HOT PRODUCTS TAGS

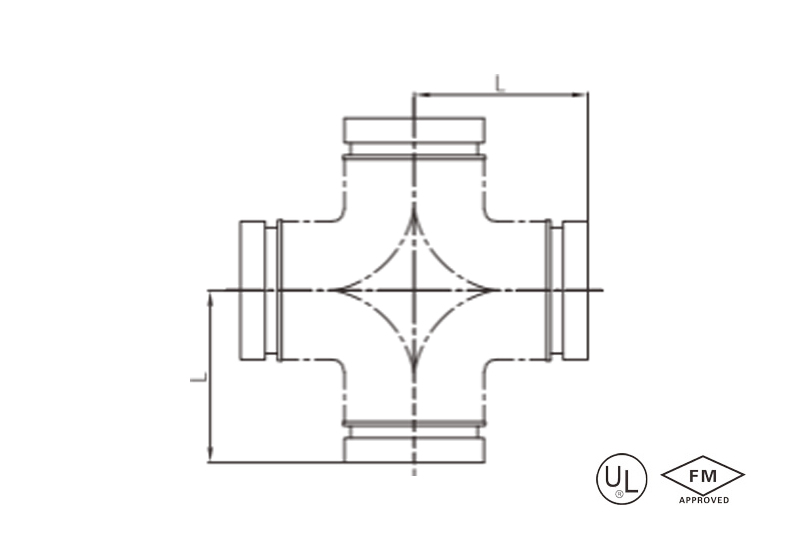

Grooved straight cross (Equal cross)

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 1-1/4″ – 12″

description

Grooved straight cross (Equal cross) is an equal-diameter four-way pipe fitting. The four interfaces have the same pipe diameter and are vertically distributed in a cross shape, which is used to achieve cross-shaped branch connections of equal-diameter pipelines

Specification

Available size

Size | Center to end | ||

Inch | DN | mm | L(mm) |

1-1/4″ | 32 | 42.4 | 70 |

1-1/2″ | 40 | 48.3 | 70 |

2″ | 50 | 60.3 | 70 |

2-1/2″ | 65 | 73.0 | 76 |

2-1/2″ | 65 | 76.1 | 76 |

3″ | 80 | 88.9 | 86 |

4″ | 100 | 114.3 | 101 |

5″ | 125 | 139.7 | 124 |

5″ | 125 | 141.3 | 124 |

6″ | 150 | 165.1 | 140 |

6″ | 150 | 168.3 | 140 |

8″ | 200 | 219.1 | 175 |

10″ | 250 | 273.0 | 215 |

12″ | 300 | 323.9 | 254 |

application

- Material: multi-directional diversion hub to adapt to the medium-caliber pipe in fire syetem more than 300mm and four-hub with perpendicular cross-shaped branch connections on HVAC three same diameter portages, for distributing balanced fluids in equal ratio.

- Small space layout: It is suitable for limited spaces such as machine room and pipe gallery, which can replace multiple tee combinations to optimize the utilization of pipe space.

- Expansion node for system: suitable for pipeline network extension and bidirectional expansion projects, such as waterworks and industrial circulation system renovations.

advantages

1. Cross Center Design for Efficient Flow Diversion: Cross-shaped equal diameter flow-through design keeps a minimal resistance fluid flow to prevent traditional diversion loss of turbulent energy.

2. UL/FM listed pipe groove clamp connection, 300-500 psi working pressure, water hammer and vibration conditions resistant.

3. Radical Installation Simplification: There is no requirement for welding and flange alignment; four interfaces can be connected at the same time, saving 70% of construction duration.

4. Long-term corrosion protection Hot-dip galvanized surface treatment or red paint, which can resist corrosion by moisture and chemical media for more than 50 years.

5. More sizes coverage: 1-1/4″ to 12″ (DN32-DN300) meet the core nodes application of small and medium-sized industrial piping networks.

packing

- Four-way interface protection:

- Each port is covered with PE anti-scratch film + EVA foam sleeve, with custom plastic brackets installed at the crossings to prevent collisions;

- Smart layered packaging:

- ≤6″: 4 pieces per box, ports are staggered and nested in reinforced cardboard boxes with honeycomb cardboard;

- >6“: Each piece is secured with a ”well” shaped wooden frame, with the main body suspended to avoid damage from transportation vibrations.

- Anti-misinstallation Identification System:

- Boxes printed with 3D flow direction diagrams and pressure rating warning labels;

- QR codes provided for scanning to access installation positioning guidelines, preventing misaligned interface installation.

Available size

Size | Center to end | ||

Inch | DN | mm | L(mm) |

1-1/4″ | 32 | 42.4 | 70 |

1-1/2″ | 40 | 48.3 | 70 |

2″ | 50 | 60.3 | 70 |

2-1/2″ | 65 | 73.0 | 76 |

2-1/2″ | 65 | 76.1 | 76 |

3″ | 80 | 88.9 | 86 |

4″ | 100 | 114.3 | 101 |

5″ | 125 | 139.7 | 124 |

5″ | 125 | 141.3 | 124 |

6″ | 150 | 165.1 | 140 |

6″ | 150 | 168.3 | 140 |

8″ | 200 | 219.1 | 175 |

10″ | 250 | 273.0 | 215 |

12″ | 300 | 323.9 | 254 |

- Material: multi-directional diversion hub to adapt to the medium-caliber pipe in fire syetem more than 300mm and four-hub with perpendicular cross-shaped branch connections on HVAC three same diameter portages, for distributing balanced fluids in equal ratio.

- Small space layout: It is suitable for limited spaces such as machine room and pipe gallery, which can replace multiple tee combinations to optimize the utilization of pipe space.

- Expansion node for system: suitable for pipeline network extension and bidirectional expansion projects, such as waterworks and industrial circulation system renovations.

1. Cross Center Design for Efficient Flow Diversion: Cross-shaped equal diameter flow-through design keeps a minimal resistance fluid flow to prevent traditional diversion loss of turbulent energy.

2. UL/FM listed pipe groove clamp connection, 300-500 psi working pressure, water hammer and vibration conditions resistant.

3. Radical Installation Simplification: There is no requirement for welding and flange alignment; four interfaces can be connected at the same time, saving 70% of construction duration.

4. Long-term corrosion protection Hot-dip galvanized surface treatment or red paint, which can resist corrosion by moisture and chemical media for more than 50 years.

5. More sizes coverage: 1-1/4″ to 12″ (DN32-DN300) meet the core nodes application of small and medium-sized industrial piping networks.

- Four-way interface protection:

- Each port is covered with PE anti-scratch film + EVA foam sleeve, with custom plastic brackets installed at the crossings to prevent collisions;

- Smart layered packaging:

- ≤6″: 4 pieces per box, ports are staggered and nested in reinforced cardboard boxes with honeycomb cardboard;

- >6“: Each piece is secured with a ”well” shaped wooden frame, with the main body suspended to avoid damage from transportation vibrations.

- Anti-misinstallation Identification System:

- Boxes printed with 3D flow direction diagrams and pressure rating warning labels;

- QR codes provided for scanning to access installation positioning guidelines, preventing misaligned interface installation.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.