HOT PRODUCTS TAGS

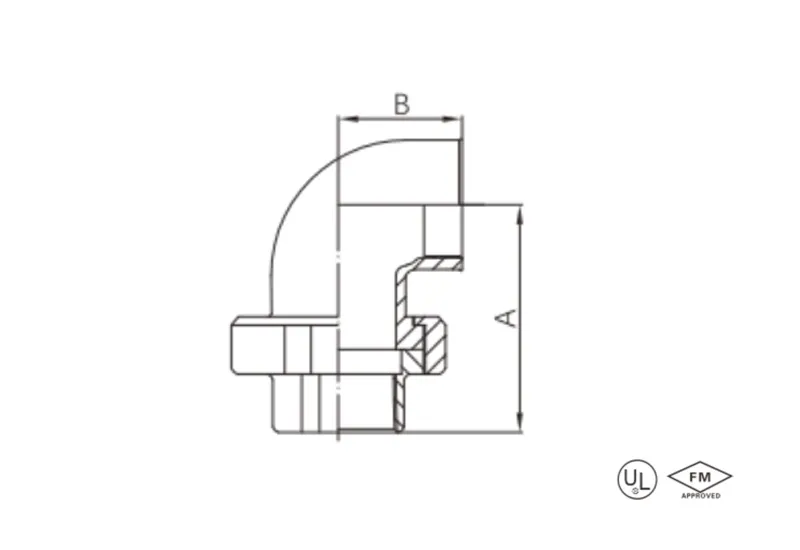

Malleable cast iron union elbow (Flat / taper seat)

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1/2″ —2″

description

Malleable cast iron union elbow (Flat /taper seat), flat/taper seat for leak-proof sealing, flexible steering, quickly connects various pipelines.

Specification

Available size

SIZE | A | B | Type | ||

INCH | DN | MM | MM | MM |

|

1/2″ | 15 | 21.3 | 57 | 27 | Flat seat / taper seat |

3/4″ | 20 | 26.9 | 59 | 29 | Flat seat / taper seat |

1″ | 25 | 33.7 | 72 | 34 | Flat seat / taper seat |

1-1/4″ | 32 | 42.4 | 82 | 43 | Flat seat / taper seat |

1-1/2″ | 40 | 48.3 | 88 | 47 | Flat seat / taper seat |

2″ | 50 | 60.3 | 99 | 56 | Flat seat / taper seat |

Note:

1.For flat seat, it must be fitted together with gasket for sealing, and TPMC could supply rubber gasket separately.

2.For taper (conical) seat, it is self-sealing without gasket.

3.For taper seat material of head and tail, it is malleable iron, and also available with both brass rings as customized.

4.NSF 61 certificate is available for M4003 ~ M4008.

application

- Equipment Space-Constrained Systems: Quick-connect elbow structures solve the challenges of pipe routing and maintenance within cabinets.

- Fire Protection Pipeline Renovation: UL-certified quick-connect elbows achieve high-pressure sealing and directional adjustment for sprinkler systems.

- Marine Power Piping: Compact space routing connection solutions for engine room fuel/cooling water piping.

- Industrial Equipment Integration: Removable Turning Connection Interfaces for Compressor/Heat Exchanger Piping.

- Energy Transmission Systems: Direction Adjustment and Rapid Maintenance Solutions for Oil and Gas Pipeline Inspection Ports.

- Agricultural Irrigation Hubs: Adjustable Directional Modular Connections for High-Pressure Piping in Pump Station Filtration Systems.

- Chemical Process Equipment: Frequent Disassembly and Maintenance of Piping Around Reactors.

- Mining Equipment Piping: Anti-Loosening Connections for Removable Elbows in High-Vibration Conditions.

advantages

- Functional Integration Design: The live joint architecture and the 90° elbow are integrated to reduce connections parts.

- Both flat seal (samplings with gasket) and conical seal (requires no gaskets for self-tightening feature) sealing configurations.

- Secure seal under high pressure: BSPT threaded configuration provides the utmost for sealing integrity in demanding industrial applications.

- Fast dismantling and assembly: Live connection design, easy disassembly of the pipeline without tools.

- Flexible direction adjustment: 90 degree turning angle to improve space layout efficiency.

- Material Configuration: Standard cast iron sealing surface / Optional Brass Seal Ring – Increased Corrosion Protection.

packing

- Sealing surface protection: PE protective film covers the sealing plane and conical surface of the elbow.

- Component packaging system: Live joints/sealing gaskets are individually packaged to prevent scratches.

- Anti-rust treatment: Vacuum composite packaging with vapor phase corrosion inhibitor (VCI) paper.

- Dedicated positioning structure: Laser-cut EVA lining is three-dimensionally positioned according to the shape of the elbow.

- Transportation Protection Solution: Steel-band reinforced fumigated wooden box (compliant with ISPM 15 standards).

- Traceability Management System: Box QR code linked to certification information and turning angle parameters.

- Collision Prevention Design: Buffer foam material added to the curved sections of elbows inside the box.

Available size

SIZE | A | B | Type | ||

INCH | DN | MM | MM | MM |

|

1/2″ | 15 | 21.3 | 57 | 27 | Flat seat / taper seat |

3/4″ | 20 | 26.9 | 59 | 29 | Flat seat / taper seat |

1″ | 25 | 33.7 | 72 | 34 | Flat seat / taper seat |

1-1/4″ | 32 | 42.4 | 82 | 43 | Flat seat / taper seat |

1-1/2″ | 40 | 48.3 | 88 | 47 | Flat seat / taper seat |

2″ | 50 | 60.3 | 99 | 56 | Flat seat / taper seat |

Note:

1.For flat seat, it must be fitted together with gasket for sealing, and TPMC could supply rubber gasket separately.

2.For taper (conical) seat, it is self-sealing without gasket.

3.For taper seat material of head and tail, it is malleable iron, and also available with both brass rings as customized.

4.NSF 61 certificate is available for M4003 ~ M4008.

- Equipment Space-Constrained Systems: Quick-connect elbow structures solve the challenges of pipe routing and maintenance within cabinets.

- Fire Protection Pipeline Renovation: UL-certified quick-connect elbows achieve high-pressure sealing and directional adjustment for sprinkler systems.

- Marine Power Piping: Compact space routing connection solutions for engine room fuel/cooling water piping.

- Industrial Equipment Integration: Removable Turning Connection Interfaces for Compressor/Heat Exchanger Piping.

- Energy Transmission Systems: Direction Adjustment and Rapid Maintenance Solutions for Oil and Gas Pipeline Inspection Ports.

- Agricultural Irrigation Hubs: Adjustable Directional Modular Connections for High-Pressure Piping in Pump Station Filtration Systems.

- Chemical Process Equipment: Frequent Disassembly and Maintenance of Piping Around Reactors.

- Mining Equipment Piping: Anti-Loosening Connections for Removable Elbows in High-Vibration Conditions.

- Functional Integration Design: The live joint architecture and the 90° elbow are integrated to reduce connections parts.

- Both flat seal (samplings with gasket) and conical seal (requires no gaskets for self-tightening feature) sealing configurations.

- Secure seal under high pressure: BSPT threaded configuration provides the utmost for sealing integrity in demanding industrial applications.

- Fast dismantling and assembly: Live connection design, easy disassembly of the pipeline without tools.

- Flexible direction adjustment: 90 degree turning angle to improve space layout efficiency.

- Material Configuration: Standard cast iron sealing surface / Optional Brass Seal Ring – Increased Corrosion Protection.

- Sealing surface protection: PE protective film covers the sealing plane and conical surface of the elbow.

- Component packaging system: Live joints/sealing gaskets are individually packaged to prevent scratches.

- Anti-rust treatment: Vacuum composite packaging with vapor phase corrosion inhibitor (VCI) paper.

- Dedicated positioning structure: Laser-cut EVA lining is three-dimensionally positioned according to the shape of the elbow.

- Transportation Protection Solution: Steel-band reinforced fumigated wooden box (compliant with ISPM 15 standards).

- Traceability Management System: Box QR code linked to certification information and turning angle parameters.

- Collision Prevention Design: Buffer foam material added to the curved sections of elbows inside the box.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.