HOT PRODUCTS TAGS

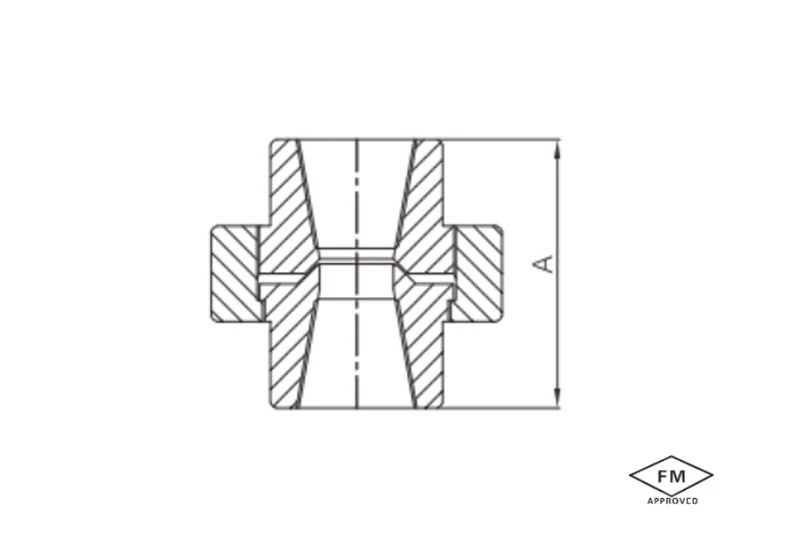

Malleable cast iron union (Flat / taper seat)

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1/4″ —6″

description

Malleable cast iron union (Flat /taper seat), flat/taper seat for leak-proof sealing, quick disassembly, fits various pipeline systems.

Specification

Available size

SIZE | A | Type | ||

INCH | DN | MM | MM |

|

1/4″ | 8 | 13.5 | 27 | Flat seat / taper seat |

3/8″ | 10 | 17.2 | 30 | Flat seat / taper seat |

1/2″ | 15 | 21.3 | 36 | Flat seat / taper seat |

3/4″ | 20 | 26.9 | 39 | Flat seat / taper seat |

1″ | 25 | 33.7 | 45 | Flat seat / taper seat |

1-1/4″ | 32 | 42.4 | 50 | Flat seat / taper seat |

1-1/2″ | 40 | 48.3 | 55 | Flat seat / taper seat |

2″ | 50 | 60.3 | 65 | Flat seat / taper seat |

2-1/2″ | 65 | 76.1 | 74 | Flat seat / taper seat |

3″ | 80 | 88.9 | 80 | Flat seat / taper seat |

4″ | 100 | 114.3 | 94 | Flat seat / taper seat |

6″ | 150 | 165.1 | 105 | Flat seat / taper seat |

Note:

1. For flat seat, it must be fitted together with gasket for sealing, and TPMC could supply rubber gasket separately.

2.For taper (conical) seat, it is self-sealing without gasket.

3.For taper seat material of head and tail, it is malleable iron, and also available with both brass rings as customized.

4.NSF 61 certificate is available for M3803 ~ M3811, except M3801, M3802, M3813

application

- Frequent maintenance of chemical systems: Flat/conical seal quick-connect couplings enable rapid disassembly and assembly of reaction vessel piping.

- Fire protection network maintenance: UL-certified quick-connect couplings ensure high-pressure sealing and efficient maintenance of sprinkler systems.

- Ship propulsion systems: Zero-leakage quick-connect solutions for fuel/cooling water piping in engine rooms under vibration conditions.

- Industrial equipment integration: Tool-free quick disassembly and connection for compressor/heat exchanger pipelines.

- Municipal valve assembly renovation: Sealing upgrades and maintenance optimization for main road flange systems.

- Energy transmission systems: Vibration-resistant quick-disconnect connections for oil and gas pipeline inspection ports.

- Agricultural irrigation hubs: Modular maintenance interfaces for high-pressure pipelines in pump station filtration systems.

- Mining pipeline networks: Quick replacement solutions for sealing surfaces in high-wear pipeline conditions.

advantages

- Dual-mode sealing design: flat seal (requires gasket)/conical seal (self-sealing) for on-demand adaptation .

- High-pressure sealing assurance: 25 bar operating conditions with BSPT thread structure to meet stringent sealing requirements .

- Quick installation and removal revolution: quick-connect structure enables tool-free disassembly and maintenance of pipeline systems .

- Long-lasting corrosion protection system: hot-dip galvanized coating certified by ISO 9227 salt spray test.

- Torsion-resistant structure reinforcement: Hexagonal flat design enhances installation torque transmission efficiency.

- Full specification coverage: DN8-DN150 meets requirements from instrumentation micro-pipes to main pipeline networks.

- Safety certification: Specific models comply with drinking water non-contamination standards.

- Flexible sealing options: Standard cast iron sealing surface / optional brass sealing ring customization.

packing

- Type of protection for sealing surfaces: PE protective film on flat/conical sealing areas.

- Packaged gaskets and hose fittings for separations to avoid abrasion.

- Rust prevention treatment: vacuum composite packaging with anticorrosive paper of VCI .

- Mistake-proofing geometry: Custom laser-cut EVA inner lining with component type-specific slots.

- Transportation boxes reinforced with steel bands (ISPM 15) for heavy equipment transport.

- Linking of Box QR code to certification information and seal type in a traceability management system.

- Loss-proof design:Self sealing bags + tamper evidence labels make sure component is intact .

Available size

SIZE | A | Type | ||

INCH | DN | MM | MM |

|

1/4″ | 8 | 13.5 | 27 | Flat seat / taper seat |

3/8″ | 10 | 17.2 | 30 | Flat seat / taper seat |

1/2″ | 15 | 21.3 | 36 | Flat seat / taper seat |

3/4″ | 20 | 26.9 | 39 | Flat seat / taper seat |

1″ | 25 | 33.7 | 45 | Flat seat / taper seat |

1-1/4″ | 32 | 42.4 | 50 | Flat seat / taper seat |

1-1/2″ | 40 | 48.3 | 55 | Flat seat / taper seat |

2″ | 50 | 60.3 | 65 | Flat seat / taper seat |

2-1/2″ | 65 | 76.1 | 74 | Flat seat / taper seat |

3″ | 80 | 88.9 | 80 | Flat seat / taper seat |

4″ | 100 | 114.3 | 94 | Flat seat / taper seat |

6″ | 150 | 165.1 | 105 | Flat seat / taper seat |

Note:

1. For flat seat, it must be fitted together with gasket for sealing, and TPMC could supply rubber gasket separately.

2.For taper (conical) seat, it is self-sealing without gasket.

3.For taper seat material of head and tail, it is malleable iron, and also available with both brass rings as customized.

4.NSF 61 certificate is available for M3803 ~ M3811, except M3801, M3802, M3813

- Frequent maintenance of chemical systems: Flat/conical seal quick-connect couplings enable rapid disassembly and assembly of reaction vessel piping.

- Fire protection network maintenance: UL-certified quick-connect couplings ensure high-pressure sealing and efficient maintenance of sprinkler systems.

- Ship propulsion systems: Zero-leakage quick-connect solutions for fuel/cooling water piping in engine rooms under vibration conditions.

- Industrial equipment integration: Tool-free quick disassembly and connection for compressor/heat exchanger pipelines.

- Municipal valve assembly renovation: Sealing upgrades and maintenance optimization for main road flange systems.

- Energy transmission systems: Vibration-resistant quick-disconnect connections for oil and gas pipeline inspection ports.

- Agricultural irrigation hubs: Modular maintenance interfaces for high-pressure pipelines in pump station filtration systems.

- Mining pipeline networks: Quick replacement solutions for sealing surfaces in high-wear pipeline conditions.

- Dual-mode sealing design: flat seal (requires gasket)/conical seal (self-sealing) for on-demand adaptation .

- High-pressure sealing assurance: 25 bar operating conditions with BSPT thread structure to meet stringent sealing requirements .

- Quick installation and removal revolution: quick-connect structure enables tool-free disassembly and maintenance of pipeline systems .

- Long-lasting corrosion protection system: hot-dip galvanized coating certified by ISO 9227 salt spray test.

- Torsion-resistant structure reinforcement: Hexagonal flat design enhances installation torque transmission efficiency.

- Full specification coverage: DN8-DN150 meets requirements from instrumentation micro-pipes to main pipeline networks.

- Safety certification: Specific models comply with drinking water non-contamination standards.

- Flexible sealing options: Standard cast iron sealing surface / optional brass sealing ring customization.

- Type of protection for sealing surfaces: PE protective film on flat/conical sealing areas.

- Packaged gaskets and hose fittings for separations to avoid abrasion.

- Rust prevention treatment: vacuum composite packaging with anticorrosive paper of VCI .

- Mistake-proofing geometry: Custom laser-cut EVA inner lining with component type-specific slots.

- Transportation boxes reinforced with steel bands (ISPM 15) for heavy equipment transport.

- Linking of Box QR code to certification information and seal type in a traceability management system.

- Loss-proof design:Self sealing bags + tamper evidence labels make sure component is intact .

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.