HOT PRODUCTS TAGS

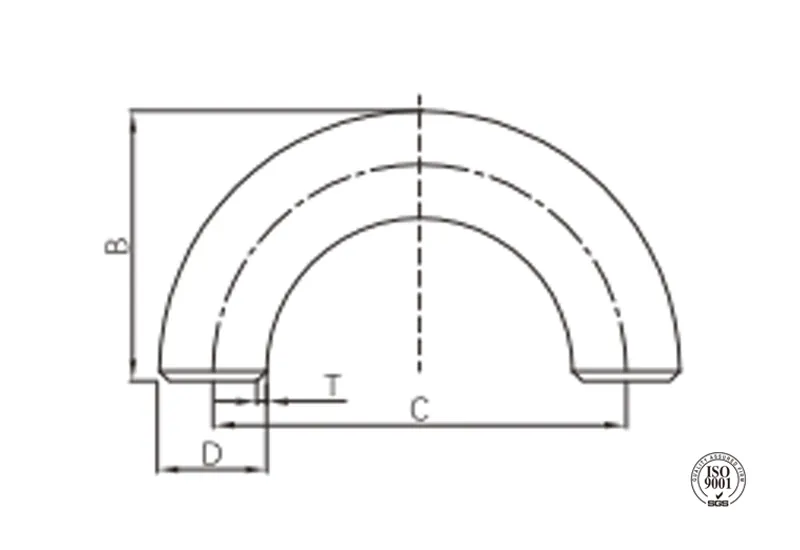

Butt weld 180° return bend (Long radius)

·Standard: ISO

EN 10253-1 / EN 10253-2 / EN 10253-3

·Material: Carbon steel S235 / P235TR2

SS equivalent to WP304 / WP316L

·Type: Long radius, 3D, R=1.5D

·W. pressure: Equal to same straight pipe

·Surface: Black painting / hot dip galvanized

Pickling white, etc.

·Size range: 1″-24″

description

butt weld 180 ° return bend (long radius), significantly reducing fluid resistance and energy loss, combined with butt welding connection to ensure high sealing and structural strength.

Specification

Available size

| Size | Preferred T to EN 10253-2(mm) | C(mm) | B(mm) | ||

| NPS | DN | OD(mm) | |||

| 1/2″ | 15 | 21.3 | 2.0/2.6/3.214.0/5.0/7.1 | 76 | 49 |

| 3/4″ | 20 | 26.9 | 2.3/2.6/3.214.0/4.5/5.6/8.0 | 76 | 51 |

| 1″ | 25 | 33.7 | 2.6/3.2/4.0/4.5/5.6/6.3/8.8 | 76 | 56 |

| 1-1/4″ | 32 | 42.4 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 95 | 69 |

| 1-1/2″ | 40 | 48.3 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 114 | 82 |

| 2″ | 50 | 60.3 | 2.9/3.614.0/5.6/7.1/8.8/11.0 | 152 | 106 |

| 2-1/2″ | 65 | 76.1 | 2.9/3.6/5.617.1/8.0/10.0/14.2 | 190 | 133 |

| 3″ | 80 | 88.9 | 3.2/4.0/5.6/8.0/8.8/11.0/16.0 | 228 | 159 |

| 4″ | 100 | 114.3 | 3.614.5/6.3/8.8/11.0/14.2/17.5 | 304 | 210 |

| 5″ | 125 | 139.7 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 380 | 260 |

| 6″ | 150 | 165.1/168.3 | 4.014.5/5.6/7.1/11.0/14.2/17.5/22.2 | 457 | 313 |

| 8″ | 200 | 219.1 | 4.5/6.3/7.1/8.0/12.5/16.0/17.5/22.2 | 610 | 414 |

| 10″ | 250 | 273.0 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 762 | 518 |

| 12″ | 300 | 323.9 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 914 | 619 |

| 14″ | 350 | 355.6 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 1066 | 711 |

| 16″ | 400 | 406.4 | 6.3/8.8/10.0/12.5/17.5122.2/30.0/40.0 | 1220 | 813 |

| 18″ | 450 | 457 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 1372 | 914 |

| 20″ | 500 | 508 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 1524 | 1016 |

| 24″ | 600 | 610 | 6.3/10.0/12.5/17.5125.0/30.0/45.0/60.0 | 1828 | 1219 |

application

- Used in pipeline systems for 180° complete reverse turns, enabling efficient fluid return flow or compact pipeline design.

- Suitable for applications requiring large angle turns and a reduction in the number of pipe fittings, such as heat exchanger connections, pump group circuits, chemical reaction equipment, and long-distance pipeline turning systems.

- Replaces multiple elbow combinations in scenarios where space is limited but low flow resistance must be ensured.

advantages

- Optimization of fluid dynamics: Furthermore, the long radius structure (R=1.5D) effectively decreases turbulence and pressure drop to save the system energy consumption.

- All-in-one high-strength design: No leakage butt-welded connections through out and enhance whole structure tight, eliminate weak points by multiple elbow joints.

- Material Corrosion resisistant Double-side T-joint: For carbon steel (S235/P235TR2) and stainless steel (e.g. wP304/WP316L) according to the operational requirements.

- Saving instalments of costs: Middle turning through 180° by a single component equals less number of welding point and simpler installation.

- Surface protection process: meet black paint spray, hot dip galvanizing or acid washing passivation treatment to enhance environmental resistance.

- Pressure compatibility: the pressure has the same capacity to bear as that of straight tubes of similar specification, with no increase in strength loss.

- Wide range applications: Full size coverage from 1 inch to 24 inches (NPS) and a large variety of sizes for ERW Straight Seam Steel Pipe, Spiral Welded Steel Pipe has wide market opportunities.

packing

- Heavy-duty protective packaging: Reinforced wooden boxes or multi-layer plywood boxes are used, with internal cushioning materials to prevent vibration and impact.

- Tube End Protection: Engineering plastic caps are installed at both ends to prevent deformation from impacts during transportation.

- Rust Prevention Treatment: The surface is wrapped in vapor-phase corrosion inhibitor (VCI) paper or coated with rust-preventive oil.

- Labeling Standards: The outer box is clearly labeled with product name, angle, material, dimensions, and orientation markers such as “↑Upward.”

Available size

| Size | Preferred T to EN 10253-2(mm) | C(mm) | B(mm) | ||

| NPS | DN | OD(mm) | |||

| 1/2″ | 15 | 21.3 | 2.0/2.6/3.214.0/5.0/7.1 | 76 | 49 |

| 3/4″ | 20 | 26.9 | 2.3/2.6/3.214.0/4.5/5.6/8.0 | 76 | 51 |

| 1″ | 25 | 33.7 | 2.6/3.2/4.0/4.5/5.6/6.3/8.8 | 76 | 56 |

| 1-1/4″ | 32 | 42.4 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 95 | 69 |

| 1-1/2″ | 40 | 48.3 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 114 | 82 |

| 2″ | 50 | 60.3 | 2.9/3.614.0/5.6/7.1/8.8/11.0 | 152 | 106 |

| 2-1/2″ | 65 | 76.1 | 2.9/3.6/5.617.1/8.0/10.0/14.2 | 190 | 133 |

| 3″ | 80 | 88.9 | 3.2/4.0/5.6/8.0/8.8/11.0/16.0 | 228 | 159 |

| 4″ | 100 | 114.3 | 3.614.5/6.3/8.8/11.0/14.2/17.5 | 304 | 210 |

| 5″ | 125 | 139.7 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 380 | 260 |

| 6″ | 150 | 165.1/168.3 | 4.014.5/5.6/7.1/11.0/14.2/17.5/22.2 | 457 | 313 |

| 8″ | 200 | 219.1 | 4.5/6.3/7.1/8.0/12.5/16.0/17.5/22.2 | 610 | 414 |

| 10″ | 250 | 273.0 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 762 | 518 |

| 12″ | 300 | 323.9 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 914 | 619 |

| 14″ | 350 | 355.6 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 1066 | 711 |

| 16″ | 400 | 406.4 | 6.3/8.8/10.0/12.5/17.5122.2/30.0/40.0 | 1220 | 813 |

| 18″ | 450 | 457 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 1372 | 914 |

| 20″ | 500 | 508 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 1524 | 1016 |

| 24″ | 600 | 610 | 6.3/10.0/12.5/17.5125.0/30.0/45.0/60.0 | 1828 | 1219 |

- Used in pipeline systems for 180° complete reverse turns, enabling efficient fluid return flow or compact pipeline design.

- Suitable for applications requiring large angle turns and a reduction in the number of pipe fittings, such as heat exchanger connections, pump group circuits, chemical reaction equipment, and long-distance pipeline turning systems.

- Replaces multiple elbow combinations in scenarios where space is limited but low flow resistance must be ensured.

- Optimization of fluid dynamics: Furthermore, the long radius structure (R=1.5D) effectively decreases turbulence and pressure drop to save the system energy consumption.

- All-in-one high-strength design: No leakage butt-welded connections through out and enhance whole structure tight, eliminate weak points by multiple elbow joints.

- Material Corrosion resisistant Double-side T-joint: For carbon steel (S235/P235TR2) and stainless steel (e.g. wP304/WP316L) according to the operational requirements.

- Saving instalments of costs: Middle turning through 180° by a single component equals less number of welding point and simpler installation.

- Surface protection process: meet black paint spray, hot dip galvanizing or acid washing passivation treatment to enhance environmental resistance.

- Pressure compatibility: the pressure has the same capacity to bear as that of straight tubes of similar specification, with no increase in strength loss.

- Wide range applications: Full size coverage from 1 inch to 24 inches (NPS) and a large variety of sizes for ERW Straight Seam Steel Pipe, Spiral Welded Steel Pipe has wide market opportunities.

- Heavy-duty protective packaging: Reinforced wooden boxes or multi-layer plywood boxes are used, with internal cushioning materials to prevent vibration and impact.

- Tube End Protection: Engineering plastic caps are installed at both ends to prevent deformation from impacts during transportation.

- Rust Prevention Treatment: The surface is wrapped in vapor-phase corrosion inhibitor (VCI) paper or coated with rust-preventive oil.

- Labeling Standards: The outer box is clearly labeled with product name, angle, material, dimensions, and orientation markers such as “↑Upward.”

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.