HOT PRODUCTS TAGS

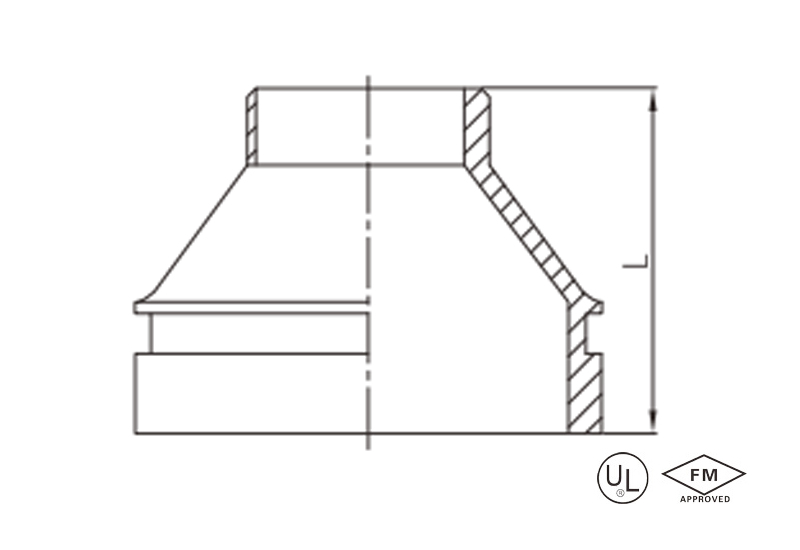

Grooved concentric reducer with male threaded outlet

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Thread run: Male thread, NPT / BSPT

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 2″×1″ – 4″×3″

description

Grooved concentric reducer with male threaded outlet is a concentric reducer with different pipe diameters at both ends and overlapping centerlines. The outlet end is designed with an external thread and is used to connect pipes of different pipe diameters and adapt to external thread components

Specification

Available size

| Size | End to end | ||

| Inch | DN | mm | L(mm) |

| 2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 64 |

| 2″ × 1-1/4″ | 50 × 32 | 60.3 × 42.4 | 64 |

| 2″ × 1-1/2″ | 50 × 40 | 60.3 × 48.3 | 64 |

| 2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 64 |

| 2-1/2″ × 1-1/4″ | 65 × 32 | 73.0 × 42.4 | 64 |

| 2-1/2″ × 1-1/2″ | 65 × 40 | 73.0 × 48.3 | 64 |

| 2-1/2″ × 2″ | 65 × 50 | 73.0 × 60.3 | 64 |

| 2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 64 |

| 3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 64 |

| 3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 64 |

| 3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 64 |

| 3″ × 2-1/2″ | 80 × 65 | 88.9 × 73.0 | 64 |

| 4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 76.1 |

| 4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 76.1 |

| 4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 76.1 |

| 4″ × 2-1/2″ | 100 × 65 | 114.3 × 73.0 | 76.1 |

| 4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 76.1 |

application

- Direct connection modification: Specifically designed for systems that require simultaneous pipe diameter changes and external thread connection to equipment. External thread branches are directly screwed into equipment such as filters and valves, suitable for industrial equipment rooms and pump room integration modifications.

- Efficient use of space: The concentric diameter change structure is compact, suitable for narrow areas such as pipe galleries and equipment bases, reducing the risk of leakage caused by transition pieces.

- High-Pressure Low-Flow Control: Designed for hydraulic systems and cooling circulation pipelines requiring precise control of low-flow branches, achieving integrated pipe diameter reduction and direct equipment connection.

advantages

- Three-in-one functional integration:

- Concentric reducer: Coaxial alignment ensures smooth fluid transition and reduces energy loss by 30%;

- Groove Connection: Quick snap-fit connection at both ends of the main pipe, with seismic resistance and pressure rating of 300-500 psi;

- External Threaded Branch Pipe (NPT/BSPT): Directly screws into the equipment’s female port, eliminating leakage from adapters.

- Industrial-Grade Reliability:

- Ductile iron one-piece casting (ASTM A536), resistant to water hammer impacts and high-frequency vibrations;

- Minute-level installation:

- Groove interfaces eliminate welding/flange alignment, and external threaded branch pipes complete equipment connection in 30 seconds, tripling efficiency;

- Environmental adaptability:

- Red paint/hot-dip galvanized surface treatment resists corrosion from moisture and chemical media, suitable for -30°C to 150°C operating conditions.

packing

- External Thread Ultimate Protection:

- Threaded sections are inserted into custom plastic sleeves and filled with anti-rust wax; silicone bumpers are installed at the ends;

- Groove ends are covered with PE anti-scratch film, and the cone is wrapped with a bubble pad cushioning layer;

- Anti-Rolling Layered Packaging:

- ≤3″: 12 pieces per box, secured with honeycomb cardboard dividers, with threaded ends facing inward to prevent collisions;

- >3″: Each piece is nested in an EPS foam mold, with an octagonal pressure-resistant cardboard box on the outside;

- Anti-error smart labeling:

- Boxes are printed with “External Thread ↑ Do Not Press” warning labels and diameter change direction arrows (large end → small end);

- Includes a QR code sticker (to access the external thread equipment compatibility chart and installation video).

Available size

| Size | End to end | ||

| Inch | DN | mm | L(mm) |

| 2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 64 |

| 2″ × 1-1/4″ | 50 × 32 | 60.3 × 42.4 | 64 |

| 2″ × 1-1/2″ | 50 × 40 | 60.3 × 48.3 | 64 |

| 2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 64 |

| 2-1/2″ × 1-1/4″ | 65 × 32 | 73.0 × 42.4 | 64 |

| 2-1/2″ × 1-1/2″ | 65 × 40 | 73.0 × 48.3 | 64 |

| 2-1/2″ × 2″ | 65 × 50 | 73.0 × 60.3 | 64 |

| 2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 64 |

| 3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 64 |

| 3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 64 |

| 3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 64 |

| 3″ × 2-1/2″ | 80 × 65 | 88.9 × 73.0 | 64 |

| 4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 76.1 |

| 4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 76.1 |

| 4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 76.1 |

| 4″ × 2-1/2″ | 100 × 65 | 114.3 × 73.0 | 76.1 |

| 4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 76.1 |

- Direct connection modification: Specifically designed for systems that require simultaneous pipe diameter changes and external thread connection to equipment. External thread branches are directly screwed into equipment such as filters and valves, suitable for industrial equipment rooms and pump room integration modifications.

- Efficient use of space: The concentric diameter change structure is compact, suitable for narrow areas such as pipe galleries and equipment bases, reducing the risk of leakage caused by transition pieces.

- High-Pressure Low-Flow Control: Designed for hydraulic systems and cooling circulation pipelines requiring precise control of low-flow branches, achieving integrated pipe diameter reduction and direct equipment connection.

- Three-in-one functional integration:

- Concentric reducer: Coaxial alignment ensures smooth fluid transition and reduces energy loss by 30%;

- Groove Connection: Quick snap-fit connection at both ends of the main pipe, with seismic resistance and pressure rating of 300-500 psi;

- External Threaded Branch Pipe (NPT/BSPT): Directly screws into the equipment’s female port, eliminating leakage from adapters.

- Industrial-Grade Reliability:

- Ductile iron one-piece casting (ASTM A536), resistant to water hammer impacts and high-frequency vibrations;

- Minute-level installation:

- Groove interfaces eliminate welding/flange alignment, and external threaded branch pipes complete equipment connection in 30 seconds, tripling efficiency;

- Environmental adaptability:

- Red paint/hot-dip galvanized surface treatment resists corrosion from moisture and chemical media, suitable for -30°C to 150°C operating conditions.

- External Thread Ultimate Protection:

- Threaded sections are inserted into custom plastic sleeves and filled with anti-rust wax; silicone bumpers are installed at the ends;

- Groove ends are covered with PE anti-scratch film, and the cone is wrapped with a bubble pad cushioning layer;

- Anti-Rolling Layered Packaging:

- ≤3″: 12 pieces per box, secured with honeycomb cardboard dividers, with threaded ends facing inward to prevent collisions;

- >3″: Each piece is nested in an EPS foam mold, with an octagonal pressure-resistant cardboard box on the outside;

- Anti-error smart labeling:

- Boxes are printed with “External Thread ↑ Do Not Press” warning labels and diameter change direction arrows (large end → small end);

- Includes a QR code sticker (to access the external thread equipment compatibility chart and installation video).

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.