HOT PRODUCTS TAGS

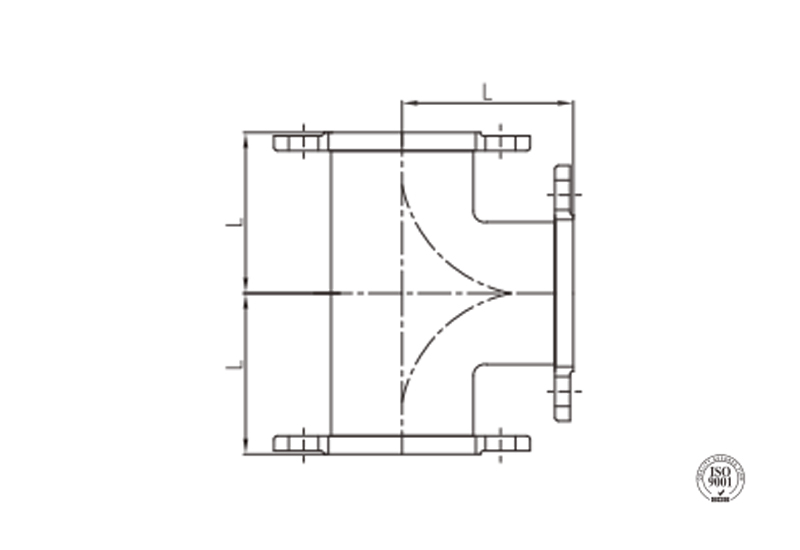

Flanged straight tee (Equal tee)

·Standard: ANSI / UL 213C, EN 1092 ISO

·Material: Ductile iron

·Flanged end:

EN 1092-2, PN10 / PN 16 / PN 25,

RF or ANSI B16.1 Class 125,

B16.42 Class 150, FF or RF

·Rated pressure: 300 – 500 psi

·Surface: Red or blue painting

·Size range: 3″ – 24″

description

Flanged straight tee (Equal tee) is a kind of equal-diameter three-way pipe fitting with flange connection structure. The three interface dimensions are the same and distributed in a straight line. The branch connection of equal-diameter pipelines is achieved through flange connection

Specification

Available size

| Size | Center to end | ||

| Inch | DN | mm | L(mm) |

| 3″ | 80 | 88.9 | 165 |

| 4″ | 100 | 114.3 | 180 |

| 6″ | 150 | 165.1 | 220 |

| 8″ | 200 | 219.1 | 260 |

| 10″ | 250 | 273 | 350 |

| 12″ | 300 | 323.9 | 400 |

| 14″ | 350 | 355.6 | 425 |

| 16″ | 400 | 406.4 | 450 |

| 18″ | 450 | 457.2 | 475 |

| 20″ | 500 | 508 | 500 |

| 24″ | 600 | 609.6 | 550 |

application

- Industrial Pipe Network Large T-shaped branch, with three the same diameter at ends that form a straight line specifically for medium-diameter pipes in high-pressure systems such as petrochemical and energy system).

- High sealing requirements: It is suitable for the pipe system that has a strict requirement on the sealability, such as steam, flammable and explosive objects, prevent leakage.

- Modular installation: assembled by flange bolt, quick to install and remove, convenient for system maintenance or expansion and transformation.

advantages

1. One-piece casting: ANSI/EN/ISO certified high pressure resistant ductile iron, 300-500 psi rated pressure tolerant- for tough working environments.

2. Unimpeded design and Zero flow resistance: Even diameter straight-through comes with an attempt to ensure linear fluid circulation and without the cause of turbulent energy loss;

3. Flexible flange compatibility : Designed to fit American Standard (ANSI FF/RF), European Standard (EN PN10 /16/25) Flanges for project worldwide.

4. Red/blue epoxy coating, long-lasting corrosion protection with good wear- and chemical medium resistance. Supports 3”-24”(DN80-DN600)

5. range of pipe diameters: suitable for needs in-line connections use on industrial main and branch pipework

packing

- Flange Face Ultimate Protection:

- RF Flange: +Cohesive rubber pad (tail) with steel guard plate, silicone plugs to isolate the bolt holes;

- FF flange: Scratch resistant PE film+honeycomb cardboard cushioning layer.

- Heavy-duty wooden box packaging:

- ≤12″: Secure a single piece in a sturdy wooden box embedded with foam;

- >12″: Segmented, disassemblable package with flange interfaces packed separate and tagged with mating numbers.

- For transportation use, boxes are printed with lifting point markings, pressure rating warnings and QR codes (scan to access the flange compatibility chart) and supplied with anti-tip brackets for larger items.

Available size

| Size | Center to end | ||

| Inch | DN | mm | L(mm) |

| 3″ | 80 | 88.9 | 165 |

| 4″ | 100 | 114.3 | 180 |

| 6″ | 150 | 165.1 | 220 |

| 8″ | 200 | 219.1 | 260 |

| 10″ | 250 | 273 | 350 |

| 12″ | 300 | 323.9 | 400 |

| 14″ | 350 | 355.6 | 425 |

| 16″ | 400 | 406.4 | 450 |

| 18″ | 450 | 457.2 | 475 |

| 20″ | 500 | 508 | 500 |

| 24″ | 600 | 609.6 | 550 |

- Industrial Pipe Network Large T-shaped branch, with three the same diameter at ends that form a straight line specifically for medium-diameter pipes in high-pressure systems such as petrochemical and energy system).

- High sealing requirements: It is suitable for the pipe system that has a strict requirement on the sealability, such as steam, flammable and explosive objects, prevent leakage.

- Modular installation: assembled by flange bolt, quick to install and remove, convenient for system maintenance or expansion and transformation.

1. One-piece casting: ANSI/EN/ISO certified high pressure resistant ductile iron, 300-500 psi rated pressure tolerant- for tough working environments.

2. Unimpeded design and Zero flow resistance: Even diameter straight-through comes with an attempt to ensure linear fluid circulation and without the cause of turbulent energy loss;

3. Flexible flange compatibility : Designed to fit American Standard (ANSI FF/RF), European Standard (EN PN10 /16/25) Flanges for project worldwide.

4. Red/blue epoxy coating, long-lasting corrosion protection with good wear- and chemical medium resistance. Supports 3”-24”(DN80-DN600)

5. range of pipe diameters: suitable for needs in-line connections use on industrial main and branch pipework

- Flange Face Ultimate Protection:

- RF Flange: +Cohesive rubber pad (tail) with steel guard plate, silicone plugs to isolate the bolt holes;

- FF flange: Scratch resistant PE film+honeycomb cardboard cushioning layer.

- Heavy-duty wooden box packaging:

- ≤12″: Secure a single piece in a sturdy wooden box embedded with foam;

- >12″: Segmented, disassemblable package with flange interfaces packed separate and tagged with mating numbers.

- For transportation use, boxes are printed with lifting point markings, pressure rating warnings and QR codes (scan to access the flange compatibility chart) and supplied with anti-tip brackets for larger items.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.