HOT PRODUCTS TAGS

Butt weld reducing cross

·Standard: ISO

ASME B16.9

·Material: Carbon steel ASTM A234, WPB

SS ASTM A403, WP304 / WP316L

·W. pressure: Equal to same seamless pipe

·Surface: Black painting / hot dip galvanized Pickling white, etc.

·Size range: 3/4″x1/2″—24″x10″

description

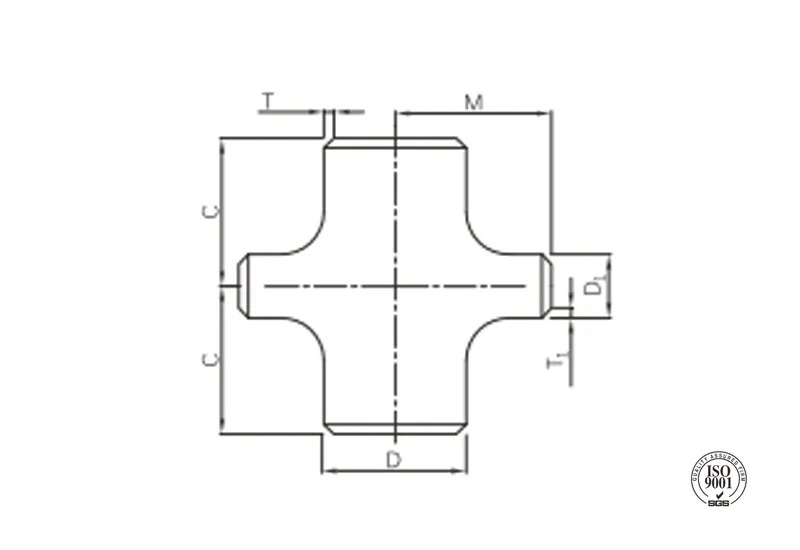

The shape of butt weld reducing is cross-shaped, and the size of the branch outlet is different from that of the main outlet. It is used to create two branch pipes in the direction of 90 degrees, with a high-strength pressure structure and precise flow control capabilities.

Specification

Available size

| Size(DXD₁) | Thickness TXT₁ (mm) | C(mm) | M(mm) | ||||

| NPS | DN | OD(mm) | Sch10 | Sch40 | Sch80 | ||

| 3/4″x1/2″ | 20×15 | 26.7×21.3 | 2.11×2.11 | 2.87×2.77 | 3.91×3.73 | 29 | 29 |

| 1″x3/4″ | 25×20 | 33.4×26.7 | 2.77×2.11 | 3.38×2.87 | 4.55x 3.91 | 38 | 38 |

| 1″x1/2″ | 25×15 | 33.4×21.3 | 2.77×2.11 | 3.38×2.77 | 4.55x 3.73 | 38 | 38 |

| 1-1/4″x1″ | 32×25 | 42.2×33.4 | 2.77×2.77 | 3.56x 3.38 | 4.85×4.55 | 48 | 48 |

| 1-1/4″x3/4″ | 32x 20 | 42.2×26.7 | 2.77×2.11 | 3.56×2.87 | 4.85×3.91 | 48 | 48 |

| 1-1/4″x1/2″ | 32×15 | 42.2×21.3 | 2.77×2.11 | 3.56×2.77 | 4.85×3.73 | 48 | 48 |

| -1/2″x1-1/4″ | 40×32 | 48.3×42.2 | 2.77×2.77 | 3.68x 3.56 | 5.08×4.85 | 57 | 57 |

| 1-1/2″x1″ | 40×25 | 48.3×33.4 | 2.77×2.77 | 3.68×3.38 | 5.08×4.55 | 57 | 57 |

| 1-1/2″x3/4″ | 40×20 | 48.3×26.7 | 2.77×2.11 | 3.68×2.87 | 5.08×3.91 | 57 | 57 |

| 1-1/2″x1/2″ | 40×15 | 48.3×21.3 | 2.77×2.11 | 3.68×2.77 | 5.08×3.73 | 57 | 57 |

| 2″x 1-1/2″ | 50×40 | 60.3×48.3 | 2.77×2.77 | 3.91x 3.68 | 5.54×5.08 | 64 | 60 |

| 2″x 1-1/4″ | 50×32 | 60.3×42.2 | 2.77×2.77 | 3.91×3.56 | 5.54×4.85 | 64 | 57 |

| 2″x1″ | 50×25 | 60.3×33.4 | 2.77×2.77 | 3.91x 3.38 | 5.54×4.55 | 64 | 51 |

| 2″x 3/4″ | 50×20 | 60.3×26.7 | 2.77×2.11 | 3.91×2.87 | 5.54×3.91 | 64 | 44 |

| 2″x 1/2″ | 50×15 | 60.3×21.3 | 2.77×2.11 | 3.91×2.77 | 5.54×3.73 | 64 | 38 |

| 2-1/2″x2″ | 65×50 | 73.0×60.3 | 3.05×2.77 | 5.16×3.91 | 7.01×5.54 | 76 | 70 |

| 2-1/2″x1-1/2″ | 65×40 | 73.0×48.3 | 3.05×2.77 | 5.16×3.68 | 7.01×5.08 | 76 | 67 |

| 2-1/2″x1-1/4″ | 65×32 | 73.0×42.2 | 3.05×2.77 | 5.16x 3.56 | 7.01×4.85 | 76 | 64 |

| 2-1/2″x1″ | 65×25 | 73.0×33.4 | 3.05×2.77 | 5.16×3.38 | 7.01×4.55 | 76 | 57 |

| 2-1/2″x3/4″ | 65×20 | 73.0×26.7 | 3.05×2.11 | 5.16×2.87 | 7.01×3.91 | 76 | 51 |

| 3″x2-1/2″ | 80×65 | 88.9×73.0 | 3.05×3.05 | 5.49×5.16 | 7.62×7.01 | 86 | 83 |

| 3″x2″ | 80×50 | 88.9×60.3 | 3.05×2.77 | 5.49×3.91 | 7.62×5.54 | 86 | 76 |

| 3″x 1-1/2″ | 80×40 | 88.9×48.3 | 3.05×2.77 | 5.49×3.68 | 7.62×5.08 | 86 | 73 |

| 3″x 1-1/4″ | 80×32 | 88.9×42.2 | 3.05×2.77 | 5.49×3.56 | 7.62×4.85 | 86 | 70 |

| 3″x1″ | 80×25 | 88.9×33.4 | 3.05×2.77 | 5.49×3.38 | 7.62×4.55 | 86 | 57 |

| 4″x3″ | 100×80 | 114.3×88.9 | 3.05×3.05 | 6.02×5.49 | 8.56×7.62 | 105 | 98 |

| 4″x2-1/2″ | 100×65 | 114.3×73.0 | 3.05×3.05 | 6.02×5.16 | 8.56×7.01 | 105 | 95 |

| 4″x2″ | 100×50 | 114.3×60.3 | 3.05×2.77 | 6.02×3.91 | 8.56×5.54 | 105 | 89 |

| 4″x1-1/2″ | 100×40 | 114.3×48.3 | 3.05×2.77 | 6.02×3.68 | 8.56×5.08 | 105 | 86 |

| 4″x1-1/4″ | 100×32 | 114.3×42.2 | 3.05×2.77 | 6.02×3.56 | 8.56×4.85 | 105 | 70 |

| 4″x1″ | 100×25 | 114.3×33.4 | 3.05×2.77 | 6.02x 3.38 | 8.56×4.55 | 105 | 57 |

| 5″x4″ | 125×100 | 141.3×114.3 | 3.40×3.05 | 6.55×6.02 | 9.53×8.56 | 124 | 117 |

| 5″x3″ | 125×80 | 141.3×88.9 | 3.40×3.05 | 6.55×5.49 | 9.53×7.62 | 124 | 111 |

| 5″x2-1/2″ | 125×65 | 141.3×73.0 | 3.40×3.05 | 6.55×5.16 | 9.53×7.01 | 124 | 108 |

| 5″x2″ | 125×50 | 141.3×60.3 | 3.40×2.77 | 6.55×3.91 | 9.53×5.54 | 124 | 105 |

| 5″x 1-1/2″ | 125×40 | 141.3×48.3 | 3.40×2.77 | 6.55×3.68 | 9.53×5.08 | 124 | 97 |

| 5″x1-1/4″ | 125×32 | 141.3×42.2 | 3.40×2.77 | 6.55×3.56 | 9.53×4.85 | 124 | 70 |

| 5″x1″ | 125×25 | 141.3×33.4 | 3.40×2.77 | 6.55×3.38 | 9.53×4.55 | 124 | 57 |

| 6″x5″ | 150×125 | 168.3×141.3 | 3.40×3.40 | 7.11×6.55 | 10.97×9.53 | 143 | 137 |

| 6″x4″ | 150×100 | 168.3×114.3 | 3.40×3.05 | 7.11×6.02 | 10.97×8.56 | 143 | 130 |

| 6″x3″ | 150×80 | 168.3×88.9 | 3.40×3.05 | 7.11×5.49 | 10.97×7.62 | 143 | 124 |

| 6″x2-1/2″ | 150×65 | 168.3×73.0 | 3.40×3.05 | 7.11×5.16 | 10.97×7.01 | 143 | 121 |

| 6″x2″ | 150×50 | 168.3×60.3 | 3.40×2.77 | 7.11×3.91 | 10.97×5.54 | 143 | 105 |

| 6″x 1-1/2″ | 150×40 | 168.3×48.3 | 3.40×2.77 | 7.11×3.68 | 10.97×5.08 | 143 | 97 |

| 6″x 1-1/4″ | 150×32 | 168.3×42.2 | 3.40×2.77 | 7.11×3.56 | 10.97×4.85 | 143 | 70 |

| 6″x1″ | 150×25 | 168.3×33.4 | 3.40×2.77 | 7.11×3.38 | 10.97×4.55 | 143 | 57 |

| 8″x6″ | 200×150 | 219.1×168.3 | 3.76×3.40 | 8.18×7.11 | 12.70×10.97 | 178 | 168 |

| 8″x5″ | 200×125 | 219.1×141.3 | 3.76×3.40 | 8.18×6.55 | 12.70×9.53 | 178 | 162 |

| 8″x4″ | 200×100 | 219.1×114.3 | 3.76×3.05 | 8.18×6.02 | 12.70×8.56 | 178 | 156 |

| 8″x3″ | 200×80 | 219.1×88.9 | 219.3×88.9 | 3.76×3.05 | 12.70×7.62 | 178 | 124 |

| 8″x2-1/2″ | 200×65 | 219.1×73.0 | 219.1×73.0 | 3.76×3.05 | 12.70×7.01 | 178 | 121 |

| 10″x8″ | 250×200 | 273.0×219.1 | 4.19×3.76 | 9.27×8.18 | 15.09×12.70 | 216 | 203 |

| 10″x6″ | 250×150 | 273.0×168.3 | 4.19×3.40 | 9.27×7.11 | 15.09×10.97 | 216 | 194 |

| 10″x5″ | 250×125 | 273.0×141.3 | 4.19×3.40 | 9.27×6.55 | 15.09×9.53 | 216 | 191 |

| 10″x4″ | 250×100 | 273.0×114.3 | 4.19×3.05 | 9.27×6.02 | 15.09×8.56 | 216 | 184 |

| 12″x10″ | 300×250 | 323.8×273.0 | 4.57×4.19 | 10.31×9.27 | 17.48×15.09 | 254 | 241 |

| 12″x8″ | 300×200 | 323.8×219.1 | 4.57×3.76 | 10.31×8.18 | 17.48×12.70 | 254 | 229 |

| 12″x6″ | 300×150 | 323.8×168.3 | 4.57×3.40 | 10.31×7.11 | 17.48×10.97 | 254 | 219 |

| 12″x5″ | 300×125 | 323.8×141.3 | 4.57×3.40 | 10.31×6.55 | 17.48×9.53a | 254 | 216 |

| 14″x12″ | 350×300 | 355.6×323.8 | 6.35×4.57 | 11.13×10.31 | 19.05×17.48 | 279 | 270 |

| 14″x10″ | 350×250 | 355.6×273.0 | 6.35×4.19 | 11.13×9.27 | 19.05×15.09 | 279 | 257 |

| 14″x8″ | 350×200 | 355.6×219.1 | 6.35×3.76 | 11.13×8.18 | 19.05×12.70 | 279 | 248 |

| 14″x6″ | 350×150 | 355.6×168.3 | 6.35×3.40 | 11.13×7.11 | 19.05×10.97 | 279 | 238 |

| 16″x14″ | 400×350 | 406.4×355.6 | 6.35×6.35 | 12.70×11.13 | 21.44×19.05 | 305 | 305 |

| 16″x12″ | 400×300 | 406.4×323.8 | 6.35×4.57 | 12.70×10.31 | 21.44×17.48 | 305 | 295 |

| 16″x10″ | 400×250 | 406.4×273.0 | 6.35×4.19 | 12.70×9.27 | 21.44×15.09 | 305 | 283 |

| 16″x8″ | 400×200 | 406.4×219.1 | 6.35×3.76 | 12.70×8.18 | 21.44×12.70 | 305 | 273 |

| 16″x6″ | 400×150 | 406.4×168.3 | 6.35×3.40 | 12.70×7.11 | 21.44×10.97 | 305 | 264 |

| 18″x16″ | 450×400 | 457×406.4 | 6.35×6.35 | 14.27×12.70 | 23.83×21.44 | 343 | 330 |

| 18″x14″ | 450×350 | 457×355.6 | 6.35×6.35 | 14.27×11.13 | 23.83×19.05 | 343 | 330 |

| 18″x12″ | 450×300 | 457×323.8 | 6.35×4.57 | 14.27×10.31 | 23.83×17.48 | 343 | 321 |

| 18″x10″ | 450×250 | 457×273.0 | 6.35×4.19 | 14.27×9.27 | 23.83×15.09 | 343 | 308 |

| 18″x8″ | 450×200 | 457×219.1 | 6.35×3.76 | 14.27×8.18 | 23.83×12.70 | 343 | 298 |

| 20″x18″ | 500×450 | 508×457 | 6.35×6.35 | 15.09×14.27 | 26.19×23.83 | 381 | 368 |

| 20″x16″ | 500×400 | 508×406.4 | 6.35×6.35 | 15.09×12.70 | 26.19×21.44 | 381 | 356 |

| 20″x14″ | 500×350 | 508×355.6 | 6.35×6.35 | 15.09×11.13 | 26.19×19.05 | 381 | 356 |

| 20″x12″ | 500×300 | 508×323.8 | 6.35×4.57 | 15.09×10.31 | 26.19×17.48 | 381 | 346 |

| 20″x10″ | 500×250 | 508×273.0 | 6.35×4.19 | 15.09×9.27 | 26.19×15.09 | 381 | 333 |

| 20″x8″ | 500×200 | 508×219.1 | 6.35×3.76 | 15.09×8.18 | 26.19×12.70 | 381 | 324 |

| 24″x20″ | 600×500 | 610×508 | 6.35×6.35 | 17.48×15.09 | 30.96×26.19 | 432 | 432 |

| 24″x18″ | 600×450 | 610×457 | 6.35×6.35 | 17.48×14.27 | 30.96×23.83 | 432 | 419 |

| 24″x16″ | 600×400 | 610×406.4 | 6.35×6.35 | 17.48×12.70 | 30.96×21.44 | 432 | 406 |

| 24″x14″ | 600×350 | 610×355.6 | 6.35×6.35 | 17.48×11.13 | 30.96×19.05 | 432 | 406 |

| 24″x12″ | 600×300 | 610×323.8 | 6.35×4.57 | 17.48×10.31 | 30.96×17.48 | 432 | 397 |

| 24″x10″ | 600×250 | 610×273.0 | 6.35×4.19 | 17.48×9.27 | 30.96×15.09 | 432 | 384 |

Note: The thickness is available with Sch5, Sch10, Sch30, Sch40, Sch80, Sch120, Sch160, STD, XS, XXS, 5S, 10S, 40S, 80S, etc.

application

- Complex diversion system: Used in industrial scenarios where the main pipeline needs to divert into two branch pipes of different diameters at the same time (such as multi-output chemical reactors and energy station cooling systems).

- Pressure grading control: Suitable for pipe networks that require differentiated regulation of branch flow and pressure (such as main production lines distributed to equipment of different specifications).

- Key industries: Petrochemical, power transmission, ship piping, and other high-pressure/high-sealing requirement fields.

advantages

- Diameter Division Precision: Free combination of the main pipe and the branch pipe specifications (e.g., 24”×10”) to realize the exact flow distribution.

- Structural reliability:Has a pressure capacity equivalent to that of seamless pipes of the same specification, so it is very strong nd can bear high pressure and vibration.

- Seal tightness: The welding joint is permanently free of leakage, which is suitable for sealing over corrosive and high temperature media.

- Carbon steel (ASTM A234 WPB)basic grade with a wide range of material variety and very suited to standard working conditions.

- Stainless Steel (304/316L): Resistance to corrosion, appropriate for high hygiene requirements of food, pharmaceutical, and other industries.

- Global Compatible: Meets ISO and ASME B16 global standards. 9, to ensure the interchangeability and installation time of the system .

packing

- Surface Protection Customization:

- Normal Environment: Black paint coating for rust prevention.

- Highly Corrosive Environment: Hot-dip galvanizing or acid washing and passivation treatment.

- Graded Packaging Solution:

- Small Size (≤6″): Bundled with steel straps, with corner protection for collision prevention.

- Large Size (>6″): Customized wooden boxes for individual protection, filled with shock-absorbing materials inside.

- Smart Identification:

- Outer boxes marked with main/branch pipe diameters (e.g., DN200xDN100), material codes, and flow direction arrows.

- Moisture-proof warning labels affixed to indicate storage conditions.

Available size

| Size(DXD₁) | Thickness TXT₁ (mm) | C(mm) | M(mm) | ||||

| NPS | DN | OD(mm) | Sch10 | Sch40 | Sch80 | ||

| 3/4″x1/2″ | 20×15 | 26.7×21.3 | 2.11×2.11 | 2.87×2.77 | 3.91×3.73 | 29 | 29 |

| 1″x3/4″ | 25×20 | 33.4×26.7 | 2.77×2.11 | 3.38×2.87 | 4.55x 3.91 | 38 | 38 |

| 1″x1/2″ | 25×15 | 33.4×21.3 | 2.77×2.11 | 3.38×2.77 | 4.55x 3.73 | 38 | 38 |

| 1-1/4″x1″ | 32×25 | 42.2×33.4 | 2.77×2.77 | 3.56x 3.38 | 4.85×4.55 | 48 | 48 |

| 1-1/4″x3/4″ | 32x 20 | 42.2×26.7 | 2.77×2.11 | 3.56×2.87 | 4.85×3.91 | 48 | 48 |

| 1-1/4″x1/2″ | 32×15 | 42.2×21.3 | 2.77×2.11 | 3.56×2.77 | 4.85×3.73 | 48 | 48 |

| -1/2″x1-1/4″ | 40×32 | 48.3×42.2 | 2.77×2.77 | 3.68x 3.56 | 5.08×4.85 | 57 | 57 |

| 1-1/2″x1″ | 40×25 | 48.3×33.4 | 2.77×2.77 | 3.68×3.38 | 5.08×4.55 | 57 | 57 |

| 1-1/2″x3/4″ | 40×20 | 48.3×26.7 | 2.77×2.11 | 3.68×2.87 | 5.08×3.91 | 57 | 57 |

| 1-1/2″x1/2″ | 40×15 | 48.3×21.3 | 2.77×2.11 | 3.68×2.77 | 5.08×3.73 | 57 | 57 |

| 2″x 1-1/2″ | 50×40 | 60.3×48.3 | 2.77×2.77 | 3.91x 3.68 | 5.54×5.08 | 64 | 60 |

| 2″x 1-1/4″ | 50×32 | 60.3×42.2 | 2.77×2.77 | 3.91×3.56 | 5.54×4.85 | 64 | 57 |

| 2″x1″ | 50×25 | 60.3×33.4 | 2.77×2.77 | 3.91x 3.38 | 5.54×4.55 | 64 | 51 |

| 2″x 3/4″ | 50×20 | 60.3×26.7 | 2.77×2.11 | 3.91×2.87 | 5.54×3.91 | 64 | 44 |

| 2″x 1/2″ | 50×15 | 60.3×21.3 | 2.77×2.11 | 3.91×2.77 | 5.54×3.73 | 64 | 38 |

| 2-1/2″x2″ | 65×50 | 73.0×60.3 | 3.05×2.77 | 5.16×3.91 | 7.01×5.54 | 76 | 70 |

| 2-1/2″x1-1/2″ | 65×40 | 73.0×48.3 | 3.05×2.77 | 5.16×3.68 | 7.01×5.08 | 76 | 67 |

| 2-1/2″x1-1/4″ | 65×32 | 73.0×42.2 | 3.05×2.77 | 5.16x 3.56 | 7.01×4.85 | 76 | 64 |

| 2-1/2″x1″ | 65×25 | 73.0×33.4 | 3.05×2.77 | 5.16×3.38 | 7.01×4.55 | 76 | 57 |

| 2-1/2″x3/4″ | 65×20 | 73.0×26.7 | 3.05×2.11 | 5.16×2.87 | 7.01×3.91 | 76 | 51 |

| 3″x2-1/2″ | 80×65 | 88.9×73.0 | 3.05×3.05 | 5.49×5.16 | 7.62×7.01 | 86 | 83 |

| 3″x2″ | 80×50 | 88.9×60.3 | 3.05×2.77 | 5.49×3.91 | 7.62×5.54 | 86 | 76 |

| 3″x 1-1/2″ | 80×40 | 88.9×48.3 | 3.05×2.77 | 5.49×3.68 | 7.62×5.08 | 86 | 73 |

| 3″x 1-1/4″ | 80×32 | 88.9×42.2 | 3.05×2.77 | 5.49×3.56 | 7.62×4.85 | 86 | 70 |

| 3″x1″ | 80×25 | 88.9×33.4 | 3.05×2.77 | 5.49×3.38 | 7.62×4.55 | 86 | 57 |

| 4″x3″ | 100×80 | 114.3×88.9 | 3.05×3.05 | 6.02×5.49 | 8.56×7.62 | 105 | 98 |

| 4″x2-1/2″ | 100×65 | 114.3×73.0 | 3.05×3.05 | 6.02×5.16 | 8.56×7.01 | 105 | 95 |

| 4″x2″ | 100×50 | 114.3×60.3 | 3.05×2.77 | 6.02×3.91 | 8.56×5.54 | 105 | 89 |

| 4″x1-1/2″ | 100×40 | 114.3×48.3 | 3.05×2.77 | 6.02×3.68 | 8.56×5.08 | 105 | 86 |

| 4″x1-1/4″ | 100×32 | 114.3×42.2 | 3.05×2.77 | 6.02×3.56 | 8.56×4.85 | 105 | 70 |

| 4″x1″ | 100×25 | 114.3×33.4 | 3.05×2.77 | 6.02x 3.38 | 8.56×4.55 | 105 | 57 |

| 5″x4″ | 125×100 | 141.3×114.3 | 3.40×3.05 | 6.55×6.02 | 9.53×8.56 | 124 | 117 |

| 5″x3″ | 125×80 | 141.3×88.9 | 3.40×3.05 | 6.55×5.49 | 9.53×7.62 | 124 | 111 |

| 5″x2-1/2″ | 125×65 | 141.3×73.0 | 3.40×3.05 | 6.55×5.16 | 9.53×7.01 | 124 | 108 |

| 5″x2″ | 125×50 | 141.3×60.3 | 3.40×2.77 | 6.55×3.91 | 9.53×5.54 | 124 | 105 |

| 5″x 1-1/2″ | 125×40 | 141.3×48.3 | 3.40×2.77 | 6.55×3.68 | 9.53×5.08 | 124 | 97 |

| 5″x1-1/4″ | 125×32 | 141.3×42.2 | 3.40×2.77 | 6.55×3.56 | 9.53×4.85 | 124 | 70 |

| 5″x1″ | 125×25 | 141.3×33.4 | 3.40×2.77 | 6.55×3.38 | 9.53×4.55 | 124 | 57 |

| 6″x5″ | 150×125 | 168.3×141.3 | 3.40×3.40 | 7.11×6.55 | 10.97×9.53 | 143 | 137 |

| 6″x4″ | 150×100 | 168.3×114.3 | 3.40×3.05 | 7.11×6.02 | 10.97×8.56 | 143 | 130 |

| 6″x3″ | 150×80 | 168.3×88.9 | 3.40×3.05 | 7.11×5.49 | 10.97×7.62 | 143 | 124 |

| 6″x2-1/2″ | 150×65 | 168.3×73.0 | 3.40×3.05 | 7.11×5.16 | 10.97×7.01 | 143 | 121 |

| 6″x2″ | 150×50 | 168.3×60.3 | 3.40×2.77 | 7.11×3.91 | 10.97×5.54 | 143 | 105 |

| 6″x 1-1/2″ | 150×40 | 168.3×48.3 | 3.40×2.77 | 7.11×3.68 | 10.97×5.08 | 143 | 97 |

| 6″x 1-1/4″ | 150×32 | 168.3×42.2 | 3.40×2.77 | 7.11×3.56 | 10.97×4.85 | 143 | 70 |

| 6″x1″ | 150×25 | 168.3×33.4 | 3.40×2.77 | 7.11×3.38 | 10.97×4.55 | 143 | 57 |

| 8″x6″ | 200×150 | 219.1×168.3 | 3.76×3.40 | 8.18×7.11 | 12.70×10.97 | 178 | 168 |

| 8″x5″ | 200×125 | 219.1×141.3 | 3.76×3.40 | 8.18×6.55 | 12.70×9.53 | 178 | 162 |

| 8″x4″ | 200×100 | 219.1×114.3 | 3.76×3.05 | 8.18×6.02 | 12.70×8.56 | 178 | 156 |

| 8″x3″ | 200×80 | 219.1×88.9 | 219.3×88.9 | 3.76×3.05 | 12.70×7.62 | 178 | 124 |

| 8″x2-1/2″ | 200×65 | 219.1×73.0 | 219.1×73.0 | 3.76×3.05 | 12.70×7.01 | 178 | 121 |

| 10″x8″ | 250×200 | 273.0×219.1 | 4.19×3.76 | 9.27×8.18 | 15.09×12.70 | 216 | 203 |

| 10″x6″ | 250×150 | 273.0×168.3 | 4.19×3.40 | 9.27×7.11 | 15.09×10.97 | 216 | 194 |

| 10″x5″ | 250×125 | 273.0×141.3 | 4.19×3.40 | 9.27×6.55 | 15.09×9.53 | 216 | 191 |

| 10″x4″ | 250×100 | 273.0×114.3 | 4.19×3.05 | 9.27×6.02 | 15.09×8.56 | 216 | 184 |

| 12″x10″ | 300×250 | 323.8×273.0 | 4.57×4.19 | 10.31×9.27 | 17.48×15.09 | 254 | 241 |

| 12″x8″ | 300×200 | 323.8×219.1 | 4.57×3.76 | 10.31×8.18 | 17.48×12.70 | 254 | 229 |

| 12″x6″ | 300×150 | 323.8×168.3 | 4.57×3.40 | 10.31×7.11 | 17.48×10.97 | 254 | 219 |

| 12″x5″ | 300×125 | 323.8×141.3 | 4.57×3.40 | 10.31×6.55 | 17.48×9.53a | 254 | 216 |

| 14″x12″ | 350×300 | 355.6×323.8 | 6.35×4.57 | 11.13×10.31 | 19.05×17.48 | 279 | 270 |

| 14″x10″ | 350×250 | 355.6×273.0 | 6.35×4.19 | 11.13×9.27 | 19.05×15.09 | 279 | 257 |

| 14″x8″ | 350×200 | 355.6×219.1 | 6.35×3.76 | 11.13×8.18 | 19.05×12.70 | 279 | 248 |

| 14″x6″ | 350×150 | 355.6×168.3 | 6.35×3.40 | 11.13×7.11 | 19.05×10.97 | 279 | 238 |

| 16″x14″ | 400×350 | 406.4×355.6 | 6.35×6.35 | 12.70×11.13 | 21.44×19.05 | 305 | 305 |

| 16″x12″ | 400×300 | 406.4×323.8 | 6.35×4.57 | 12.70×10.31 | 21.44×17.48 | 305 | 295 |

| 16″x10″ | 400×250 | 406.4×273.0 | 6.35×4.19 | 12.70×9.27 | 21.44×15.09 | 305 | 283 |

| 16″x8″ | 400×200 | 406.4×219.1 | 6.35×3.76 | 12.70×8.18 | 21.44×12.70 | 305 | 273 |

| 16″x6″ | 400×150 | 406.4×168.3 | 6.35×3.40 | 12.70×7.11 | 21.44×10.97 | 305 | 264 |

| 18″x16″ | 450×400 | 457×406.4 | 6.35×6.35 | 14.27×12.70 | 23.83×21.44 | 343 | 330 |

| 18″x14″ | 450×350 | 457×355.6 | 6.35×6.35 | 14.27×11.13 | 23.83×19.05 | 343 | 330 |

| 18″x12″ | 450×300 | 457×323.8 | 6.35×4.57 | 14.27×10.31 | 23.83×17.48 | 343 | 321 |

| 18″x10″ | 450×250 | 457×273.0 | 6.35×4.19 | 14.27×9.27 | 23.83×15.09 | 343 | 308 |

| 18″x8″ | 450×200 | 457×219.1 | 6.35×3.76 | 14.27×8.18 | 23.83×12.70 | 343 | 298 |

| 20″x18″ | 500×450 | 508×457 | 6.35×6.35 | 15.09×14.27 | 26.19×23.83 | 381 | 368 |

| 20″x16″ | 500×400 | 508×406.4 | 6.35×6.35 | 15.09×12.70 | 26.19×21.44 | 381 | 356 |

| 20″x14″ | 500×350 | 508×355.6 | 6.35×6.35 | 15.09×11.13 | 26.19×19.05 | 381 | 356 |

| 20″x12″ | 500×300 | 508×323.8 | 6.35×4.57 | 15.09×10.31 | 26.19×17.48 | 381 | 346 |

| 20″x10″ | 500×250 | 508×273.0 | 6.35×4.19 | 15.09×9.27 | 26.19×15.09 | 381 | 333 |

| 20″x8″ | 500×200 | 508×219.1 | 6.35×3.76 | 15.09×8.18 | 26.19×12.70 | 381 | 324 |

| 24″x20″ | 600×500 | 610×508 | 6.35×6.35 | 17.48×15.09 | 30.96×26.19 | 432 | 432 |

| 24″x18″ | 600×450 | 610×457 | 6.35×6.35 | 17.48×14.27 | 30.96×23.83 | 432 | 419 |

| 24″x16″ | 600×400 | 610×406.4 | 6.35×6.35 | 17.48×12.70 | 30.96×21.44 | 432 | 406 |

| 24″x14″ | 600×350 | 610×355.6 | 6.35×6.35 | 17.48×11.13 | 30.96×19.05 | 432 | 406 |

| 24″x12″ | 600×300 | 610×323.8 | 6.35×4.57 | 17.48×10.31 | 30.96×17.48 | 432 | 397 |

| 24″x10″ | 600×250 | 610×273.0 | 6.35×4.19 | 17.48×9.27 | 30.96×15.09 | 432 | 384 |

Note: The thickness is available with Sch5, Sch10, Sch30, Sch40, Sch80, Sch120, Sch160, STD, XS, XXS, 5S, 10S, 40S, 80S, etc.

- Complex diversion system: Used in industrial scenarios where the main pipeline needs to divert into two branch pipes of different diameters at the same time (such as multi-output chemical reactors and energy station cooling systems).

- Pressure grading control: Suitable for pipe networks that require differentiated regulation of branch flow and pressure (such as main production lines distributed to equipment of different specifications).

- Key industries: Petrochemical, power transmission, ship piping, and other high-pressure/high-sealing requirement fields.

- Diameter Division Precision: Free combination of the main pipe and the branch pipe specifications (e.g., 24”×10”) to realize the exact flow distribution.

- Structural reliability:Has a pressure capacity equivalent to that of seamless pipes of the same specification, so it is very strong nd can bear high pressure and vibration.

- Seal tightness: The welding joint is permanently free of leakage, which is suitable for sealing over corrosive and high temperature media.

- Carbon steel (ASTM A234 WPB)basic grade with a wide range of material variety and very suited to standard working conditions.

- Stainless Steel (304/316L): Resistance to corrosion, appropriate for high hygiene requirements of food, pharmaceutical, and other industries.

- Global Compatible: Meets ISO and ASME B16 global standards. 9, to ensure the interchangeability and installation time of the system .

- Surface Protection Customization:

- Normal Environment: Black paint coating for rust prevention.

- Highly Corrosive Environment: Hot-dip galvanizing or acid washing and passivation treatment.

- Graded Packaging Solution:

- Small Size (≤6″): Bundled with steel straps, with corner protection for collision prevention.

- Large Size (>6″): Customized wooden boxes for individual protection, filled with shock-absorbing materials inside.

- Smart Identification:

- Outer boxes marked with main/branch pipe diameters (e.g., DN200xDN100), material codes, and flow direction arrows.

- Moisture-proof warning labels affixed to indicate storage conditions.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.