HOT PRODUCTS TAGS

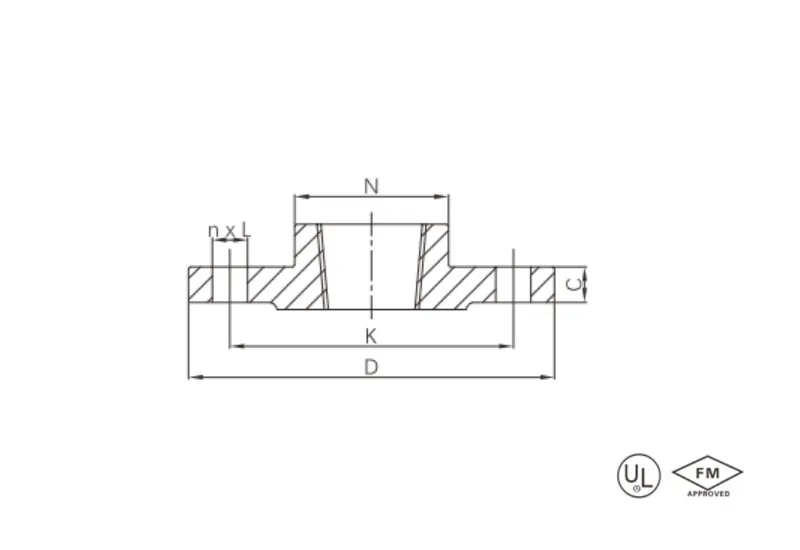

Malleable cast iron hubbed threaded flange

·Standard: ISO 49 / EN 10242

UL/FM

·Material: ISO 5922 JMB/350-10

·Thread: BSPT

·Flange facing: EN1092,FF/RF

·Pressure rating: PN16

·Surface: Black iron / hot dip galvanized

·Size Range: 1/2″ —2″

description

Malleable cast iron hubbed threaded flange, neck structure strengthens connection, threaded fastening, leak-proof and easy to install.

Specification

Available size

Size | Outside dia. | Neck dia. | Flange thk. | Bolt circle | Bolting | |

DN | OD (mm) | D (mm) | N (mm) | C (mm) | K (mm) | n x L |

32 | 42.4 | 140 | 60 | 18 | 100 | 4 x M16 |

40 | 48.3 | 150 | 70 | 18 | 110 | 4 x M16 |

50 | 60.3 | 165 | 84 | 20 | 125 | 4 x M16 |

65 | 76.1 | 185 | 104 | 20 | 145 | 8(4) x M16* |

80 | 88.9 | 200 | 120 | 20 | 160 | 8 x M16 |

100 | 114.3 | 220 | 140 | 22 | 180 | 8 x M16 |

Note:

The DN 65 malleable cast iron flange with PN16 can be supplied with 4 holes, so to match EN 1092-1

(Carbon steel flange) and EN 1092-3 (Copper alloy flange) connection

application

- Industrial pipeline terminal connections: Necked threaded flanges for deformation-resistant sealing connections between equipment and pipelines .

- Fire protection system expansion: UL-certified structures for high-pressure flange connections between sprinkler networks and pump valves .

- Ship propulsion systems: Anti-vibration flange solutions for engine room fuel/cooling water pipelines and equipment.

- Energy Transmission Networks: Sealed flange connections for oil and gas pipeline metering devices.

- Chemical Process Equipment: Corrosion-resistant flange interfaces for reactor inlet/outlet pipelines.

- Municipal Pipeline Network Renovation: Long-term sealed connections between main road valve assemblies and pipelines.

- Mining Equipment Integration: Anti-loosening flange solutions for pumps and pipelines in high-vibration conditions.

- Agricultural Irrigation Hubs: Flange connections between pump station high-pressure pipelines and filtration equipment.

advantages

- Reinforced structural design: Neck reinforcement ribs enhance the flange’s resistance to bending stress.

- Dual sealing protection: BSPT threads + flange sealing surface (FF/RF type) provide dual leak prevention.

- Easy installation: Threaded connections eliminate welding procedures, reducing installation complexity.

- Standard compatibility: Flange surfaces comply with EN1092 standards, compatible with PN16 carbon steel/copper alloy flanges.

- Long-Term Corrosion Protection System: Hot-dip galvanized coating certified by ISO 9227 salt spray test.

- Pressure Compatibility: PN16 rating meets industrial pipeline system pressure requirements.

- Optimized Bolt Hole Design: DN65 specification offers a 4-hole design option.

- Full Size Range Coverage: DN32-DN100 meets mainstream industrial pipeline requirements.

packing

- Sealing surface protection: the flange seal surface is covered with PE film.

- Protection of bolt holes: Engineering plastic plugs for the sealing of bolt holes in order to avoid yielding of damage.

- Heavy Transport SolutionMaterial: Steel-reinforced fumigated wooden box (complies with ISPM 15).

- Traceability management system: box QR code connected to material reports and standard certifications.

- Design with anti-deformation: Internal support frame that keeps the flange flat .

Available size

Size | Outside dia. | Neck dia. | Flange thk. | Bolt circle | Bolting | |

DN | OD (mm) | D (mm) | N (mm) | C (mm) | K (mm) | n x L |

32 | 42.4 | 140 | 60 | 18 | 100 | 4 x M16 |

40 | 48.3 | 150 | 70 | 18 | 110 | 4 x M16 |

50 | 60.3 | 165 | 84 | 20 | 125 | 4 x M16 |

65 | 76.1 | 185 | 104 | 20 | 145 | 8(4) x M16* |

80 | 88.9 | 200 | 120 | 20 | 160 | 8 x M16 |

100 | 114.3 | 220 | 140 | 22 | 180 | 8 x M16 |

Note:

The DN 65 malleable cast iron flange with PN16 can be supplied with 4 holes, so to match EN 1092-1

(Carbon steel flange) and EN 1092-3 (Copper alloy flange) connection

- Industrial pipeline terminal connections: Necked threaded flanges for deformation-resistant sealing connections between equipment and pipelines .

- Fire protection system expansion: UL-certified structures for high-pressure flange connections between sprinkler networks and pump valves .

- Ship propulsion systems: Anti-vibration flange solutions for engine room fuel/cooling water pipelines and equipment.

- Energy Transmission Networks: Sealed flange connections for oil and gas pipeline metering devices.

- Chemical Process Equipment: Corrosion-resistant flange interfaces for reactor inlet/outlet pipelines.

- Municipal Pipeline Network Renovation: Long-term sealed connections between main road valve assemblies and pipelines.

- Mining Equipment Integration: Anti-loosening flange solutions for pumps and pipelines in high-vibration conditions.

- Agricultural Irrigation Hubs: Flange connections between pump station high-pressure pipelines and filtration equipment.

- Reinforced structural design: Neck reinforcement ribs enhance the flange’s resistance to bending stress.

- Dual sealing protection: BSPT threads + flange sealing surface (FF/RF type) provide dual leak prevention.

- Easy installation: Threaded connections eliminate welding procedures, reducing installation complexity.

- Standard compatibility: Flange surfaces comply with EN1092 standards, compatible with PN16 carbon steel/copper alloy flanges.

- Long-Term Corrosion Protection System: Hot-dip galvanized coating certified by ISO 9227 salt spray test.

- Pressure Compatibility: PN16 rating meets industrial pipeline system pressure requirements.

- Optimized Bolt Hole Design: DN65 specification offers a 4-hole design option.

- Full Size Range Coverage: DN32-DN100 meets mainstream industrial pipeline requirements.

- Sealing surface protection: the flange seal surface is covered with PE film.

- Protection of bolt holes: Engineering plastic plugs for the sealing of bolt holes in order to avoid yielding of damage.

- Heavy Transport SolutionMaterial: Steel-reinforced fumigated wooden box (complies with ISPM 15).

- Traceability management system: box QR code connected to material reports and standard certifications.

- Design with anti-deformation: Internal support frame that keeps the flange flat .

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.