.3 | 32 | 35.5 |

1″ x 3/4″ | 25 x 20 | 33.4 x 26.7 | 34.8 | 36.8 |

1-1/4″ x 3/4″ | 32 x 20 | 42.2 x 26.7 | 36.8 | 41.2 |

1-1/4″ x 1″ | 32 x 25 | 42.2 x 33.4 | 40.1 | 42.4 |

1-1/2″ x 3/4″ | 40 x 20 | 48.3 x 26.7 | 38.6 | 44.5 |

1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.4 | 41.9 | 45.7 |

1-1/2″ x 1-1/4″ | 40 x 32 | 48.3 x 42.2 | 46.2 | 47.8 |

2″ x 3/4″ | 50 x 20 | 60.3 x 26.7 | 40.6 | 50 |

2″ x 1″ | 50 x 25 | 60.3 x 33.4 | 43.9 | 51.3 |

2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.2 | 48.3 | 53.3 |

2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 51.3 | 54.9 |

2-1/2″ x 2″ | 65 x 50 | 73.0 x 60.3 | 60.7 | 66 |

3″ x 1″ | 80 x 25 | 88.9 x 33.4 | 49 | 66 |

3″ x 1-1/4″ | 80 x 32 | 88.9 x 42.2 | 53 | 68 |

3″ x 1-1/2″ | 80 x 40 | 88.9 x 48.3 | 56.5 | 69.5 |

3″ x 2″ | 80 x 50 | 88.9 x 60.3 | 64 | 73.4 |

4″ x 3″ | 100 x 80 | 114.3 x 88.9 | 82 | 90 |

- Industrial multi-level distribution network: The main pipeline is simultaneously diverted to branch systems of different diameters.

- Regional heating hub renovation: The main heating pipeline is distributed to secondary networks of mixed new and old specifications.

- Chemical reaction tower cluster: The main raw material pipeline is differentially distributed to reaction devices of multiple specifications.

- Ship comprehensive pipeline upgrade: The main ballast pipeline is connected to branch pipelines of different diameters for cabin water supply.

- Data center liquid cooling system: The cooling main pipeline is diverted to multiple generations of server cabinet interfaces.

- Mining slurry processing center: The main pipeline distributes to branch pipelines for processing slurry of different concentrations.

- Fire protection system expansion project: The main pipeline connects to a spray network with mixed new and old specifications.

- Multiple diameter flexible adaptation: 4-way variable diameter design, which meets the requirements of complex pipeline network.

- Equal pressure distribution in four directions: the design of channels improves GIS to realize stable and balanced pressure of each outlet.

- Reinforcement of cross structure: Reinforced rib design, which can resist high pressure fluctuation and physical impacts.

- Internal and external hot dip galvanizing provides complete-flow corrosion protection.

- Zero-leakage sealing solution: high precision threaded interfaces seal with zero leaks over the long life of the product.

- Wide temperature range stability – supports material strength and sealing capability with even the most extreme temperatures.

- Modular fast assembly: Regular interface design, which is conducive to the multiple pipelines installation Increased time between maintenance: through preventative testing of data-holding equipment.

- Multi-interface 3D protection: Custom EPS molded cover for four-way reducer joints.

- Threaded graded protective cover system: Specialized screw caps match different thread sizes for protection.

- Layered seismic isolation packaging: Honeycomb cardboard partitions secure items to prevent shifting and collision.

- Smart outer box labeling: Printed flow arrows and reducer size reference charts.

- Heavy-duty reinforced wooden boxes: Steel frame structure enhances compression strength for large-sized products.

- Strict transportation certification: Meets international logistics safety testing standards.

- Full-process traceability management: Tube body laser coding + outer box QR code traceability.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.