HOT PRODUCTS TAGS

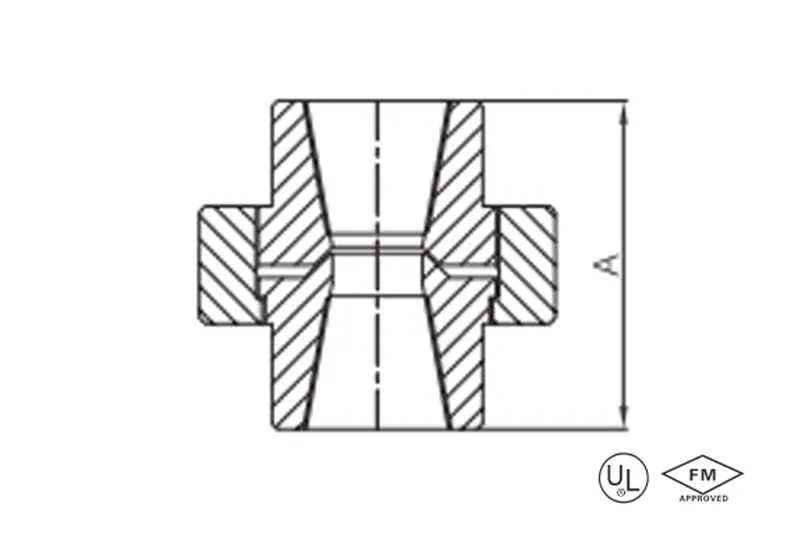

Malleable iron union (Ball-to-cone / ball-to-ball joint)

·Standard: ASME B16.39

UL/FM

·Material: Malleable iron ASTM A197

·Seat: Brass insert ring

·Thread: NPT

·W. pressure: Class 150, 300 psi (-29°C to 66°C)

Class 300, 600 psi (-29°C to 66°C)

·Surface: Black iron / hot dip galvanized

·Size Range: 1/4″ —6″ (Class 150)

1/8″ —4″ (Class 300)

description

Malleable iron union (Ball-to-cone/ball-to-ball joint) is a kind of malleable cast iron pipe fitting. Through the mating structure of balls and cones or balls and balls, it realizes the detachable connection of pipes.

Specification

Available size

Size | A (Min) | Joint type | ||

Inch | DN | mm | mm |

|

1/4″ | 8 | 13.7 | 36.5 | Ball-to-cone / ball-to-ball |

3/8″ | 10 | 17.1 | 41.0 | Ball-to-cone / ball-to-ball |

1/2″ | 15 | 21.3 | 43.5 | Ball-to-cone / ball-to-ball |

3/4″ | 20 | 26.7 | 49.5 | Ball-to-cone / ball-to-ball |

1″ | 25 | 33.4 | 52.5 | Ball-to-cone / ball-to-ball |

1-1/4″ | 32 | 42.2 | 57.5 | Ball-to-cone / ball-to-ball |

1-1/2″ | 40 | 48.3 | 61.0 | Ball-to-cone / ball-to-ball |

2″ | 50 | 60.3 | 70.0 | Ball-to-cone / ball-to-ball |

2-1/2″ | 65 | 73.0 | 82.0 | Ball-to-cone / ball-to-ball |

3″ | 80 | 88.9 | 89.0 | Ball-to-cone / ball-to-ball |

4″ | 100 | 114.3 | 98.0 | Ball-to-cone / ball-to-ball |

6″ | 150 | 168.3 | 132.0 | Ball-to-cone / ball-to-ball |

1/8” | 6 | 10.3 | 32.0 | Ball-to-cone / ball-to-ball |

1/4” | 8 | 13.7 | 39.5 | Ball-to-cone / ball-to-ball |

3/8” | 10 | 17.1 | 43.5 | Ball-to-cone / ball-to-ball |

1/2” | 15 | 21.3 | 46.0 | Ball-to-cone / ball-to-ball |

3/4” | 20 | 26.7 | 54.0 | Ball-to-cone / ball-to-ball |

1” | 25 | 33.4 | 58.5 | Ball-to-cone / ball-to-ball |

1-1/4” | 32 | 42.2 | 67.5 | Ball-to-cone / ball-to-ball |

1-1/2” | 40 | 48.3 | 72.5 | Ball-to-cone / ball-to-ball |

2” | 50 | 60.3 | 82.0 | Ball-to-cone / ball-to-ball |

2-1/2” | 65 | 73.0 | 84.5 | Ball-to-cone / ball-to-ball |

3” | 80 | 88.9 | 104.0 | Ball-to-cone / ball-to-ball |

4” | 100 | 114.3 | 113.5 | Ball-to-cone / ball-to-ball |

application

- Quick-release piping for equipment: Connection interfaces for industrial equipment and conveying pipelines that require frequent disassembly.

- Regular calibration system for instruments: Connections for instruments such as pressure gauges and flow meters that require regular disassembly and inspection.

- Removable piping for ships: Anti-vibration separable connections between engine room equipment and deck pipelines.

- Water treatment filter cartridge replacement: Quick-release cleaning interfaces between filter housings and pipelines.

- Energy station valve maintenance: Connection points for valves in oil and gas pipelines that require frequent maintenance.

- Laboratory modular system: Quick-release connections between laboratory equipment and gas supply pipelines.

- Firefighting equipment emergency deployment: Quick-release connections between fire hoses and main pipelines.

- Agricultural irrigation seasonal assembly: Pipeline connections for irrigation equipment that requires seasonal installation and disassembly.

advantages

- Ball-cone double seal structure: The combination of spherical and conical seals ensures a leak-free connection.

- Quick-release design: Manual operation enables pipeline connection and disconnection in seconds.

- Vibration-resistant self-adjusting: The spherical structure automatically compensates for pipeline vibration displacement.

- Corrosion-Resistant in All Environments: Galvanized coating + brass seal ring resist chemical medium corrosion.

- Wide Temperature Adaptability: Maintains seal material elasticity in extreme cold and high-temperature environments.

- Reusable Performance: Special structure supports over 1,000 disassemblies without failure.

- Multi-Angle Deviation Compensation: Spherical structure allows for ≤5° pipe angle deviation.

- Lifetime Maintenance-Free Commitment: Optimized process significantly extends service life cycle.

packing

- Spherical-specific protective cover: Custom silicone cover fits spherical structure to prevent scratches.

- Double protection for threaded ends: Screw cap + foam ring composite protection for precision threads.

- Live joint component positioning: Embedded foam bracket secures separate components.

- Anti-misassembly Marking: Left and right connectors distinguished by color codes + anti-reverse insertion design.

- Smart Size-Specific Packaging: Honeycomb cardboard compartments for size-specific organization and fixation.

- Visualized Operation Guide: Quick installation diagrams printed on the outer box.

- Full-Process Traceability System: Component laser coding + outer box QR code traceability.

- Anti-misoperation Locking Design: Transport locks prevent accidental separation of the quick-release connector.

Available size

Size | A (Min) | Joint type | ||

Inch | DN | mm | mm |

|

1/4″ | 8 | 13.7 | 36.5 | Ball-to-cone / ball-to-ball |

3/8″ | 10 | 17.1 | 41.0 | Ball-to-cone / ball-to-ball |

1/2″ | 15 | 21.3 | 43.5 | Ball-to-cone / ball-to-ball |

3/4″ | 20 | 26.7 | 49.5 | Ball-to-cone / ball-to-ball |

1″ | 25 | 33.4 | 52.5 | Ball-to-cone / ball-to-ball |

1-1/4″ | 32 | 42.2 | 57.5 | Ball-to-cone / ball-to-ball |

1-1/2″ | 40 | 48.3 | 61.0 | Ball-to-cone / ball-to-ball |

2″ | 50 | 60.3 | 70.0 | Ball-to-cone / ball-to-ball |

2-1/2″ | 65 | 73.0 | 82.0 | Ball-to-cone / ball-to-ball |

3″ | 80 | 88.9 | 89.0 | Ball-to-cone / ball-to-ball |

4″ | 100 | 114.3 | 98.0 | Ball-to-cone / ball-to-ball |

6″ | 150 | 168.3 | 132.0 | Ball-to-cone / ball-to-ball |

1/8” | 6 | 10.3 | 32.0 | Ball-to-cone / ball-to-ball |

1/4” | 8 | 13.7 | 39.5 | Ball-to-cone / ball-to-ball |

3/8” | 10 | 17.1 | 43.5 | Ball-to-cone / ball-to-ball |

1/2” | 15 | 21.3 | 46.0 | Ball-to-cone / ball-to-ball |

3/4” | 20 | 26.7 | 54.0 | Ball-to-cone / ball-to-ball |

1” | 25 | 33.4 | 58.5 | Ball-to-cone / ball-to-ball |

1-1/4” | 32 | 42.2 | 67.5 | Ball-to-cone / ball-to-ball |

1-1/2” | 40 | 48.3 | 72.5 | Ball-to-cone / ball-to-ball |

2” | 50 | 60.3 | 82.0 | Ball-to-cone / ball-to-ball |

2-1/2” | 65 | 73.0 | 84.5 | Ball-to-cone / ball-to-ball |

3” | 80 | 88.9 | 104.0 | Ball-to-cone / ball-to-ball |

4” | 100 | 114.3 | 113.5 | Ball-to-cone / ball-to-ball |

- Quick-release piping for equipment: Connection interfaces for industrial equipment and conveying pipelines that require frequent disassembly.

- Regular calibration system for instruments: Connections for instruments such as pressure gauges and flow meters that require regular disassembly and inspection.

- Removable piping for ships: Anti-vibration separable connections between engine room equipment and deck pipelines.

- Water treatment filter cartridge replacement: Quick-release cleaning interfaces between filter housings and pipelines.

- Energy station valve maintenance: Connection points for valves in oil and gas pipelines that require frequent maintenance.

- Laboratory modular system: Quick-release connections between laboratory equipment and gas supply pipelines.

- Firefighting equipment emergency deployment: Quick-release connections between fire hoses and main pipelines.

- Agricultural irrigation seasonal assembly: Pipeline connections for irrigation equipment that requires seasonal installation and disassembly.

- Ball-cone double seal structure: The combination of spherical and conical seals ensures a leak-free connection.

- Quick-release design: Manual operation enables pipeline connection and disconnection in seconds.

- Vibration-resistant self-adjusting: The spherical structure automatically compensates for pipeline vibration displacement.

- Corrosion-Resistant in All Environments: Galvanized coating + brass seal ring resist chemical medium corrosion.

- Wide Temperature Adaptability: Maintains seal material elasticity in extreme cold and high-temperature environments.

- Reusable Performance: Special structure supports over 1,000 disassemblies without failure.

- Multi-Angle Deviation Compensation: Spherical structure allows for ≤5° pipe angle deviation.

- Lifetime Maintenance-Free Commitment: Optimized process significantly extends service life cycle.

- Spherical-specific protective cover: Custom silicone cover fits spherical structure to prevent scratches.

- Double protection for threaded ends: Screw cap + foam ring composite protection for precision threads.

- Live joint component positioning: Embedded foam bracket secures separate components.

- Anti-misassembly Marking: Left and right connectors distinguished by color codes + anti-reverse insertion design.

- Smart Size-Specific Packaging: Honeycomb cardboard compartments for size-specific organization and fixation.

- Visualized Operation Guide: Quick installation diagrams printed on the outer box.

- Full-Process Traceability System: Component laser coding + outer box QR code traceability.

- Anti-misoperation Locking Design: Transport locks prevent accidental separation of the quick-release connector.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.