HOT PRODUCTS TAGS

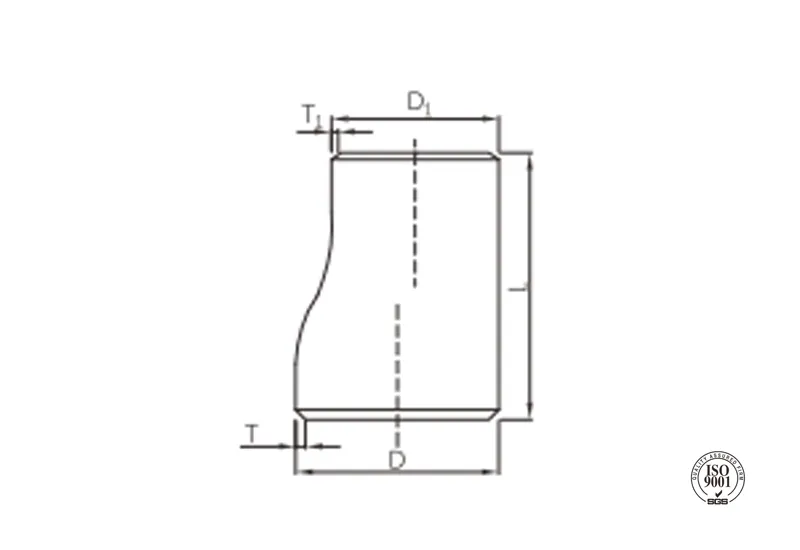

Butt weld eccentric reducer

·Standard: ISO

EN 10253-1 / EN 10253-2 / EN 10253-3

·Material: Carbon steel S235 / P235TR2

SS equivalent to WP304 / WP316L

·W. pressure: Equal to same straight pipe

·Surface: Black painting / hot dip galvanized

Pickling white, etc.

·Size range: 3/4″x1/2″—24″x10″

description

butt weld eccentric reducer is a conical pipe fitting that keeps the top or bottom of the pipe flush to avoid fluid retention. It is suitable for working conditions such as pump inlet and horizontal pipeline that require anti-cavitation or drainage.

Specification

Available size

| Size(DXD1) | Preferred T to EN 10253-2 (Large end,mm) | L(mm) | ||

| NPS | DN | OD(mm) | ||

| 3/4″x1/2″ | 20×15 | 26.9×21.3 | 2.3/2.6/3.214.0/4.5/5.6/8.0 | 38 |

| 1″x 3/4″ | 25×20 | 33.7×26.9 | 2.6/3.214.0/4.5/5.6/6.3/8.8 | 51 |

| 1″x 1/2″ | 25×15 | 33.7×21.3 | 2.6/3.2/4.0/4.5/5.6/6.3/8.8 | 51 |

| 1-1/4″x1″ | 32×25 | 42.4×33.7 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 51 |

| 1-1/4″x 3/4″ | 32×20 | 42.4×26.9 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 51 |

| 1-1/4″x 1/2″ | 32×15 | 42.4×21.3 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 51 |

| 1-1/2″x1-1/4″ | 40xx32 | 48.3×42.4 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 64 |

| 1-1/2″x1″ | 40×25 | 48.3×33.7 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 64 |

| 1-1/2″x 3/4″ | 40×20 | 48.3×26.9 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 64 |

| 1-1/2″x1/2″ | 40×15 | 48.3×21.3 | 2.6/3.614.0/5.0/6.3/8.0/10.0 | 64 |

| 2″x1-1/2″ | 50×40 | 60.3×48.3 | 2.9/3.6/4.0/5.6/7.1/8.8/11.0 | 76 |

| 2″x 1-1/4″ | 50×32 | 60.3×42.4 | 2.9/3.614.0/5.6/7.1/8.8/11.0 | 76 |

| 2″x1″ | 50×25 | 60.3×33.7 | 2.9/3.6/4.0/5.6/7.1/8.8/11.0 | 76 |

| 2″x 3/4″ | 50×20 | 60.3×26.9 | 2.9/3.614.0/5.6/7.1/8.8/11.0 | 76 |

| 2″x1/2″ | 50×15 | 60.3×21.3 | 2.9/3.6/4.0/5.617.1/8.8/11.0 | 76 |

| 2-1/2″x2″ | 65×50 | 76.1×60.3 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 89 |

| 2-1/2″x 1-1/2″ | 65×40 | 76.1×48.3 | 2.9/3.6/5.617.1/8.0/10.0/14.2 | 89 |

| 2-1/2″x 1-1/4″ | 65×32 | 76.1×42.4 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 89 |

| 2-1/2″x1″ | 65×25 | 76.1x 33.7 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 89 |

| 2-1/2″x3/4″ | 65×20 | 76.1×26.9 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 89 |

| 3″x2-1/2″ | 80×65 | 88.9×76.1 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 89 |

| 3″x2″ | 80×50 | 88.9×60.3 | 3.214.015.6/8.0/8.8/11.0/16.0 | 89 |

| 3″x1-1/2″ | 80×40 | 88.9×48.3 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 89 |

| 3″x1-1/4″ | 80×32 | 88.9×42.4 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 89 |

| 3″x1″ | 80×25 | 88.9×33.7 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 89 |

| 4″x3″ | 100×80 | 114.3×88.9 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 102 |

| 4″x2-1/2″ | 100×65 | 114.3×76.1 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 102 |

| 4″x2″ | 100×50 | 114.3×60.3 | 3.614.5/6.3/8.8/11.0/14.2/17.5 | 102 |

| 4″x1-1/2″ | 100×40 | 114.3×48.3 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 102 |

| 4″x1-1/4″ | 100×32 | 114.3×42.2 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 102 |

| 4″x1″ | 100×25 | 114.3×33.7 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 102 |

| 5″x4″ | 125×100 | 139.7×114.3 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 127 |

| 5″x3″ | 125×80 | 139.7×88.9 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 127 |

| 5″x2-1/2″ | 125×65 | 139.7×76.1 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 127 |

| 5″x2″ | 125×50 | 139.7×60.3 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 127 |

| 5″x1-1/2″ | 125×40 | 139.7×48.3 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 127 |

| 5″x1-1/4″ | 125×32 | 139.7×42.2 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 127 |

| 5″x1″ | 125×25 | 139.7×33.4 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 127 |

| 6″x5″ | 150×125 | 168.3×139.7 | 4.0/4.5/5.6/7.1/11.0/14.2/17.5122.2 | 140 |

| 6″x4″ | 150×100 | 168.3×114.3 | 4.0/4.5/5.6/7.1/11.0/14.21/17.5/22.2 | 140 |

| 6″x3″ | 150×80 | 168.3×88.9 | 4.0/4.5/5.6/7.1/11.0/14.21/17.5/22.2 | 140 |

| 6″x2-1/2″ | 150×65 | 168.3×76.1 | 4.0/4.5/5.6/7.1/11.0/14.2/17.5/22.2 | 140 |

| 6″x2″ | 150×50 | 168.3×60.3 | 4.014.5/5.6/7.1/11.0/14.2/17.5122.2 | 140 |

| 6″x1-1/2″ | 150×40 | 168.3×48.3 | 4.0/4.5/5.6/7.1/11.0/14.21/17.5/22.2 | 140 |

| 6″x1-1/4″ | 150×32 | 168.3×42.2 | 4.0/4.5/5.6/7.1/11.0/14.21/17.5/22.2 | 140 |

| 6″x1″ | 150×25 | 168.3×33.4 | 4.0/4.5/5.6/7.1/11.0/14.2/17.5/22.2 | 140 |

| 8″x6″ | 200×150 | 219.1×168.3 | 4.5/6.317.1/8.0/12.5/16.0/17.5/22.2 | 152 |

| 8″x5″ | 200×125 | 219.1×139.7 | 4.5/6.3/7.1/8.0/12.5/16.0/17.5/22.2 | 152 |

| 8″x4″ | 200×100 | 219.1×114.3 | 4.5/6.317.1/8.0/12.5/16.0/17.5/22.2 | 152 |

| 8″x3″ | 200×80 | 219.1×88.9 | 4.5/6.3/7.1/8.0/12.5/16.0/17.5/22.2 | 152 |

| 8″x2-1/2″ | 200×65 | 219.1×76.1 | 4.5/6.317.1/8.0/12.5/16.0/17.5/22.2 | 152 |

| 10″x8″ | 250×200 | 273.0×219.1 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 178 |

| 10″x6″ | 250×150 | 273.0×168.3 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 178 |

| 10″x5″ | 250×125 | 273.0×139.7 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 178 |

| 10″x4″ | 250×100 | 273.0×114.3 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2130.0 | 178 |

| 10″x3″ | 250×80 | 273.0×88.9 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 178 |

| 10″x2-1/2″ | 250×65 | 273.0×73.0 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 178 |

| 12″x10″ | 300×250 | 323.9×273.0 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 203 |

| 12″x8″ | 300×200 | 323.9×219.1 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 203 |

| 12″x6″ | 300×150 | 323.9×168.3 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 203 |

| 12″x5″ | 300×125 | 323.9×139.7 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 203 |

| 12″x4″ | 300×100 | 323.8×114.3 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 203 |

| 12″x3″ | 300×80 | 323.8×88.9 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 203 |

| 12″x2-1/2″ | 300×65 | 323.8×73.0 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 203 |

| 14″x12″ | 350×300 | 355.6×323.9 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 330 |

| 14″x10″ | 350×250 | 355.6×273.0 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 330 |

| 14″x8″ | 350×200 | 355.6×219.1 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 330 |

| 14″x6″ | 350×150 | 355.6×168.3 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 330 |

| 16″x 14″ | 400×350 | 406.4×355.6 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 356 |

| 16″x12″ | 400×300 | 406.4×323.9 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 356 |

| 16″x10″ | 400×250 | 406.4×273.0 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 356 |

| 16″x8″ | 400×200 | 406.4×219.1 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 356 |

| 16″x6″ | 400×150 | 406.4×168.3 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 356 |

| 18″x16″ | 450×400 | 457×406.4 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 381 |

| 18″x14″ | 450×350 | 457×355.6 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 381 |

| 18″x12″ | 450×300 | 457×323.9 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 381 |

| 18″x10″ | 450×250 | 457×273.0 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 381 |

| 18″x8″ | 450×200 | 457×219.1 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0145.0 | 381 |

| 20″x18″ | 500×450 | 508×457 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 508 |

| 20″x 16″ | 500×400 | 508×406.4 | 6.3/10.0/11.0/12.5117.5/25.0/36.0/50.0 | 508 |

| 20″x14″ | 500×350 | 508×355.6 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 508 |

| 20″x12″ | 500×300 | 508×323.9 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 508 |

| 20″x10″ | 500×250 | 508×273.0 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 508 |

| 20″x8″ | 500×200 | 508×219.1 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 508 |

| 24″x20″ | 600×500 | 610×508 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 508 |

| 24″x 18″ | 600×450 | 610×457 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 508 |

| 24″x 16″ | 600×400 | 610×406.4 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 508 |

| 24″x 14″ | 600×350 | 610×355.6 | 6.3/10.0/12.5/17.5/25.0/30.0145.0/60.0 | 508 |

| 24″x12″ | 600×300 | 610×323.9 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 508 |

| 24″x10″ | 600×250 | 610×273.0 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 508 |

Note:

- The thickness of above form refers to major OD, and thickness of minor OD is different.

- For size DN 150, it is also available with 165.1 mm as per EN 10255.

application

- Specially designed for horizontal piping systems, it achieves zero liquid accumulation/zero air pockets through a flush top or bottom structure, completely solving the problem of fluid residue.

- It is primarily used in applications such as pump inlet cavitation prevention, sewage pipeline blockage prevention, and steam pipeline drainage, where there are strict requirements for fluid drainage.

- It is indispensable in clean systems such as chemical, pharmaceutical, and food-grade pipelines where medium residue is not allowed.

advantages

- Intelligent Fluid Management:

- Top Flat Type: Prevents gas accumulation and ensures cavitation-free operation of the pump body.

- Bottom Flat Type: Eliminates liquid accumulation dead zones and achieves complete drainage of the pipeline.

- High-Pressure System Reinforcement: Integrated forged cone + fully welded joints, with pressure-bearing performance equivalent to straight pipe sections, eliminating the risk of flange leakage.

- Corrosion-Resistant Dual Shield System:

- Carbon Steel: Hot-dip galvanized (weather-resistant) or food-grade epoxy coating (compliant with FDA standards)

- Stainless steel: Electrolytic polishing (Ra ≤ 0.6 μm) meets GMP certification requirements

- Revolutionary installation breakthrough:Direct welding replaces flange assemblies + eccentric short sections, reducing welds by 70% and shortening construction time by 50%.

- Full-scenario compatibility:Covers the full range of specifications from 3/4“ × 1/2” to 24“ × 10”, compatible with various industrial systems from DN15 to DN600.

packing

- Position Locking Packaging:

- Use directional foam molds to fix the eccentric position (top/bottom flush mark facing up)

- Outer box covered with “↑Installation Direction↑” laser-etched warning

- Asymmetric Port Protection:

- Large diameter end: steel blind plate + rubber buffer ring

- Small-diameter end: Nylon screw-in cover + food-grade silicone seal

- Long-term rust prevention solution:

- Carbon steel components: VCI vapor phase rust prevention bags + rust-preventive oil coating

- Stainless steel components: Nitrogen-filled sealing + anti-fingerprint film

- Ultra-fast traceability system:Tube body laser marking with three codes integrated (model/offset type/material)

Available size

| Size(DXD1) | Preferred T to EN 10253-2 (Large end,mm) | L(mm) | ||

| NPS | DN | OD(mm) | ||

| 3/4″x1/2″ | 20×15 | 26.9×21.3 | 2.3/2.6/3.214.0/4.5/5.6/8.0 | 38 |

| 1″x 3/4″ | 25×20 | 33.7×26.9 | 2.6/3.214.0/4.5/5.6/6.3/8.8 | 51 |

| 1″x 1/2″ | 25×15 | 33.7×21.3 | 2.6/3.2/4.0/4.5/5.6/6.3/8.8 | 51 |

| 1-1/4″x1″ | 32×25 | 42.4×33.7 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 51 |

| 1-1/4″x 3/4″ | 32×20 | 42.4×26.9 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 51 |

| 1-1/4″x 1/2″ | 32×15 | 42.4×21.3 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 51 |

| 1-1/2″x1-1/4″ | 40xx32 | 48.3×42.4 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 64 |

| 1-1/2″x1″ | 40×25 | 48.3×33.7 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 64 |

| 1-1/2″x 3/4″ | 40×20 | 48.3×26.9 | 2.6/3.6/4.0/5.0/6.3/8.0/10.0 | 64 |

| 1-1/2″x1/2″ | 40×15 | 48.3×21.3 | 2.6/3.614.0/5.0/6.3/8.0/10.0 | 64 |

| 2″x1-1/2″ | 50×40 | 60.3×48.3 | 2.9/3.6/4.0/5.6/7.1/8.8/11.0 | 76 |

| 2″x 1-1/4″ | 50×32 | 60.3×42.4 | 2.9/3.614.0/5.6/7.1/8.8/11.0 | 76 |

| 2″x1″ | 50×25 | 60.3×33.7 | 2.9/3.6/4.0/5.6/7.1/8.8/11.0 | 76 |

| 2″x 3/4″ | 50×20 | 60.3×26.9 | 2.9/3.614.0/5.6/7.1/8.8/11.0 | 76 |

| 2″x1/2″ | 50×15 | 60.3×21.3 | 2.9/3.6/4.0/5.617.1/8.8/11.0 | 76 |

| 2-1/2″x2″ | 65×50 | 76.1×60.3 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 89 |

| 2-1/2″x 1-1/2″ | 65×40 | 76.1×48.3 | 2.9/3.6/5.617.1/8.0/10.0/14.2 | 89 |

| 2-1/2″x 1-1/4″ | 65×32 | 76.1×42.4 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 89 |

| 2-1/2″x1″ | 65×25 | 76.1x 33.7 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 89 |

| 2-1/2″x3/4″ | 65×20 | 76.1×26.9 | 2.9/3.6/5.6/7.1/8.0/10.0/14.2 | 89 |

| 3″x2-1/2″ | 80×65 | 88.9×76.1 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 89 |

| 3″x2″ | 80×50 | 88.9×60.3 | 3.214.015.6/8.0/8.8/11.0/16.0 | 89 |

| 3″x1-1/2″ | 80×40 | 88.9×48.3 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 89 |

| 3″x1-1/4″ | 80×32 | 88.9×42.4 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 89 |

| 3″x1″ | 80×25 | 88.9×33.7 | 3.214.0/5.6/8.0/8.8/11.0/16.0 | 89 |

| 4″x3″ | 100×80 | 114.3×88.9 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 102 |

| 4″x2-1/2″ | 100×65 | 114.3×76.1 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 102 |

| 4″x2″ | 100×50 | 114.3×60.3 | 3.614.5/6.3/8.8/11.0/14.2/17.5 | 102 |

| 4″x1-1/2″ | 100×40 | 114.3×48.3 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 102 |

| 4″x1-1/4″ | 100×32 | 114.3×42.2 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 102 |

| 4″x1″ | 100×25 | 114.3×33.7 | 3.6/4.5/6.3/8.8/11.0/14.2/17.5 | 102 |

| 5″x4″ | 125×100 | 139.7×114.3 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 127 |

| 5″x3″ | 125×80 | 139.7×88.9 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 127 |

| 5″x2-1/2″ | 125×65 | 139.7×76.1 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 127 |

| 5″x2″ | 125×50 | 139.7×60.3 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 127 |

| 5″x1-1/2″ | 125×40 | 139.7×48.3 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 127 |

| 5″x1-1/4″ | 125×32 | 139.7×42.2 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 127 |

| 5″x1″ | 125×25 | 139.7×33.4 | 4.0/5.0/6.3/10.0/12.5/16.0/20.0 | 127 |

| 6″x5″ | 150×125 | 168.3×139.7 | 4.0/4.5/5.6/7.1/11.0/14.2/17.5122.2 | 140 |

| 6″x4″ | 150×100 | 168.3×114.3 | 4.0/4.5/5.6/7.1/11.0/14.21/17.5/22.2 | 140 |

| 6″x3″ | 150×80 | 168.3×88.9 | 4.0/4.5/5.6/7.1/11.0/14.21/17.5/22.2 | 140 |

| 6″x2-1/2″ | 150×65 | 168.3×76.1 | 4.0/4.5/5.6/7.1/11.0/14.2/17.5/22.2 | 140 |

| 6″x2″ | 150×50 | 168.3×60.3 | 4.014.5/5.6/7.1/11.0/14.2/17.5122.2 | 140 |

| 6″x1-1/2″ | 150×40 | 168.3×48.3 | 4.0/4.5/5.6/7.1/11.0/14.21/17.5/22.2 | 140 |

| 6″x1-1/4″ | 150×32 | 168.3×42.2 | 4.0/4.5/5.6/7.1/11.0/14.21/17.5/22.2 | 140 |

| 6″x1″ | 150×25 | 168.3×33.4 | 4.0/4.5/5.6/7.1/11.0/14.2/17.5/22.2 | 140 |

| 8″x6″ | 200×150 | 219.1×168.3 | 4.5/6.317.1/8.0/12.5/16.0/17.5/22.2 | 152 |

| 8″x5″ | 200×125 | 219.1×139.7 | 4.5/6.3/7.1/8.0/12.5/16.0/17.5/22.2 | 152 |

| 8″x4″ | 200×100 | 219.1×114.3 | 4.5/6.317.1/8.0/12.5/16.0/17.5/22.2 | 152 |

| 8″x3″ | 200×80 | 219.1×88.9 | 4.5/6.3/7.1/8.0/12.5/16.0/17.5/22.2 | 152 |

| 8″x2-1/2″ | 200×65 | 219.1×76.1 | 4.5/6.317.1/8.0/12.5/16.0/17.5/22.2 | 152 |

| 10″x8″ | 250×200 | 273.0×219.1 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 178 |

| 10″x6″ | 250×150 | 273.0×168.3 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 178 |

| 10″x5″ | 250×125 | 273.0×139.7 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 178 |

| 10″x4″ | 250×100 | 273.0×114.3 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2130.0 | 178 |

| 10″x3″ | 250×80 | 273.0×88.9 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 178 |

| 10″x2-1/2″ | 250×65 | 273.0×73.0 | 5.0/6.3/8.8/10.0/12.5/16.0/22.2/30.0 | 178 |

| 12″x10″ | 300×250 | 323.9×273.0 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 203 |

| 12″x8″ | 300×200 | 323.9×219.1 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 203 |

| 12″x6″ | 300×150 | 323.9×168.3 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 203 |

| 12″x5″ | 300×125 | 323.9×139.7 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 203 |

| 12″x4″ | 300×100 | 323.8×114.3 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 203 |

| 12″x3″ | 300×80 | 323.8×88.9 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 203 |

| 12″x2-1/2″ | 300×65 | 323.8×73.0 | 5.6/7.1/8.8/10.0/12.5/17.5/25.0/32.0 | 203 |

| 14″x12″ | 350×300 | 355.6×323.9 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 330 |

| 14″x10″ | 350×250 | 355.6×273.0 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 330 |

| 14″x8″ | 350×200 | 355.6×219.1 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 330 |

| 14″x6″ | 350×150 | 355.6×168.3 | 5.6/8.0/10.0/12.5/16.0/20.0/28.0/36.0 | 330 |

| 16″x 14″ | 400×350 | 406.4×355.6 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 356 |

| 16″x12″ | 400×300 | 406.4×323.9 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 356 |

| 16″x10″ | 400×250 | 406.4×273.0 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 356 |

| 16″x8″ | 400×200 | 406.4×219.1 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 356 |

| 16″x6″ | 400×150 | 406.4×168.3 | 6.3/8.8/10.0/12.5/17.5/22.2/30.0/40.0 | 356 |

| 18″x16″ | 450×400 | 457×406.4 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 381 |

| 18″x14″ | 450×350 | 457×355.6 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 381 |

| 18″x12″ | 450×300 | 457×323.9 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 381 |

| 18″x10″ | 450×250 | 457×273.0 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0/45.0 | 381 |

| 18″x8″ | 450×200 | 457×219.1 | 6.3/10.0/11.0/12.5/17.5/22.2/32.0145.0 | 381 |

| 20″x18″ | 500×450 | 508×457 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 508 |

| 20″x 16″ | 500×400 | 508×406.4 | 6.3/10.0/11.0/12.5117.5/25.0/36.0/50.0 | 508 |

| 20″x14″ | 500×350 | 508×355.6 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 508 |

| 20″x12″ | 500×300 | 508×323.9 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 508 |

| 20″x10″ | 500×250 | 508×273.0 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 508 |

| 20″x8″ | 500×200 | 508×219.1 | 6.3/10.0/11.0/12.5/17.5/25.0/36.0/50.0 | 508 |

| 24″x20″ | 600×500 | 610×508 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 508 |

| 24″x 18″ | 600×450 | 610×457 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 508 |

| 24″x 16″ | 600×400 | 610×406.4 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 508 |

| 24″x 14″ | 600×350 | 610×355.6 | 6.3/10.0/12.5/17.5/25.0/30.0145.0/60.0 | 508 |

| 24″x12″ | 600×300 | 610×323.9 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 508 |

| 24″x10″ | 600×250 | 610×273.0 | 6.3/10.0/12.5/17.5/25.0/30.0/45.0/60.0 | 508 |

Note:

- The thickness of above form refers to major OD, and thickness of minor OD is different.

- For size DN 150, it is also available with 165.1 mm as per EN 10255.

- Specially designed for horizontal piping systems, it achieves zero liquid accumulation/zero air pockets through a flush top or bottom structure, completely solving the problem of fluid residue.

- It is primarily used in applications such as pump inlet cavitation prevention, sewage pipeline blockage prevention, and steam pipeline drainage, where there are strict requirements for fluid drainage.

- It is indispensable in clean systems such as chemical, pharmaceutical, and food-grade pipelines where medium residue is not allowed.

- Intelligent Fluid Management:

- Top Flat Type: Prevents gas accumulation and ensures cavitation-free operation of the pump body.

- Bottom Flat Type: Eliminates liquid accumulation dead zones and achieves complete drainage of the pipeline.

- High-Pressure System Reinforcement: Integrated forged cone + fully welded joints, with pressure-bearing performance equivalent to straight pipe sections, eliminating the risk of flange leakage.

- Corrosion-Resistant Dual Shield System:

- Carbon Steel: Hot-dip galvanized (weather-resistant) or food-grade epoxy coating (compliant with FDA standards)

- Stainless steel: Electrolytic polishing (Ra ≤ 0.6 μm) meets GMP certification requirements

- Revolutionary installation breakthrough:Direct welding replaces flange assemblies + eccentric short sections, reducing welds by 70% and shortening construction time by 50%.

- Full-scenario compatibility:Covers the full range of specifications from 3/4“ × 1/2” to 24“ × 10”, compatible with various industrial systems from DN15 to DN600.

- Position Locking Packaging:

- Use directional foam molds to fix the eccentric position (top/bottom flush mark facing up)

- Outer box covered with “↑Installation Direction↑” laser-etched warning

- Asymmetric Port Protection:

- Large diameter end: steel blind plate + rubber buffer ring

- Small-diameter end: Nylon screw-in cover + food-grade silicone seal

- Long-term rust prevention solution:

- Carbon steel components: VCI vapor phase rust prevention bags + rust-preventive oil coating

- Stainless steel components: Nitrogen-filled sealing + anti-fingerprint film

- Ultra-fast traceability system:Tube body laser marking with three codes integrated (model/offset type/material)

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.