HOT PRODUCTS TAGS

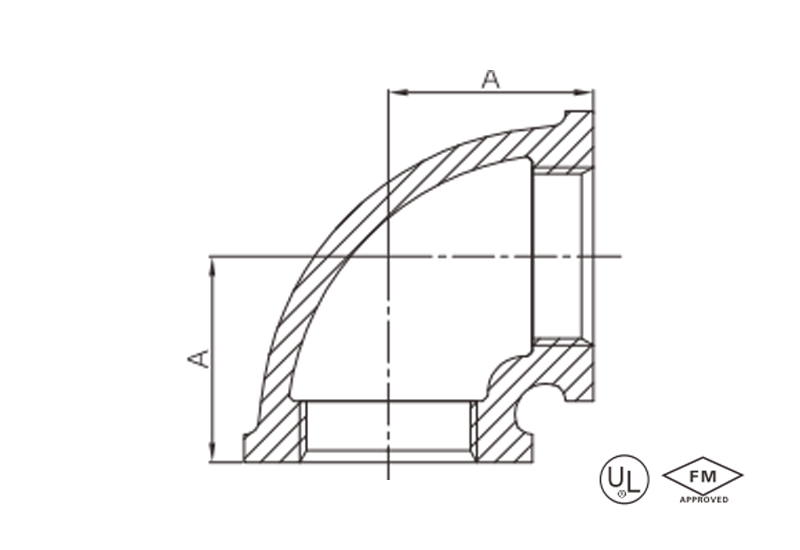

Malleable iron 90° straight elbow

·Standard: ANSI/ASME B16.3

UL/FM

·Material: Malleable iron ASTM A197

·Thread: NPT

·W.pressure: Class 150, 300 psi (-29°C to 66°C)

Class 300, 1000 / 1500 / 2000 psi

(-29°C to 66°C)

·Surface: Black iron / hot dip galvanized

·Size Range: 3/8″ —6″ (Class 150)

1/4″ —4″ (Class 300)

description

Malleable iron 90° straight elbow, precise right-angle steering, tough and impact-resistant, suitable for rapid industrial pipeline connection.

Specification

Available size

SIZE | A | ||

INCH | DN | MM | MM |

3/8” | 10 | 17.1 | 24.1 |

1/2″ | 15 | 21.3 | 28.5 |

3/4″ | 20 | 26.7 | 33.3 |

1″ | 25 | 33.4 | 38.1 |

1-1/4″ | 32 | 42.2 | 44.5 |

1-1/2″ | 40 | 48.3 | 49.3 |

2″ | 50 | 60.3 | 57.2 |

2-1/2″ | 65 | 73 | 68.6 |

3″ | 80 | 88.9 | 78.2 |

4″ | 100 | 114.3 | 96.3 |

6″ | 150 | 168.3 | 130.3 |

1/4” | 8 | 13.7 | 23.9 |

3/8” | 10 | 17.1 | 26.9 |

1/2″ | 15 | 21.3 | 31.8 |

3/4″ | 20 | 26.7 | 35.6 |

1″ | 25 | 33.4 | 41.4 |

1-1/4″ | 32 | 42.2 | 49.3 |

1-1/2″ | 40 | 48.3 | 54.1 |

2″ | 50 | 60.3 | 63.5 |

2-1/2″ | 65 | 73 | 74.7 |

3″ | 80 | 88.9 | 85.9 |

4″ | 100 | 114.3 | 114 |

application

- High-pressure equipment interfaces: air compressors, hydraulic system inlets and outlets, right-angle bends capable of withstanding high pressures of 1000-2000 psi (Class 300).

- Precision instrumentation piping: pressure gauges, flow meters, and connecting branches, with NPT threads ensuring leak-free sealing.

- Industrial steam piping: Temperature range from -29°C to 66°C, suitable for low-pressure steam pipes in boiler rooms (Class 150).

- Mobile equipment piping: Generator sets, construction machinery, threaded connections for quick assembly and disassembly, resistant to vibration deformation.

- Corrosive environment retrofitting: Hot-dip galvanized plates for coastal factories and chemical plants with saltwater piping, black iron plates suitable for dry indoor environments.

advantages

- Overpressure Dual Safety:

- Class 150: Economical, meets standard 300 psi system requirements;

- Class 300: High-pressure version, withstands 2000 psi burst pressure without failure, increasing safety redundancy by 50%.

- Earthquake-resistant and crack-resistant design: Malleable cast iron (ASTM A197) has better ductility than ordinary cast iron, increasing impact resistance by 30%.

- Zero-Leakage Threads: NPT tapered threads with self-sealing design, no additional packing tape required (UL/FM certified).

- Full-scenario compatibility:

- Covers all sizes from 1/4“ to 6”, from small instrumentation tubing (1/4“) to industrial mainlines (6”);

- Hot-dip galvanized coating >85μm, salt spray test >720 hours without rusting.

- 30-second quick installation: Threaded connections can be directly tightened, saving 95% of welding time.

packing

- Thread Ultimate Protection:

- Each threaded end is coated with food-grade anti-rust oil and fitted with a double-layer PE + silicone cap;

- The elbow body is wrapped in pearl cotton to prevent brittle fractures caused by transportation impacts.

- Smart Packaging System:

- ≤2 inches: 50 pieces per box, with internal compartment paper trays + desiccants, and external boxes marked with pressure rating labels (150/300);

- >2 inches: Single-piece wooden box with lid, featuring an embedded high-density EVA mold for suspended shock absorption.

- Anti-counterfeiting and Traceability Solution:

- Product body laser-engraved with pressure rating (e.g., “CLASS 300”);

- NFC chip inside the box, allowing mobile phone scanning to view UL/FM certification certificates.

- Large Special Packaging:

- 6-inch bends use removable steel frame boxes with rubber anti-slip nails on the bottom;

- Wooden boxes with built-in temperature and humidity recorders, with transport data accessible via the cloud.

Available size

SIZE | A | ||

INCH | DN | MM | MM |

3/8” | 10 | 17.1 | 24.1 |

1/2″ | 15 | 21.3 | 28.5 |

3/4″ | 20 | 26.7 | 33.3 |

1″ | 25 | 33.4 | 38.1 |

1-1/4″ | 32 | 42.2 | 44.5 |

1-1/2″ | 40 | 48.3 | 49.3 |

2″ | 50 | 60.3 | 57.2 |

2-1/2″ | 65 | 73 | 68.6 |

3″ | 80 | 88.9 | 78.2 |

4″ | 100 | 114.3 | 96.3 |

6″ | 150 | 168.3 | 130.3 |

1/4” | 8 | 13.7 | 23.9 |

3/8” | 10 | 17.1 | 26.9 |

1/2″ | 15 | 21.3 | 31.8 |

3/4″ | 20 | 26.7 | 35.6 |

1″ | 25 | 33.4 | 41.4 |

1-1/4″ | 32 | 42.2 | 49.3 |

1-1/2″ | 40 | 48.3 | 54.1 |

2″ | 50 | 60.3 | 63.5 |

2-1/2″ | 65 | 73 | 74.7 |

3″ | 80 | 88.9 | 85.9 |

4″ | 100 | 114.3 | 114 |

- High-pressure equipment interfaces: air compressors, hydraulic system inlets and outlets, right-angle bends capable of withstanding high pressures of 1000-2000 psi (Class 300).

- Precision instrumentation piping: pressure gauges, flow meters, and connecting branches, with NPT threads ensuring leak-free sealing.

- Industrial steam piping: Temperature range from -29°C to 66°C, suitable for low-pressure steam pipes in boiler rooms (Class 150).

- Mobile equipment piping: Generator sets, construction machinery, threaded connections for quick assembly and disassembly, resistant to vibration deformation.

- Corrosive environment retrofitting: Hot-dip galvanized plates for coastal factories and chemical plants with saltwater piping, black iron plates suitable for dry indoor environments.

- Overpressure Dual Safety:

- Class 150: Economical, meets standard 300 psi system requirements;

- Class 300: High-pressure version, withstands 2000 psi burst pressure without failure, increasing safety redundancy by 50%.

- Earthquake-resistant and crack-resistant design: Malleable cast iron (ASTM A197) has better ductility than ordinary cast iron, increasing impact resistance by 30%.

- Zero-Leakage Threads: NPT tapered threads with self-sealing design, no additional packing tape required (UL/FM certified).

- Full-scenario compatibility:

- Covers all sizes from 1/4“ to 6”, from small instrumentation tubing (1/4“) to industrial mainlines (6”);

- Hot-dip galvanized coating >85μm, salt spray test >720 hours without rusting.

- 30-second quick installation: Threaded connections can be directly tightened, saving 95% of welding time.

- Thread Ultimate Protection:

- Each threaded end is coated with food-grade anti-rust oil and fitted with a double-layer PE + silicone cap;

- The elbow body is wrapped in pearl cotton to prevent brittle fractures caused by transportation impacts.

- Smart Packaging System:

- ≤2 inches: 50 pieces per box, with internal compartment paper trays + desiccants, and external boxes marked with pressure rating labels (150/300);

- >2 inches: Single-piece wooden box with lid, featuring an embedded high-density EVA mold for suspended shock absorption.

- Anti-counterfeiting and Traceability Solution:

- Product body laser-engraved with pressure rating (e.g., “CLASS 300”);

- NFC chip inside the box, allowing mobile phone scanning to view UL/FM certification certificates.

- Large Special Packaging:

- 6-inch bends use removable steel frame boxes with rubber anti-slip nails on the bottom;

- Wooden boxes with built-in temperature and humidity recorders, with transport data accessible via the cloud.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.